By Jim Hingst

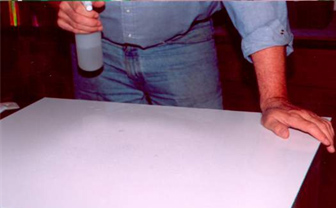

While the rule of thumb among professional installers is to always apply vinyl graphics ‘dry,’ there are some exceptions where the correct way to apply vinyl to a flat plastic surface is ‘wet’ instead, using a commercial-grade application fluid.

When vinyl graphics are installed to a plastic sign face using an application fluid, many tiny bubbles will result, but these will ‘breathe out’ from under the film and disappear. This is preferable to dry-applying vinyl films with an aggressive adhesive system that can cause the graphics to ‘pre-adhere’ to a substrate, which means the vinyl sticks before the installer wants it to, leaving him/her stuck with a graphics disaster.

A commercial-grade application fluid—such as Rapid Tac, Action Tac, Splash or Quick Stick, from various manufacturers—will help avoid these pre-adhesion problems by allowing the installer to ‘float’ the graphic onto the surface and reposition it without distortion until the panel is registered to the right location.

It is important to note these commercial-grade fluids work better than the concoctions signmakers commonly formulate themselves, by mixing water, dishwashing detergent and isopropyl alcohol, because they promote faster vinyl adhesion to the substrate.

It is impossible to duplicate the consistency of the commercial-grade products in a sign shop. Dishwashing soaps contain additives—such as surfactants, emulsifiers, moisturizers and perfumes—that are detrimental to the adhesive. Surfactants, for example, may cause bonding failure and edge lifting.

Commercial-grade application fluids can seem a little pricey, so some signmakers are prompted to extend their supply by adding water—but if they dilute their application fluid, they will also dilute its adhesion-promoting characteristics.

Jim Hingst is business development manager for RTape, which manufactures pressure-sensitive tapes and films. This article is adapted with permission from his blog, Hingt’s Sign Post. For more information, visit www.hingstssignpost.blogspot.ca.