By Stephen Montgomery

Fibre optics may be best-known to the public for their broad use in residential Internet and other telecommunications services, as they can transmit more data across longer distances than copper- or wire-based cabling. They are also increasingly being implemented for lighting applications, however, including sign and display illumination.

An optical fibre is a thin and flexible tube, made of either glass or plastic, that can carry light from one end to the other. It may be installed inside a cable jacket or externally from a cable (i.e. ‘individually’).

Fibre optic lighting has proven practical for a wide range of industrial, automotive, military, aerospace, medical and scientific uses, but has also found its way into store display cases, swimming pools and spas, landscaping, offices, casinos, holiday decorations, toys and consumer products. Indeed, research shows the overall value of the worldwide market for fibre optic lighting grew to US$312 million in 2016.

While the use of fibre optics in signage is still in its infancy, this could change quickly. The process of assembling, testing and manufacturing fibre optic lighting products already allows for mass production capabilities. Over the next few years, the average prices of these products will be driven lower by these production efficiencies, as well as by quality controls, higher yields, greater competition (in terms of both markets and technologies), improvements in sales, marketing and distribution and other factors. As such, the technology will move on from the ‘development’ and ‘introduction’ stages in the sign industry and into the ‘growth’ stage of its product life cycle (PLC).

Opening new applications

Optical fibres can illuminate a sign by emitting light from their sides, providing an effect similar to neon. They are not nearly as heavy as traditional sign lighting technologies, however, so the labour involved in constructing and installing a sign is reduced, as is the cost of transporting it.

Further savings are achieved over the long term. Optical fibres are durable and do not degrade under normal conditions. Also, since light—not heat—is being sent along the fibre, typically the only maintenance required is at the source of the light, e.g. changing the lamp.

Optical fibre-based signs can display single static or multiple digital messages in more than 256 colours and provide exceptional visual clarity. The main market driver behind their increased adoption, however, is the ability to create and install illuminated displays in entirely new forms and locations, thanks to the attributes of the technology’s unique mix of components:

- The optical fibres themselves, whether made of glass or of a ‘plastic optical fibre’ (POF) polymer.

- The illumination source, whether based on light-emitting diodes (LEDs), halogen or metal halide.

- The related hardware and fittings.

By way of example, optical fibre lighting can operate safely in wet installations, allowing signs to be integrated into swimming pools and fountains. Also, POFs can be woven into carpets and other textile-based surfaces, so as to create illuminated fabric graphics.

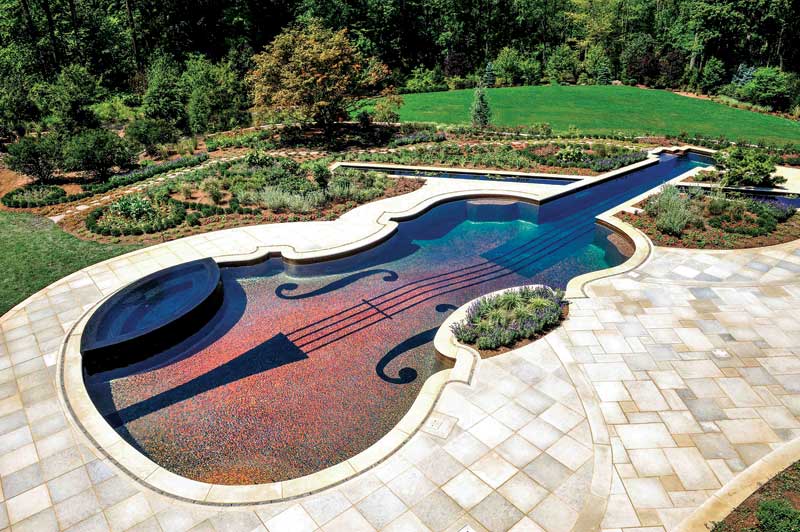

In this violin-shaped pool, 5,760 fibre optic components interlinked with the tiles delineate the lap lanes by day and light up as the ‘strings’ at night. In addition, a 107-m (350-ft) long fibre optic rope lighting detail illuminates the entire boundary.

Photo courtesy Cipriano Landscape Design

Indeed, the use of optical fibres in signs opens up a whole new range of possibilities, limited only by designers’ and fabricators’ artistic creativity and imagination. Sign shops that are open to including fibre optics in their ‘tool box’ can establish a clear advantage over their competition.

Illuminators

According to Universal Fiber Optic (UFO) Lighting, which manufactures glass fibres, an illuminator—or ‘light engine’—can be thought of as the interface between the electrical supply and the optical fibres. It is a separate unit that contains the lamp or LEDs, ‘feeds’ light through the fibres and, as such, can be set up in a centralized location, a fair distance from the actual sign.

This is why fibre optics can, as mentioned, illuminate signs in wet applications. The illuminator is the only component of the system that houses electricity and can become warm to the touch, so it must be kept in a dry location, but then the optic fibres can stretch out into wet environments, even submerged underwater. The illuminator may also include additional control mechanisms for special lighting effects, such as colour changes, pulsing and twinkling.

Many illuminators for fibre optic systems use a Digital Multiplex (DMX) controller. Originally designed to control light dimmers, this now-standard technology has supported the rise of ‘intelligent lighting,’ such as Glasbau Hahn’s systems for museums, where the illumination of a particular area is reduced or turned off completely when it is not occupied by visitors or staff. Other non-lighting functions can also be handled by DMX systems, such as micro-area climate control for display cases.

Thank you for the insight. I made a search and led me to this post, now it’s 2024, why isn’t this product seeing the light in signage or at least I’m not seeing it 🙂