By Jerry Hill and Luigi Cristicini

Any experienced producer of wide-format displays knows lamination is a valuable step of the process, as it can increase the durability and enhance the visible colour gamut of high-end printed graphics. Lamination equipment and consumables can also boost profits, however, by answering the needs raised by current trends and new opportunities in the world of graphic finishing.

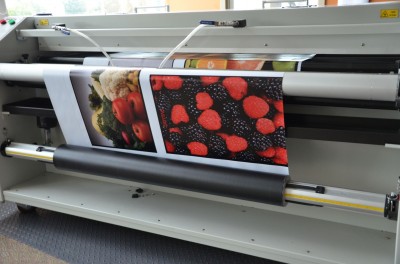

Roll-to-roll lamination

Many sign shops today are producing vehicle wraps, for example, and given the competitive and time-sensitive nature of the market, they are looking for equipment that can simplify the process. One way they can upgrade their capabilities is with a roll-to-roll laminator.

Simply put, roll-to-roll lamination involves overlaminating a series of printed graphics and rolling them onto a core at the back of the laminator. This requires a machine with sufficient unwind and take-up shafts to complete the process, which is generally a cut above an entry-level laminator because it ensures better tracking.

For this reason, when shopping around for a new, upgraded laminator, it is important to see an actual demonstration of the unit as it completes the roll-to-roll cycle and verify it offers tension control on the supply and take-up shafts, as well as a repeatable pinch-point pressure control and gauge for measuring purposes.

Another feature to consider is a heat-assist top roller, which can speed up the curing rate of the adhesive. This helps answer the market demand for more immediacy in service.

Further, when laminated graphics are rolled onto a core, they can more easily be transported to their installation site without suffering from kinks, damage or dirt. Typically, only one person is required to set them up.

For all of these reasons, using roll-to-roll lamination allows jobs to be completed with reduced manual labour costs, in a shorter timeframe and with a much higher chance of success, yielding higher profits.

Face-mounting graphics

Another trend taking off today in the graphics marketplace is face-mounting graphics, which involves applying an image to the second surface (i.e. inside face) of a clear substrate, such as acrylic. This way, a passerby looks through both the clear substrate and an optically clear adhesive to see the graphics.

Face-mounting graphics involves applying an image to the inside surface of a clear substrate. Photo courtesy Ask Guy (AG) Event Graphics

The production process has been around for many years, but there has lately been a surge of inquiries across the sign industry. Face-mounting graphic applications include standard and backlit menu boards, damage-protected directional signs and wall décor, whether framed, hung or mounted on standoffs.

Face-mounting graphics involves a high degree of difficulty. The images and adhesives must be perfect, free of any dirt or bubbles.

This need for perfection has caused many graphics producers to shy away from the process, but this just leaves more potential profit on the table for those who are willing to endure the steep learning curve. That said, there are some basic steps to success:

- Make sure the work environment is very clean. Dust is the graphics’ enemy—one speck can ruin the print.

- For the best results, print the images on a very smooth-surfaced type of media.

- Use a roller laminator to apply an optically clear, double-sided adhesive to the face of the printed image.

- Mount the image to the substrate by progressively removing the second release liner as it passes back through the laminator.

The complete procedural details are more involved, of course, but worth the time and effort to learn. Face-mounting graphics can put a lot of extra money in a signmaker’s pocket, as the completed images can garner three to four times the profit margin of an average print, if done well.