By Jeff Fassett

While light-emitting diodes (LEDs) have taken over channel letter applications that were previously illuminated with neon, sign shops still face challenges in designing complete LED layouts inside the letters for optimized esthetics. After all, sign fabricators had decades to establish best practices for neon, while LEDs are still relatively new to the industry.

One of the ways LED suppliers helped usher the immature technology to industry acceptance was by designing layouts for their customers. That may have been necessary in the earliest days of LED-illuminated channel letters, but although this practice has endured, many signmakers are now realizing they can better control their projects and be ‘faster to market’ if they use design software to come up with their own layouts in-house.

Transition from neon to LEDs

When LEDs first arrived on the sign industry ‘scene’ for use in channel letters and sign cabinets, there was a significant backlash against the technology. Both neon and fluorescent lighting had been used successfully for many years, with well-established sign design techniques to achieve optimal brightness levels, as well as standardization across suppliers that made it easy for sign shops to switch brands and not have to start from scratch. There was an especially large group of professionals in the sign industry who were trained and highly experienced in the art of neon signage.

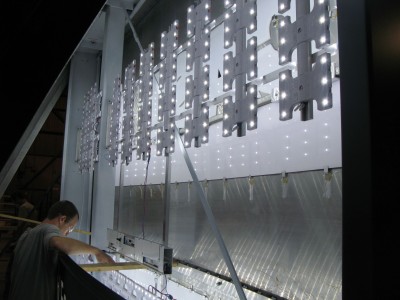

As signmakers have tested different methods, ‘best practices’ have emerged for designing LED layouts.

When LED technology was new to the sign industry, suddenly everything was different. Each supplier made different claims about such attributes as brightness, power consumption, colour temperature, longevity, etc. As a result, each system of LEDs had to be laid out differently, in terms of the number and position of modules, to achieve a favourable result in comparison to neon or fluorescent illumination. And there were already many more suppliers of LEDs than of neon or fluorescent lamps.

Sign shop employees were eager to try the new technology, but did not yet have the right knowledge or tools to design optimal layouts, so the suppliers stepped in and offered to handle layouts for them at no cost.

While this tactic was certainly a practical way to encourage the adoption of LEDs, it did nothing to educate signmakers. Instead, it created a sort of ‘black box’ situation, where sign shops would send design files to the supplier and then get a result back, as though LEDs layouts were inherently complex and mysterious and could not be revealed to their users. Even minor changes had to be sent back through the process again, since signmakers did not themselves have any means to change layouts directly.

So, while this process was technically free for the sign shops, it did entail costs in terms of slower response times to customers, limited flexibility in making changes and, of course, a lack of knowledge about the particulars of each job.