By Peter Saunders

Wide-format ultraviolet-curing (UV-curing) flatbed printers represent one of the fastest-growing segments of the graphics industry. Given the scale of the investment, it is important for signmakers to choose the right type of equipment, both for today and for the future. It can be difficult, however, to make the right choice between all of the models currently available.

Some sign shops already produce large-format digitally printed graphics, while others seek to add flatbed capabilities to their existing screenprinting, offset, packaging and/or other in-house production processes. To select the most suitable model for their business, they will need to make sense first of the complexities of UV flatbed printing technology.

The capital cost of a UV printer, which is usually amortized over several years, is only one of the criteria to consider when calculating the machine’s total cost of ownership (TCO). The following factors also need to be counted:

- Inks, lamps, electricity and other consumables, based on the printer’s rate of consumption.

- Parts and service.

- Labour (i.e. printer operation).

- Print finishing.

- Costs related to floor space used up by the printer and its work area.

- The printer’s earning potential, based on its estimated production volume.

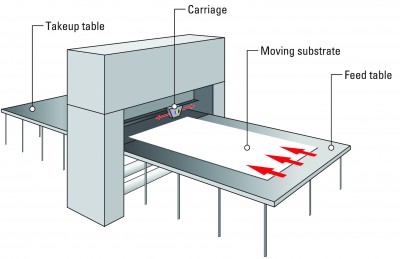

With a ‘hybrid’ flatbed printer, the printing zone is stationary and the substrate moves through it.

Understanding a digital printer’s TCO is essential before a sign shop can sell its graphic output profitably. The calculation must balance the potential to produce as much revenue as possible from a single machine with the maximum physical space that can be allotted within the production department. Printer manufacturers should provide real-world models for their products’ return on investment (ROI).

System designs

For flatbed printing, there are basically two system designs: ‘moving media’ and ‘true flatbed.’

Moving media

In a ‘moving media’ machine, the printing zone is stationary and, as the descriptor suggests, the substrate is moved through it, just like with a roll-to-roll printer. With no moving gantry, it is very important for the media to be moved through the printer accurately, for the duration of the printing process.

This design concept is found among ‘hybrid’ printers, which are often designed primarily for roll-based media, but can also support some rigid media after being fitted with removable tables and/or a belt drive system. These features allow rigid media to be transported through a stationary printing area.

This format allows printer manufacturers to add rigid-media functionality at a relatively low capital cost. The other advantage for sign shops is ‘two-in-one’ printing, as the same device can be used to print on both flexible and rigid media.