A call to expand the digital printing paradigm

by marika_gabriel | 27 September 2024 11:00 am

How DTF printers can amplify product diversity and unleash new offerings for sign shop owners

By Ginny Mumm

[1]

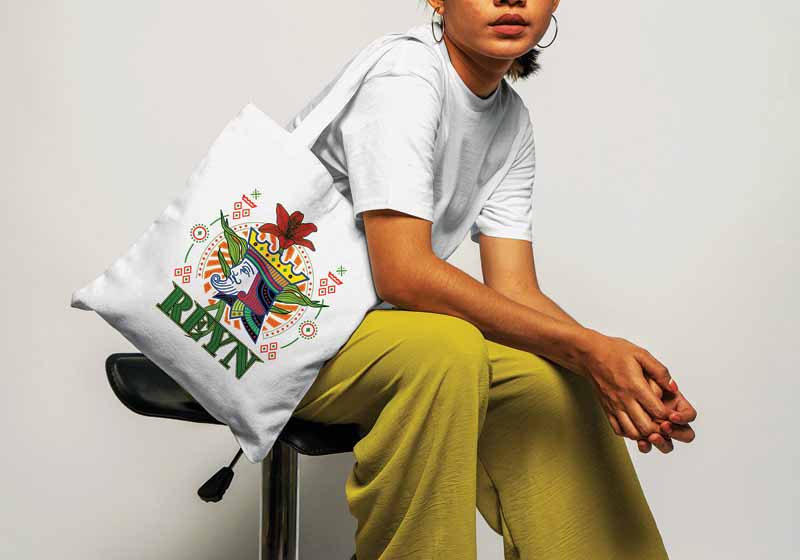

[1]Adding customized apparel can provide a high-margin additional revenue stream for shop owners. Photos courtesy Roland DGA

It is no secret the market demand for personalized apparel is continuing to rise. In fact, according to Grand View Research, the decorated apparel market globally hit $28.98 billion (C$36.2 billion) in 2023, and is expected to grow at a compound annual growth rate (CAGR) of 13 per cent from 2024-2030.1

One of the fastest growing production methods for custom apparel printing is direct-to-film (DTF) production. DTF offers fast, high-quality production of one-off or short-run customized apparel products. Once the province of apparel manufacturers and mall kiosks, these devices are now being integrated into sign shops as a way to broaden product ranges and create custom apparel in-house.

To find out more about this popular textile production method, we talked with Roland DGA application specialist Mike Davis.

Why should print service providers (PSPs) consider bringing apparel production

in-house?

Mike Davis (MD): Sign shop owners today are often asked if they provide custom shirts, hats, jackets, and tote bags. Many are outsourcing this production to another shop, losing the opportunity to provide what can be high-quality, high-margin products themselves. Today’s DTF technology allows shop owners to bring full-colour, on-demand custom apparel production in-house.

Screen printers are also taking advantage of DTF technology to print smaller runs or samples. Advanced Raster Imaging Processor (RIP) software can produce the same colour options as screen printing, including half-tones, with much less setup time.

How are manufacturers addressing the market’s growing need for on-demand custom apparel production?

[2]

[2]With production orders, it’s possible to achieve a much higher hourly output with today’s DTF devices.

MD: Manufacturers are responding with efficient, affordable DTF solutions that can keep up with the needs of shops for high-quality on-demand production. First-tier manufacturers also offer excellent service and support that ensure consistent up-time for these devices.

Modern DTF printers are compact and easy to use, and don’t require users to pre-treat fabrics. The basic workflow has only a few steps. For example, if you are printing one 304.8 mm x 304.8-mm (12 in. x 12-in.) image onto a tee-shirt, the process of printing the graphic onto transfer film, coating it with shaking powder, melting the powder under a heat press for the recommended time at the recommended temperature, and then heat pressing the graphic onto a garment and removing the film backing can be as quick as 10 minutes.

With production orders, it’s possible to achieve a much higher hourly output with today’s DTF devices.

What types of apparel and textiles can DTF print on?

MD: DTF is a remarkably versatile production platform. While most people are printing on products made of 100 per cent cotton, DTF can also be used to print on 100 per cent polyester as well as poly blends, denim, and on some types of nylon.

The most common application is on tee-shirts; however, DTF works equally well on tote bags, aprons, caps, and sports shirts. It offers PSPs the chance to expand their product line for clients. Instead of just offering sports banners, decals, and yard signs, with DTF, a shop owner can provide jerseys, parent shirts, hats, and other types of team apparel.

[3]

[3]Instead of just offering sports banners, decals, and yard signs, with DTF, a shop owner can provide jerseys, parent shirts, hats, and other types of team apparel.

What should PSPs look for in a DTF printer?

MD: It’s important to look for a manufacturer providing robust equipment that can deliver consistent colour and high-definition output over time. It’s also key to find a company that stands behind their devices with a good warranty. You want to ensure your machine will perform optimally for as long as possible, and that should you need a part or service, your manufacturer will have parts and support available.

Some DTF printers offer additional features to help ensure vibrant, detailed graphics. For example, Roland DG’s DTF printer—the VersaSTUDIO BY-20—boasts advancements that not only maximize colour richness and accuracy, but also make this compact yet powerful desktop device incredibly simple to operate. The BY-20 can also be used for traditional print and cut applications as well as for heat transfer graphics. Additionally, some manufacturers offer the other DTF system components needed—the inks, transfer paper, and powder—to provide users with a complete solution.

What types of software are manufacturers offering for this market?

MD: Most DTF manufacturers are now including RIP software with their devices. Additional software is required to create the art.

Roland DG’s VersaSTUDIO line is specifically designed to be easy to use. The BY-20 includes a license for a version of FlexiDesigner as well as RIP software. This can help with creating vector images which can then be sent for outputting and allows for users to import their design from other software.

What role does sustainability play in DTF production?

[4]

[4]While most people are printing on products made of 100 per cent cotton, DTF can also be used to print on 100 per cent polyester as well as poly blends, denim, and on some types of nylon.

MD: The ability to print on-demand helps with sustainability. With DTF production, you don’t have to stock your prints or deal with large inventories that may not sell. You can produce exactly what your clients want, when they want it.

What do you see ahead for DTF printing? What innovations are in the pipeline?

MD: I think the market for DTF will continue to get stronger. It’s an accessible and affordable way for shop owners to broaden their product offerings and meet more of their clients’ needs in-house. The printers themselves will undergo minor tweaks to further increase print speeds. There may also be a movement toward a four-printhead machine rather than the current standard of one or two printheads.

There will also be improvements coming with the production components, including inks, powders, and films. Hot peel film is becoming popular now.

Specialty films such as glitter films and glow-in-the-dark films are being launched as well, so I expect to see improvements in those types of materials as they mature in the market. I have also come across samples of textured effect films, which we should start seeing more of going forward.

Ginny Mumm is a freelance consultant for digital inkjet printer/cutter provider Roland DGA. For more information, visit www.rolanddga.com.

Notes

1. Read the Market Analysis Report by Grand View Research here: https://www.grandviewresearch.com/industry-analysis/decorated-apparel-market[5]

- [Image]: https://www.signmedia.ca/wp-content/uploads/2024/09/Fig1_DTF.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2024/09/Fig1_DigitalPrintingCollage.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2024/09/Fig11_DTF.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2024/09/Fig8_DTF.jpg

- https://www.grandviewresearch.com/industry-analysis/decorated-apparel-market: https://www.grandviewresearch.com/industry-analysis/decorated-apparel-market

Source URL: https://www.signmedia.ca/a-call-to-expand-the-printing-paradigm/