-

Choosing the right tool

Fabricating parts on their computer numerical control (CNC) router, POP49 expanded their product line to offer a myriad of promotional products, working with materials like plywood, polyvinyl chloride (PVC) and acrylic plastics, aluminum, as well as exotic woods and printed materials.

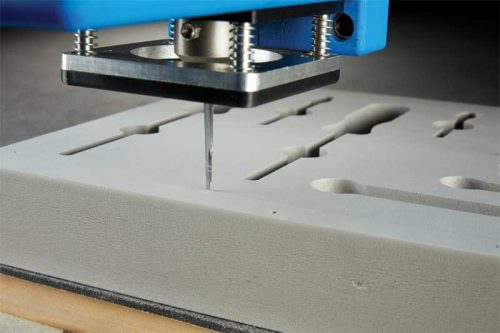

To achieve the best cut quality, it is important to always choose the tool with the shortest flute length that will cut through the material being used. This helps reduce cutter deflection and chatter. For example, the longer the router bit, the more it will deflect. When Ricky Pacheco bought his first CNC router in 2010, his company, POP49, in Mississauga, Ont., went from designing and manufacturing experiential assets for marketing clients to becoming a leader in innovative POP displays across North America, Mexico, and Puerto Rico.

Creating eye-popping POP displays

“I quickly realized it [the CNC router] to be the most versatile and useful tool in our collection of equipment,” says Pacheco, the company’s founder/director. “Being able to design and manufacture on demand has opened up a huge amount of potential to invent and prototype ideas at high quality and speed.”

With a background in marketing and mechanics, he started his business in 1989, combining his skills and experience to develop unique, high quality products for successful business branding. Fabricating parts on his CNC router helped him expand his product line to a myriad of promotional products, working with materials like plywood, polyvinyl chloride (PVC) and acrylic plastics, aluminum, as well as exotic woods and printed materials.

Like all signmakers, Pacheco is proud of his work, calling the level of repeatability and quality as superb.

“Having jobs duplicated years after they were first created and having them come out identical and perfect makes the client confident in our ability to sustain longer drawn out programs,” he says.

Selecting the right tool for the job can make the difference between a perfectly smooth and clean cut, or something that looks like it has been hacked out with a saw.

Along the way, Pacheco realized the importance of designing 3D products. Simultaneous three-axis control is a standard feature on most CNC routers that allows signmakers to cut complex and detailed 3D designs. This is an increasingly popular part of creating POP displays, signmaking, mould making, and many other applications.

“Designing in 3D is key,” says Pacheco. “Being able to show a client what the end product will look like makes all the difference.”

As far as CNC tooling goes, Pacheco recommends a combination of different router bits. He often uses compression, ‘downcut,’ ‘upcut,’ and straight flutes, and relies on the material to dictate which router bit is best. For his POP displays, he prefers ‘downcut’ and straight flutes. Although this means running the machine at a slower pace, he finds the end result to be a cleaner edge finish. He also recommends POP fabricators add a vision system to their inventory which comprises a high-performance camera mounted on the head of the CNC machine. This technology quickly finds and recognizes conventional registration marks, adjusting the machine cutting path as necessary to achieve exact alignment with printed shapes.

With all of his CNC tools and accessories in place, Pacheco enjoys working with his clients to bring their ideas to life.

“Seeing the look on a client’s face when they see something we have created makes everything we do worth it,” he says.

Susan Mattine is the communications and public relations associate for AXYZ Automation Group, a global leading manufacturer of tailored cutting solutions. She can be reached via email at smattine@axyz.com. For more information, visit axyz.com.