Wide-format Printing: A growing market for lenticular displays

by all | 5 January 2013 8:30 am

[1]

[1]This 6 x 1.8-m (20 x 6-ft) mural for Quebecor comprises seven phased 1.2 x 1.8-m (4 x 6-ft.) lenticular tiles, mounted on a 3-mm (0.12-in.) aluminum composite backing and braced with an aluminum frame. Photo courtesy Softmotion

By Guy Brisson

Three-dimensional (3-D) effects are in vogue these days, with advanced technology yielding a deluge of 3-D movies, TVs, video games and cameras. In keeping with this trend, many out-of-home (OOH) and point-of-purchase (POP) marketers are also trying to convey their messages in 3-D to better attract attention. One medium for these efforts has been lenticular imagery, which allows a flat, static sign to achieve the illusion of dimensionality, dynamism and even brief animation.

Lenticular prints are not new; they span back more than 60 years. New generations of substrates, however, have moved what was once a ‘novelty’ process into the reach of a greater number of printing applications. Central to this shift has been the development of a sophisticated digital workflow, which can help commoditize what were previously highly proprietary and expensive techniques.

Nevertheless, high-quality lenticular imaging remains a challenging discipline to master, rather than a simple add-on product line for any comprehensive sign shop or print service provider (PSP).

[2]

[2]Lenticular images were created to serve as product backdrops for a Versace store’s window displays in New York, N.Y. Photos courtesy Margeaux Walter NYC

Creating illusions

A lenticular print is a graphic that is specially designed to work with a lens to allow passersby to view different images from different angles. The graphic is thus a composite of two or more images interlaced together.

The plastic lens is made up of individual lenticules. Based on the viewing angle, each lenticule acts like a magnifying glass, enlarging each portion of the image for display. Working together, the lenticules create the entire range of imagery.

It is because the viewer’s left eye and right eye view printed graphics at slightly different angles that lenticular imagery can create a sense of motion—including up to 1.5 seconds of animation—and depth. The lenticules are positioned vertically to accommodate the necessary bipolar disparity. The human brain then processes the multiple perspectives into a single 3-D image.

In ‘volumetric 3-D’ applications, the images are not only layered like pieces of flat cardboard, but also given fuller shape. This enables both the illusion of depth and more natural contours.

Graphics in motion

With respect to the wide-format digital inkjet printing sector, opportunities for lenticular displays have grown in the POP market, where new poster-size output is constantly needed to help promote newly released products. Advertising agencies have shown great fondness for the benefits of lenticular work.

Today’s shoppers are faced with hundreds of choices as they stroll along retail aisles. In a recent independent study, tests were conducted to measure product sales using static and motion displays. The results showed sales volumes increased by an average of 56 per cent when stores implemented static displays, but up to 107 per cent when using motion displays.

[3]

[3]Short animated sequences can now be conveyed from beginning to end in a single lenticular display.

[4]

[4] [5]

[5] [6]

[6] [7]

[7] [8]

[8]It is therefore not surprising retailers tend to prefer dynamic displays. A three-year independent marketing study surveyed store managers and found 65 per cent of them wanted advertisers’ in-store marketing campaigns to provide motion displays.

The store managers themselves often determine the success or failure of advertising on the basis of installation location. At the retail level, documentation shows 88 per cent of all motion displays achieve prime placements, helping maximize the return on advertising dollars.

In some of these cases, digital signage is implemented, but it is an expensive medium for most POP placements, some of which are not connected directly to an electricity source. Lenticular displays are more easily swapped out with other POP graphics.

In the broader OOH arena, meanwhile, lenticular images have been used for some transit shelter posters and as dynamic portions of billboards. Interest in the medium is also emerging for what signmakers would consider less traditional applications, including museum exhibits, fine art and architectural elements, such as the permanent lenticular murals and wallcoverings that have been installed in large facilities like casinos and airports.

Enhancing production

Traditionally, lenticular images have been produced with lithographic printing presses, which are still effective for producing many pieces quickly; but software, resolutions, inks, alignment tools and extruded lenses have all been improved over the course of the evolution of digital inkjet printing.

[9]

[9]There is a growing interest in lenticular images for fine-art applications. Photo courtesy Softmotion

As a result, it is easier today to produce more complicated graphics and incorporate animated effects. Special software can convert two-dimensional (2-D) images, especially photography, into a 3-D format by mapping and isolating elements within a given scene. Ultraviolet-curable (UV-curable) inks can be used for direct printing of graphics for outdoor signage and permanent indoor displays.

Nonetheless, each lenticular printing professional has his/her own techniques and tricks and has to become a good technician in the field. The learning curve is steep and there will be a lot of wasted prints at the beginning of anyone’s career. Every application is different, requiring its own ‘mini’ research and development (R&D) process, including mockups and proofs. And if a shop introduces lenticular printing into its existing portfolio of services, but only ends up doing it every other month, it will never get very good at it.

Success in the niche lenticular printing market takes more than a good idea and off-the-shelf interlacing software. It requires careful execution of a sophisticated workflow and communication process, whether the result is a small-format direct mail piece or an 18.3-m (60-ft) wide multi-panel mural.

[10]

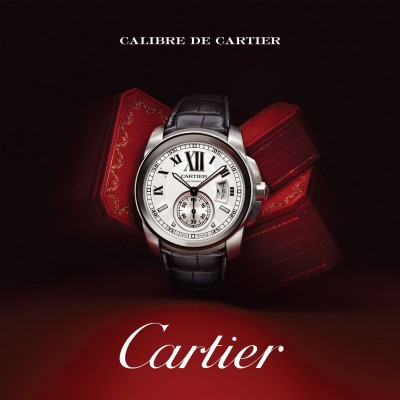

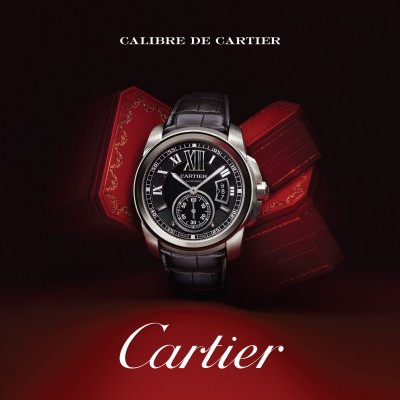

[10]Advertisers have found creative ways to use lenticular capabilities to convey their messages.

[11]

[11]First, a series of images will need to be created with slightly different perspectives. These are then compressed into a single image composed of many narrow stripes, which are then matched to the lenticules of a specially designed plastic sheet.

With today’s digital inkjet technology, the images can now be printed directly onto lenticular sheets made of polyethylene terephtalate glycol-modified (PETG) co-polyester material. (This material can be manufactured to specifications that meet all requirements for safety and food contact.)

Once the graphics are printed in this way, the sheet will display a sequence of different images when viewed from different angle, creating a single visual to present a product or tell a story. As mentioned, this visual can also become part of a larger piece like a billboard, such that 2-D and 3-D elements are mixed together. Designers will need to be very creative to make those applications happen.

Designing for lenses

The lenses are extruded in various sizes, ranging up to 1.2 x 2.4 m (4 x 8 ft). This upper limit dictates how grand-format applications may be achieved, as any larger size will need to comprise an array of lenticular ‘tiles,’ which is very difficult to co-ordinate while maintaining the integrity of the depth effect and animation concept.

The planning alone for such displays is labour-intensive and expensive, requiring specialized craftsmanship and a lot of patience. So, there tend not to be very many real-world grand-format applications of lenticular technology.

Indeed, given the limitations of lenticular displays, it is fair to say 90 per cent of a print’s success is determined at the design stage. The art, after all, must be designed to be compatible with the lenses, with appropriate contrast levels, colour matching and background elements.

If the client demands an image that is not compatible, it is better to walk away from the job before it becomes a visual disaster. That said, the client may simply need to allow a few adjustments to make the artwork effective.

Another issue is lens quality. Even after they are specially extruded, lenses are not perfect. They can create visual distortions if their lenticules are not perfectly straight and parallel. This is especially true with large-format lenses, which fewer extruders can achieve and where distortions will be all the more obvious to the viewer.

From niche to mainstream?

Many printing professionals have moved in and out of lenticular work over the years, but dedicated shops have had to take a longer-term approach. It is still an expensive business to get into, with a niche market to serve, so only a few shops will have enough specialized work coming in every week. Some of these shops compete in even more specific niches, including large-format lenticular displays.

[12]

[12]In point-of-purchase (POP) applications, multiple products can be showcased in the same display.

[13]

[13]Once a shop is properly equipped, however, there are a lot of applications to pursue, including packaging, direct mail and promotional items, all of which can be sold to advertisers. Awareness is still very low, so it is up to specialized shops to help create demand by catching clients’ interest by showing them samples and using other promotional tools. The business risks may be great, but the potential profits are higher than in traditional printing.

There is even a consumer market emerging, where customers provide a series of images—e.g. photos of themselves aging over the years—that can then be integrated into custom lenticular items, such as greeting cards for their relatives. Some shopping malls are even providing on-site photo conversion services.

In terms of wide-format technology, the next step may be direct-to-substrate flatbed printing, which currently can be used only for low-resolution graphics. Printer manufacturers are working on improvements in this area.

With such developments, the world is going to see more and more lenticular prints.

Guy Brisson is founder and owner of Softmotion, which designs and prints lenticular images in Chambly, Que., and a senior executive at its U.S. parent company, AD+/Softmotion. For more information, visit www.softmotion.com[14].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/quebecoronsite3.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/IMG_0629.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/000_0005_Frame-1-copy.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/000_0004_Frame-2-copy.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/000_0003_Frame-3-copy.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/000_0002_Frame-4-copy.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/000_0001_Frame-5-copy.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/000_0000_Frame-6-copy.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/fineart2.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/pix1.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/pix2.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/cartier1.jpg

- [Image] : http://www.signmedia.ca/wp-content/uploads/2014/02/cartier2.jpg

- www.softmotion.com: http://www.softmotion.com

Source URL: https://www.signmedia.ca/a-growing-market-for-lenticular-displays/