A how-to guide on leveraging wide-format opportunities

Substrate considerations

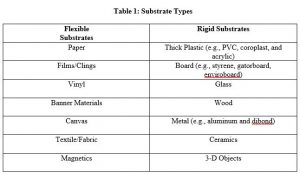

A key benefit of wide-format devices is they can print on a wide variety of media types. Overall, substrates can be rigid or flexible. Printing devices (roll-fed, flatbed, or hybrid) typically dictate the type of substrates (rigid, flexible, or both) that can be used, but there are many media options for each type. It is impossible to list all of the available substrates because there are so many, but the table below provides a high-level description of common substrate types.

Here are some key questions to ask when selecting substrates for various applications:

- Will the print be exposed to sunlight, UV radiation, moisture, or extreme temperatures?

- How long does the print need to last?

- Will the print be displayed more than once?

- Where and how will the print be installed?

- What special effects are required?

Special effects and ink technology

Ongoing advancements in technology and ink are creating new opportunities to produce higher-margin applications that feature special print effects. These premium applications have the potential to ignite sales and accelerate profits. The following is a sampling of effects and techniques that can be considered.

White ink

White ink expands both the range and quality of applications that can be produced. It is becoming increasingly popular, largely due to technological improvements related to opacity and printer productivity. By first printing an opaque white layer, printers can produce stunning images on an array of non-traditional substrates. White ink can also create a strong impact when printing on clear adhesives or dark or metallic substrates.

In addition to enabling printing on a broader array of substrates (including transparent and dark materials), white ink increases the type of work that an organization can add to its service offerings, including the creation of special effects. White ink is often required for package printing and prototyping, as well as for backlit displays and window clings printed on transparent media.

Clear ink

Clear ink can be used to achieve certain visual effects. When clear varnish covers an entire printed sheet for protection or sheen, this is called a flood coating. Alternatively, spot varnish enables you to highlight areas of a printed piece, adding shine and depth to specific elements like a logo or image.