So far, however, direct-to-substrate printing has been somewhat problematic in terms of colour management. It is important to monitor for colour consistency, especially for high-end display applications.

Also, it is important to account for the requirements of a display when considering direct-to-board printing. Many POP graphics need to be applied to in-store surfaces, such as windows, or mounted to lightboxes. If they do not use pressure-sensitive vinyl, then additional mounting films may be required to facilitate adhesion.

Using the proper mounting film can ensure a POP display appears exactly as it is intended to, preventing a black board from showing through, for example, or ensuring backlighting will show through a sign thanks to an optically clear adhesive.

Projection displays

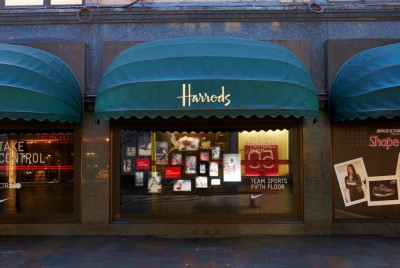

Another promising development in the POP display sector has been the introduction of ‘diffusion’ vinyls and image projection systems that can turn windows and other clear surfaces into digital signage displays. To stand out from the typical video screen, the specialized vinyl materials can be cut on a plotter into unusual shapes, then integrated as touch screens, ‘virtual presenters’ or other dynamic merchandising displays.

One recent development in POP displays has been the introduction of ‘diffuser’ vinyl and image projection systems to turn store windows into digital signage.

Essentially, they serve as rear-projection screens, with a wide viewing angle and high resolution under all in-store brightness levels. As digital signage becomes more ubiquitous as a medium, retailers are looking for new ways to capture shoppers’ attention, so these types of products hold a lot of promise in determining how today’s and tomorrow’s customers will be engaged.

While these films and rear-projection systems are not as simple to install as typical POP graphics are, one advantage is their content can be changed out and updated remotely whenever necessary, thanks to Internet connectivity and cloud-based software, meaning no further effort is required at the store staff level. As installers’ familiarity with this type of technology grows and retailers become more comfortable with it, it is likely more stores will capitalize on its potential in the future.

The way forward

As printers, inks and materials continue to improve and costs, setup times and waste continue to decrease, the POP display market is well-positioned for future success. Retailers have better opportunities than ever before to make their brands and products stand out, with customer-engagement campaigns that use more of their ‘real estate,’ from cash registers to windows, walls and floors.

Jason Yard is marketing manager for MACtac Distributor Products. For more information, visit www.mactac.com.