MTRs in action

Once training is complete and a company’s MTR has been identified as such, he/she must start to change the way certification is handled.

The following documents will be needed:

- ANSI/UL 48 (15th edition).

- Other standards, including UL 879, UL 2151 for neon transformers and power supplies and UL 814 for gas-tube-sign (GTS) cabling.

- UL bulletins for useful information and clarifications.

- Followup service instructions.

- UL sign components manual.

- Label log, listing all current labels, locations and unique file numbers.

- Master Compliance Records (MCRs) for each sign or family of signs.

- Records of tests required for each sign.

- Certification records and compliance documents for test equipment.

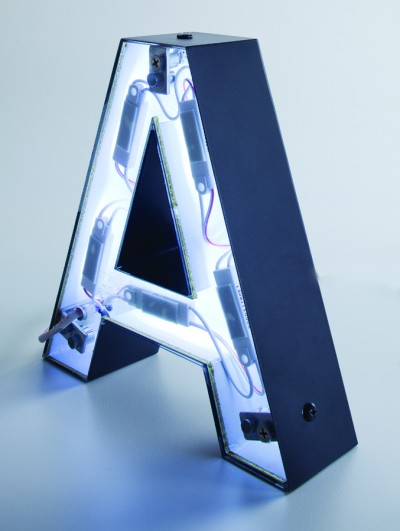

Whether a company has one or numerous MTRs, they will need to lay out the process for making a sign, take photos when it is under construction and document the process as it is completed, assigning a UL listing label. The notes and photos must be kept in a file with the sign’s unique identification (ID) number, with both the file and the label documented in a log.

In late 2012, UL completed an audit of Gemini’s fabricated stainless steel letters, assuring users they meet safety specifications. As a result, the letters come with wiring diagrams, installation instructions and a UL label attesting to their officially listed status.

After the sign is shipped and/or installed, the MTR will place all of the pertinent documents in a file, awaiting the arrival of a followup inspector.

Once the followup inspector has reviewed and cleared the product, the file needs no longer be kept for his/her use. It should be retained, however, as helpful reference information for future service and repairs.

If a sign company has numerous departments and many employees, a single MTR may copy sections of UL 48 related to production and pass them along to department heads. Then, as each head oversees his/her department’s completion of its production tasks, the MTR will need to verify these tasks have been completed as per the standard’s requirements.

Each shop drawing, for example, should be initialed by the MTR and placed in the file with the project’s unique ID number. These shop drawings depicting construction and components will qualify as verification of how the company’s products are built.

Indeed, the major difference in UL’s new certification program is the requirement for the MTR to verify the construction of a sign with documentation, even when that sign is already installed in the field. As such, the MTR needs to be competent in the administration of the standard, detect and correct variations during production and check all phases of construction, in an effort to provide a compliant product before a listing label is attached.

Documents and standards

The MTR must also be proficient in other documents and standards. UL 879 is especially useful, since it contains all of the conditions of acceptability for the parts and pieces needed to construct a compliant product. Thecomponents used in the construction of an electric sign need to be listed, recognized or classified by UL for inclusion in a compliant product, within their own conditions of acceptability. Similarly, UL 2161 contains all of the requirements for transformers and power supplies.

Heico Lighting, based in Saint-Eustache, Que., recalled its Platinum neon power-supply transformers earlier this year because they did not meet UL standards and posed a fire risk. Photo courtesy CPSC

UL will issue bulletins on an ongoing basis to verify and clarify sections of UL 48. A bulletin can even be used to update or change the standard, once the approval of the standard technical panel (STP) has been obtained through a vote in the affirmative.

Followup pages are used to explain to the followup inspector how to interpret the standard, to ensure conformity in the system. These pages are the sole property of UL, however, and should not be used by any other agencies administering the standard.

UL’s sign components manual, often referred to as ‘SAM,’ is used to help select parts and pieces for the assembly of an electric sign. It allows products to be used without having to add them to the components standard or to the procedure described in the company’s file. SAM is updated numerous times each year.

The label log, as already in use, is an inventory of all UL listing labels. It can now be used to track the unique ID numbers that must follow each electric sign.

The MCR is a new document that collects other, existing documents. It must list the product type, customer, unique ID number, date, illumination type (e.g. fluorescent) and sign construction category (e.g. wet location).