Electric Signs: A new standard for certification

by all | 31 May 2013 8:30 am

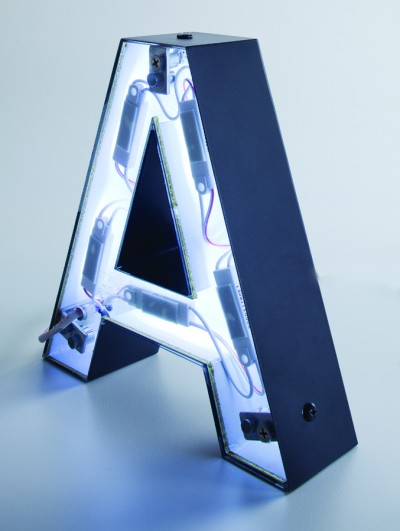

[1]

[1]Photo courtesy RKW Consulting

By Randall K. Wright

Underwriters Laboratories (UL)—an independent, not-for-profit product safety testing and certification organization—began work on the 15th edition of its standard for electric signs 19 years ago, when the project was originally proposed as a bi-national standard for Canada and the U.S. On October 2, 2012, the new update of UL 48 was finally complete and in full effect.

The committee that prepared the new document for submission was comprised equally of Canadian and U.S. members, including representatives of sign companies, electric sign product manufacturers, power supply manufacturers and regulators. Starting in 1994, the committee agreed to meet multiple times each year at convenient locations in both countries.

The first draft was prepared in October 1996. The existing UL 48 standard was updated in April 2003 to acknowledge changes in technology, resulting in a document that could be rearranged to create the 15th edition. It was followed by a more complete and complex draft in May 2004.

It was determined that with various technical deviations—including the differences in high voltages between the two countries, different types of standards and too many product specifications within UL 48—the project would be put on hold until a new standard for electric sign components, UL 879, could be developed.

The 15th edition was finally published as both UL 48 and an American National Standards Institute (ANSI) document with an effective date of September 2, 2011, with an exception of a few sections that would become effective on October 2, 2012.

Certification and training

While the technical requirements generally remain the same, the update involved a complete reorganization of the document to make it more user-friendly.

At the same time, UL has changed its certification procedures, such that it requires subscribers to select a level of compliance based on the needs of each company and its product mix. Under this new Sign Certification Program, there are four different compliance level options.

[2]

[2]UL recently announced it is eliminating all variation notice (VN) fees related to its electric sign certification program. File photo

The new program also requires the training and identification of a manufacturer’s technical representative (MTR) for each facility. There may indeed be numerous MTRs in a facility, but one is the minimum.

MTRs are required to participate in and pass a training session comprising 12 online modules. These are based on the previous, 14th edition of UL 48 and on UL Knowledge Services (formerly known as UL University). A 13th module is now being prepared as an interim conversion to the 15th edition of UL 48, but eventually, all of the training modules will be completely rewritten to align to the current standard.

MTRs in action

Once training is complete and a company’s MTR has been identified as such, he/she must start to change the way certification is handled.

The following documents will be needed:

- ANSI/UL 48 (15th edition).

- Other standards, including UL 879, UL 2151 for neon transformers and power supplies and UL 814 for gas-tube-sign (GTS) cabling.

- UL bulletins for useful information and clarifications.

- Followup service instructions.

- UL sign components manual.

- Label log, listing all current labels, locations and unique file numbers.

- Master Compliance Records (MCRs) for each sign or family of signs.

- Records of tests required for each sign.

- Certification records and compliance documents for test equipment.

Whether a company has one or numerous MTRs, they will need to lay out the process for making a sign, take photos when it is under construction and document the process as it is completed, assigning a UL listing label. The notes and photos must be kept in a file with the sign’s unique identification (ID) number, with both the file and the label documented in a log.

[3]

[3]In late 2012, UL completed an audit of Gemini’s fabricated stainless steel letters, assuring users they meet safety specifications. As a result, the letters come with wiring diagrams, installation instructions and a UL label attesting to their officially listed status.

After the sign is shipped and/or installed, the MTR will place all of the pertinent documents in a file, awaiting the arrival of a followup inspector.

Once the followup inspector has reviewed and cleared the product, the file needs no longer be kept for his/her use. It should be retained, however, as helpful reference information for future service and repairs.

If a sign company has numerous departments and many employees, a single MTR may copy sections of UL 48 related to production and pass them along to department heads. Then, as each head oversees his/her department’s completion of its production tasks, the MTR will need to verify these tasks have been completed as per the standard’s requirements.

Each shop drawing, for example, should be initialed by the MTR and placed in the file with the project’s unique ID number. These shop drawings depicting construction and components will qualify as verification of how the company’s products are built.

Indeed, the major difference in UL’s new certification program is the requirement for the MTR to verify the construction of a sign with documentation, even when that sign is already installed in the field. As such, the MTR needs to be competent in the administration of the standard, detect and correct variations during production and check all phases of construction, in an effort to provide a compliant product before a listing label is attached.

Documents and standards

The MTR must also be proficient in other documents and standards. UL 879 is especially useful, since it contains all of the conditions of acceptability for the parts and pieces needed to construct a compliant product. Thecomponents used in the construction of an electric sign need to be listed, recognized or classified by UL for inclusion in a compliant product, within their own conditions of acceptability. Similarly, UL 2161 contains all of the requirements for transformers and power supplies.

[4]

[4]Heico Lighting, based in Saint-Eustache, Que., recalled its Platinum neon power-supply transformers earlier this year because they did not meet UL standards and posed a fire risk. Photo courtesy CPSC

UL will issue bulletins on an ongoing basis to verify and clarify sections of UL 48. A bulletin can even be used to update or change the standard, once the approval of the standard technical panel (STP) has been obtained through a vote in the affirmative.

Followup pages are used to explain to the followup inspector how to interpret the standard, to ensure conformity in the system. These pages are the sole property of UL, however, and should not be used by any other agencies administering the standard.

UL’s sign components manual, often referred to as ‘SAM,’ is used to help select parts and pieces for the assembly of an electric sign. It allows products to be used without having to add them to the components standard or to the procedure described in the company’s file. SAM is updated numerous times each year.

The label log, as already in use, is an inventory of all UL listing labels. It can now be used to track the unique ID numbers that must follow each electric sign.

The MCR is a new document that collects other, existing documents. It must list the product type, customer, unique ID number, date, illumination type (e.g. fluorescent) and sign construction category (e.g. wet location).

For a smaller sign shop, an MCR may include an assembly of photos taken during production, copies of electrical component invoices, a list of parts used and some related notes. For a larger manufacturer, a work order and shop drawing should suffice, if all of the parts are identified. If unsure, it is always a good idea to take production photos and attach them to the MCR.

When constructing a ‘family’ of like signs, one drawing can be identified and then referenced for all of the other signs.

The construction review should cover the following:

- Frame and enclosure.

- Ventilation openings.

- Sign face and/or panels.

- Moisture resistance and drain holes.

- Grounding and bonding.

- Electrical and thermal spacing.

- Wire routing and support.

- General workmanship (i.e. shaving, sharp edges and de-burring).

- Correct hardware.

- Electrical and supply conductors.

- Installation instructions with the sign.

- Included list of correct components.

There should also be a performance review of the following:

- Mechanical integrity.

- Exclusion of water.

- Strain relief.

- Grounding continuity.

Reorganization and changes

As mentioned, the 15th edition of UL 48 is has also come into effect as an ANSI standard. The document underwent STP review and voting. The most recent review, completed shortly before the October 2012 effective date, focused on a few sections that had been previously overlooked in the review process, including screws, metal thickness, water testing and some wire size requirements.

[5]

[5]Each sign now requires a list or inventory of products used during its fabrication in the sign shop.

In addition to the ID number, each sign now requires a list or inventory of products used in its manufacture, the type of construction and the final installation location. Some of the other notable changes from UL include requirements for certified equipment, including tape measures, calipers, weights and electrical test equipment.

Also as mentioned, the new standard is a reorganization of the old one, with basically the same technical requirements, but with a new layout of information. The changes are based on the bi-national format, with information arranged in sections based on the different departments within a sign manufacturing facility.

Working alongside UL staff, the STP did not simply cut and paste these sections, but instead performed a complete review of newly added technologies, compliance with the National Electric Code (NEC) and new definitions required for clarity. The changes have been made to help ensure safer products and to support different levels of certification based on sign shops’ needs, while still allowing current forms and documentation to continue to be used.

Randall K. Wright operates RKW Consulting, which specializes in neon sign fire prevention, and represents the United States Sign Council (USSC) on UL’s sign industry business panel. For more information, visit www.rkw-consulting.com[6].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/In-production.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/DQ.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/Gemini-FabricatedHaloLitA.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/tft.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/in-production-3.jpg

- www.rkw-consulting.com: http://www.rkw-consulting.com

Source URL: https://www.signmedia.ca/a-new-standard-for-certification/