By Sonia Yooshing

What once started as a small shop in Boucherville, Que., in the ’80s, quickly grew into a 2787-m2 (30,000-sf) large facility in Longueil in 1987. And today, just over three decades later, Access Signs has transformed into a full-service company, providing turnkey signage solutions to clients across North America. From exterior illuminated signs to intricate interior displays, the shop’s state-of-the-art facility is committed to rolling out quality products, no matter the size or complexity. These signmakers take immense pride in their work and strive hard to help brands create lasting first impressions.

Sign Media Canada recently spoke with Young Professional Network’s (YPN’s) vice-president and 2019 International Sign Association (ISA) Elite, Lee Murphy, who is also the senior sales representative at Access Signs, to learn more about the company’s history, its signmaking process, recent projects, and future plans for the business.

Sign Media Canada (SMC): What is the history of the shop? How large is the facility today?

Lee Murphy (LM): Access Signs was founded by Luc Bouchard and Tammi Derkson, who each handled their respective portions of the business—fabrication and sales—before they expanded the business and added an additional partner, Carl Dessureault.

Today, the shop functions primarily as a fabrication unit, with offices in the front for various departments, including sales, project management, design, and estimating. We currently have 40 employees working across eight departments at our 5574-m2 (60,000-sf) large production facility, which permits future expansion in the coming years as technology progresses.

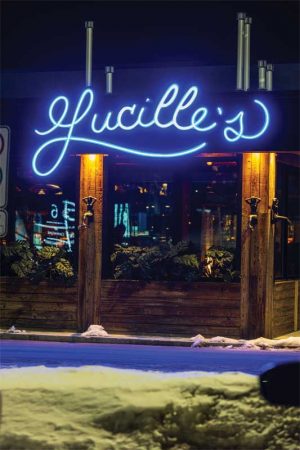

This stunning custom sign for Lucille’s restaurant in Laval, Que., consists of flex light-emitting diodes (LEDs) that illuminate the vintage-style letters, which are painted proprietary blue and installed on all three elevations.

SMC: What type of signage does your shop primarily make?

LM: We specialize in exterior lit signage, including channel letters, lightboxes, and push-through letters, just to name a few. From directional signs to high-rise pylons, we always have a good mix of fabrication projects at any given time.

Our company is also involved with various national signage programs; therefore, quality and uniformity are our top-most priorities. These help us ensure our client’s branding looks the same in British Columbia as it does in New Brunswick.

SMC: What type of projects have you been working on recently?

LM: Alongside our regular national signage programs, we are also working on several city projects, such as pylons, message centres, etc. You will always find multi-tenant pylon projects in the shop, and we normally have one or two being built at all times.

SMC: How much of the signmaking process is handled in-house?

LM: The entire signmaking process is done in-house. Once the design and project specifics are finalized by the creative department, cut files and fabrication details are generated, which are then reviewed by the head of production and his floor manager. Cutting, welding, bending, painting, wiring, graphics, etc., are handled in a chronological order—almost like an assembly line—to ensure an efficient and seamless process from start to finish. Needless to say, quality for us is non-negotiable; therefore, we make sure each step is thoroughly monitored.