Access Signs: Creating a lasting first impression

by | 17 March 2020 12:31 pm

[1]

[1]

By Sonia Yooshing

What once started as a small shop in Boucherville, Que., in the ’80s, quickly grew into a 2787-m2 (30,000-sf) large facility in Longueil in 1987. And today, just over three decades later, Access Signs has transformed into a full-service company, providing turnkey signage solutions to clients across North America. From exterior illuminated signs to intricate interior displays, the shop’s state-of-the-art facility is committed to rolling out quality products, no matter the size or complexity. These signmakers take immense pride in their work and strive hard to help brands create lasting first impressions.

Sign Media Canada recently spoke with Young Professional Network’s (YPN’s) vice-president and 2019 International Sign Association (ISA) Elite, Lee Murphy, who is also the senior sales representative at Access Signs, to learn more about the company’s history, its signmaking process, recent projects, and future plans for the business.

Sign Media Canada (SMC): What is the history of the shop? How large is the facility today?

Lee Murphy (LM): Access Signs was founded by Luc Bouchard and Tammi Derkson, who each handled their respective portions of the business—fabrication and sales—before they expanded the business and added an additional partner, Carl Dessureault.

Today, the shop functions primarily as a fabrication unit, with offices in the front for various departments, including sales, project management, design, and estimating. We currently have 40 employees working across eight departments at our 5574-m2 (60,000-sf) large production facility, which permits future expansion in the coming years as technology progresses.

[2]

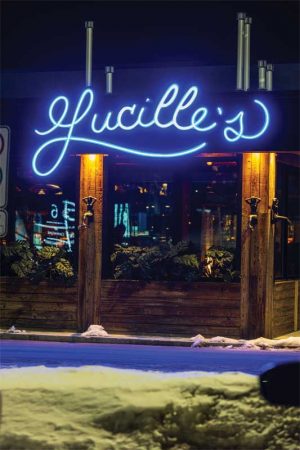

[2]This stunning custom sign for Lucille’s restaurant in Laval, Que., consists of flex light-emitting diodes (LEDs) that illuminate the vintage-style letters, which are painted proprietary blue and installed on all three elevations.

SMC: What type of signage does your shop primarily make?

LM: We specialize in exterior lit signage, including channel letters, lightboxes, and push-through letters, just to name a few. From directional signs to high-rise pylons, we always have a good mix of fabrication projects at any given time.

Our company is also involved with various national signage programs; therefore, quality and uniformity are our top-most priorities. These help us ensure our client’s branding looks the same in British Columbia as it does in New Brunswick.

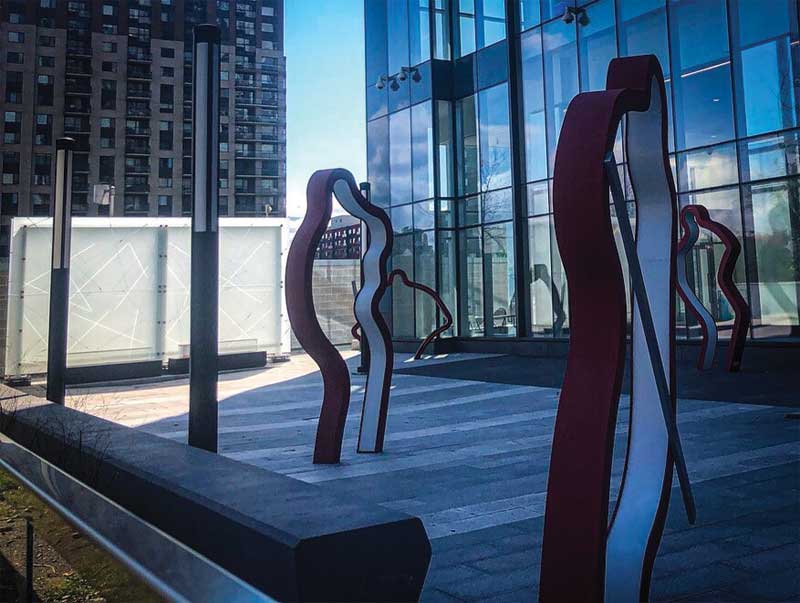

SMC: What type of projects have you been working on recently?

LM: Alongside our regular national signage programs, we are also working on several city projects, such as pylons, message centres, etc. You will always find multi-tenant pylon projects in the shop, and we normally have one or two being built at all times.

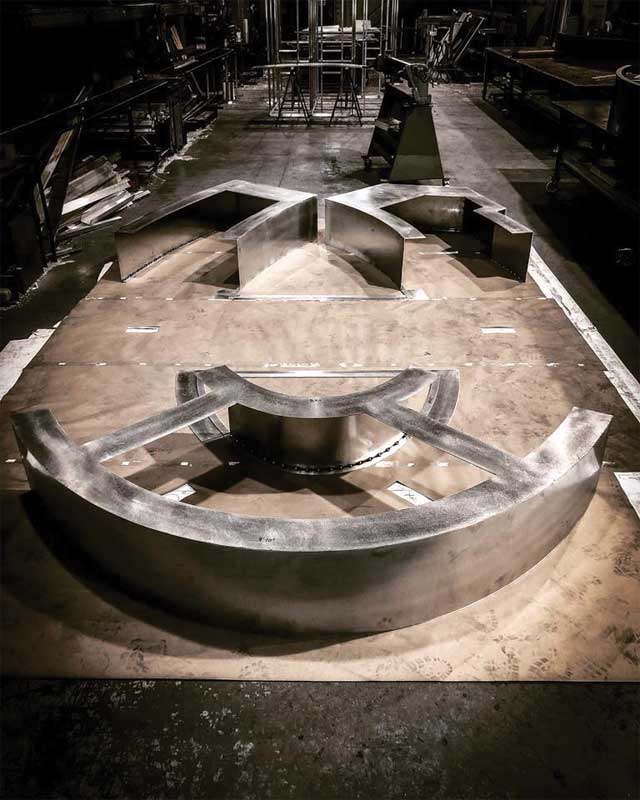

SMC: How much of the signmaking process is handled in-house?

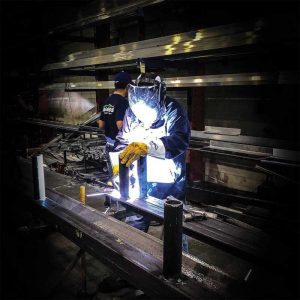

LM: The entire signmaking process is done in-house. Once the design and project specifics are finalized by the creative department, cut files and fabrication details are generated, which are then reviewed by the head of production and his floor manager. Cutting, welding, bending, painting, wiring, graphics, etc., are handled in a chronological order—almost like an assembly line—to ensure an efficient and seamless process from start to finish. Needless to say, quality for us is non-negotiable; therefore, we make sure each step is thoroughly monitored.

[3]

[3]Alongside Access Signs’ regular national signage programs, the creative team is currently working on several multi-tenant pylon projects.

SMC: What tools/equipment do you currently use to complete your sign projects?

LM: We currently have two computer numerical control (CNC) machines—Machitech and Axyz—in the facility. We also have an Accu-Bend channel letter bending machine, a fully-equipped metal shop, and two large-scale paint booths that shoot AzkoNobel, Matthews Paint, and Grip-Gard. The shop also boasts a large-format printer, plotter, and laminator, as well as a range of smaller fabrication-related equipment.

SMC: What does your planning and design process involve?

LM: After an initial consultation with a sales representative, the client information is translated to our design department. Once

the sign code is verified by our in-house permit specialist, the design team goes over the project requirements, including size restrictions, budget, and vision, and creates a proposition based on what they believe would bring the best value to the client and their respective project.

SMC: How is today’s technology changing your business?

LM: We use custom-designed signage software that is proprietary to Access Signs. The program has streamlined many aspects of our business from estimating to project management, fabrication, planning, forecasting, and accounting. It also allows us to stay competitive—the more efficient you are, the better you can service the client. Further, investing in new machinery can make the sign building process faster, more efficient, and reliable, with less downtime. Adopting new technology can also streamline different work processes and eliminate a lot of internal frustration.

SMC: What makes your company unique?

LM: Access Signs has a diverse labour force, and this gives us the freedom to experiment with our ideas. Having a mix, for example, of young professionals and experienced staff in the creative department provides a fresh and technical perspective when creating projects that are unique to the industry. Many of our signs may appear ‘exotic’ to most companies as they are architectural rather than pure signage as it is understood today.

Our uniqueness also lies in our work culture. We value our employees and celebrate their birthdays with cakes, monthly pizza lunches, food trucks, etc.

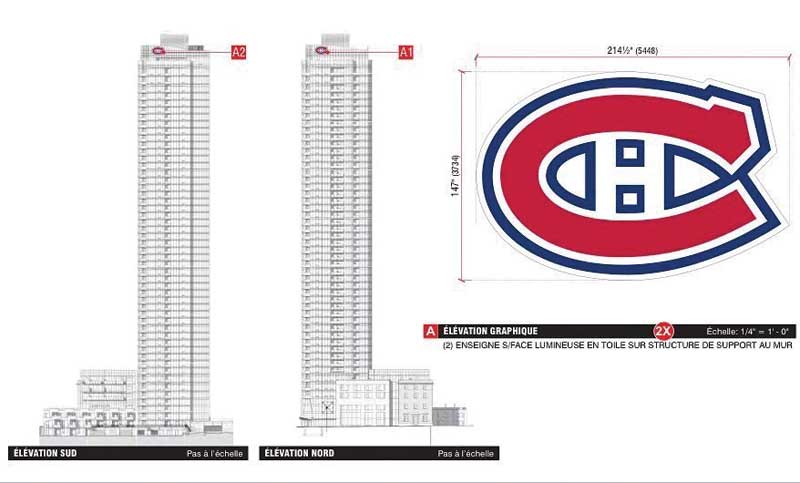

[4]

[4]Once the sign code is verified by the in-house permit specialist, the design team goes over the project requirements, including size restrictions, budget, and vision, and creates a proposition based on what they believe would bring the best value to the client and their respective project.

SMC: What is the key to staying successful in this industry?

LM: The key to staying successful is always putting your client first. You have to be attentive to their needs, find innovative solutions to improve existing signage programs, and above all, be cognizant of the fact that while signage is mostly an afterthought for many people, it is the first thing they see when they walk into a store or restaurant. Therefore, it is important to educate customers about new techniques and provide alternatives to traditional methods. Not only does this approach help clients make an informed choice, but also allows them to make their brand stand out from the rest.

Also, supporting the industry and participating in events can be extremely rewarding for sign professionals.

SMC: What are the future plans for your sign business?

LM: We are currently expanding into various sign-related markets. We also hope to take on many unconventional projects, which can be interesting and challenging at the same time, so these are on our radar.

- [Image]: https://www.signmedia.ca/wp-content/uploads/2020/03/companypĥoto.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2020/03/005A6582-HDR.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2020/03/IMG_5967.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2020/03/IMG_5968.jpg

Source URL: https://www.signmedia.ca/access-signs-creating-a-lasting-first-impression/