Achieving cost-effective colour

by | 16 April 2019 3:40 pm

[1]

[1]By Gudrun Bonte

What constitutes good colour depends on who one is talking to; it is rather subjective, and depends on what it is the customer is willing to pay for. While that measure must not be an excuse for second-rate work, it certainly helps print providers focus on the end result. It is really that simple.

However, large-format printers and sign shops disclose that producing consistent, predictable colour and matching spot colours is a perpetual challenge for them.

Even though there is no excuse for bad colour, in most jobs there are some colours that are critical while others are not. Corporate and brand colours are very important and investing time in getting them right is worthwhile. For these colours, Pantone colour references are needed, but for other parts of the job “memory colours” are acceptable. Memory colours are those that are naturally identified with objects, e.g. apples are generally red, lemons are mostly yellow, limes are usually green. If the job focuses on a particular variety of these fruits, then a fairly wide spectrum of colour variation is considered.

So, honing in on the relevant colours is a way of reducing production costs and time while still producing work to suit the customer’s taste.

It begins with the brief

Asking key questions at the start of the job is crucial in understanding what the customer desires. For example, which colours are important? What is the Pantone reference for the colours? Is there a swatch or example of the desired result? Is there a preferred substrate?

[2]

[2]With this input, printing a job—quickly and profitably—immediately becomes easier, but one must never underestimate the final substrate’s impact on the colour. This, too, needs to be accurately accounted for.

Software harmony

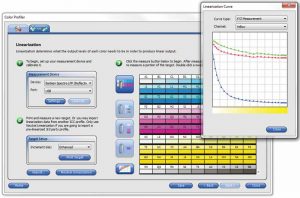

Ensuring the consistency of colour management settings throughout the workflow is critical. The colour settings of the design file one receives should match one’s own design and raster image processor (RIP) software. However, this cannot be done automatically and each program needs to be set manually.

The industry recommends using standard red, green, and blue (sRGB) for red, green, and blue (RGB) input/workspace profiles, and General Requirements for Applications in Commercial Offset Lithography (GRACol) 2006 Coated for cyan, magenta, yellow, and black (CMYK) input.

The other important settings are the International Colour Consortium (ICC) media profiles. Not only do they ensure the desired colour output, but also save ink and extend the longevity of the print; they also guarantee consistency and repeatability.

The correct media profiles should be easy to find and investing time in doing so will pay dividends. Printer manufacturers and resellers have extensive databases of profiles, so do RIP providers and media websites.

Even with this information, it is still possible to produce unsaleable print if the wrong assumptions are made.

Profile settings are specifically tuned not only to the media type, but also to the finish (matte, gloss), ink, print speed, and output device. Therefore, choosing the wrong setting can result in unsaleable waste. If one cannot find the exact substrate, they must choose the closest one possible, keeping the speed and resolution in mind.

[3]

[3]For businesses that perform multiple jobs using the same media, the author recommends building profiles that suit their workflow and equipment; it is not as difficult as many fear.

Hitting the spot

Apart from colour settings, output consistency and reliability, reproducing accurate spot colours is a laborious task for many large-format printers and sign shops. The above recommendations will go a long way in simplifying the process, but to ensure accurate spot colours one can draw on three basic tools. First, one must visually check the colour. Secondly, one should use spot colour matching software, and finally, one must opt for colour measurement devices.

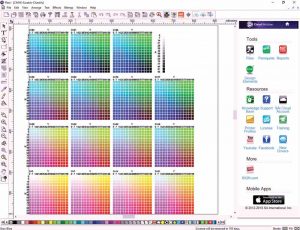

Using the correct methods can make eyeballing a powerful tool. The first step is to evaluate the output’s quality by printing a test sheet and looking at the colour scales. Check the greys: these should be equal proportions of CMY. Next, check the hues; they should be consistent in their transitions, along the colour and across different colours. Finally, look at the primary colours to ensure they are in place.

Pantone colour charts and printed samples can also help achieve accurate spot colours, but the chart must be printed on the same media as the final job, otherwise there will be variations.

Colour matching tools are fast and easy to use. To achieve a Pantone colour, users can refer to the colour mapping chart, which looks like the grid of the game Battleship, and compare it to a swatch printed on their output device on the final media. Then, the X and Y values of the best match can be entered into the system to obtain the desired colour.

[4]

[4]Today, inexpensive colour measurement devices are available that can work with a mobile phone app. These can provide the numerical values of colour in terms of lightness, red/green, yellow/blue (L*a*b) as defined by the International Commission on Illumination (CIE) and the metric for the difference between two colours, Delta-E values. For many companies, investing in higher-end devices will deliver a rapid return on investment (ROI) and significantly reduce ink and media waste.

These methods should become an integral part of the workflow for large-format printers and sign shops and lay the foundation of training new operators. While seemingly basic, they can define the difference between saleable and unsaleable print, and profit and loss.

Gudrun Bonte is the vice-president of product management at SAi, a provider of software solutions for signmaking, digital printing, and computer numerical control (CNC) machining industries. She can be reached via e-mail at info@thinksai.com[5].

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/04/Opener-1.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/04/1.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/04/2.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/04/3.jpg

- info@thinksai.com: mailto:info@thinksai.com

Source URL: https://www.signmedia.ca/achieving-cost-effective-colour/