All you need to know about banners

Barricade banners

In the summer, many banners are installed on barricades at street fairs and other events. These are easy to make and a great way to dress up an outdoor area, but not everyone lays them out and prints them in both a cost-effective and attractive manner.

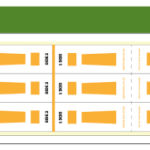

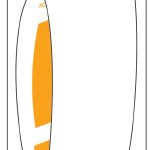

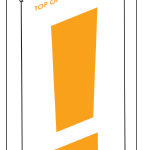

There are three general schools of thought on how to execute barricade banners:

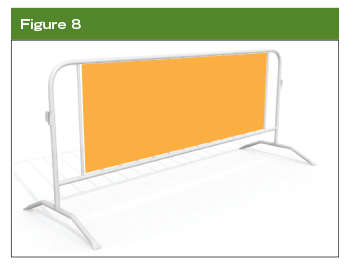

- Make a single-sided rectangular banner (see Figure 8). This is the cheapest option, but also the least attractive.

- Make a larger rectangular banner that drapes over the top of the barricade, with images printed from ‘head to head’ on both sides (see Figure 9). This is better, but not great.

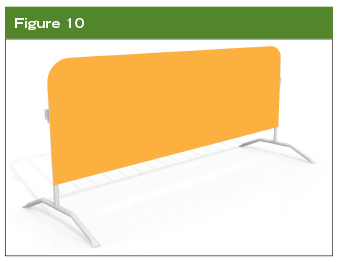

- Measure the barricade before printing two images head to head and finishing the top edge with a fitted curve (see Figure 10). This is the most presentable design. The file should be laid out with a couple of inches of bleed on either side. Finishing options include (a) grommets on the bottom corners for zip ties and/or (b) hook-and-loop (i.e. Velcro) straps below the top clasp and at the bottom edge.

Mitred pockets

In the past, large banners and billboards were installed on walls using flat bars, which were inserted into the material’s pockets and then fastened into drill holes in the wall. This was accomplished with a mitered pocket design, which allowed all four pockets to have open ends.

Today, the flat bar installation method is a thing of the past, but mitred pockets are still used. These are a better option whenever pockets are required on all four sides of a banner and open at both ends, so a bar or tube can be slid in from either end after the finishing stage, stretching the graphic over a frame of some sort.

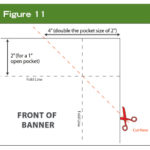

The following are the steps needed to create a mitred pocket:

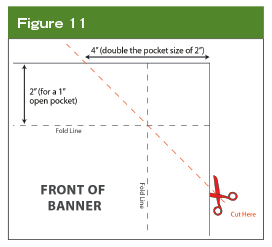

- Mark and cut the corners (see Figure 11).

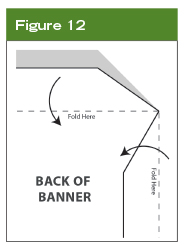

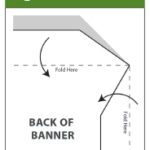

- Fold the edges over (see Figure 12).

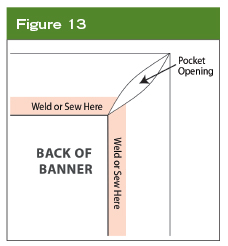

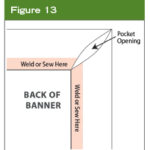

- Weld or sew the pocket, leaving the ends open (see Figure 13).

Hemming 101

Hemming is the act of folding over the edge of a material. There are several reasons to do so with a banner:

- To reinforce the edge of the banner, as folding creates a double layer, which is stronger than a single layer.

- To give the grommet something to hold. (Grommets are brass or silver rings that are punched through and pressed into the centre of the hem to allow a fastener, bungee cord, rope or wire tie to pass through the edge of the banner.)

- To keep the edge of the banner from curling in and out, particularly for suspended banners.

- To prevent the edge of a fabric banner from fraying or unravelling.

- To give the edge of a banner a more finished look.

There are also a few ways to make sure the hem remains folded during the useful life of the banner:

- Taping, using double-sided banner tape. This is the least expensive and least durable option.

- Sewing with a single or double stitch. This is the most common method for banner finishing. It looks good, lasts longer and does not cost much.

- Welding or heat sealing. This only works with certain materials, including banner PVC. The results look great, but this process usually carries the highest expense.