Sorry flex face, this project required the use of aluminum

The tower sign’s face is 5.5 m (18 ft) in height by 14.6 m (48 ft) in length, varying in size for each location, but generally considered huge for a sign. Typically, such a large surface would require a flex face (a tensioned flexible polyvinyl chloride [PVC] banner substrate that stretches across the face of the sign to create something that resembles the skin of a drum) with the Ikea logo printed on. This option was not feasible, however, due to the constant high winds that would reduce the sign’s longevity. Further, due to the sign’s size and height, the warranty of the flex face would not be honoured by the substrate’s manufacturer.

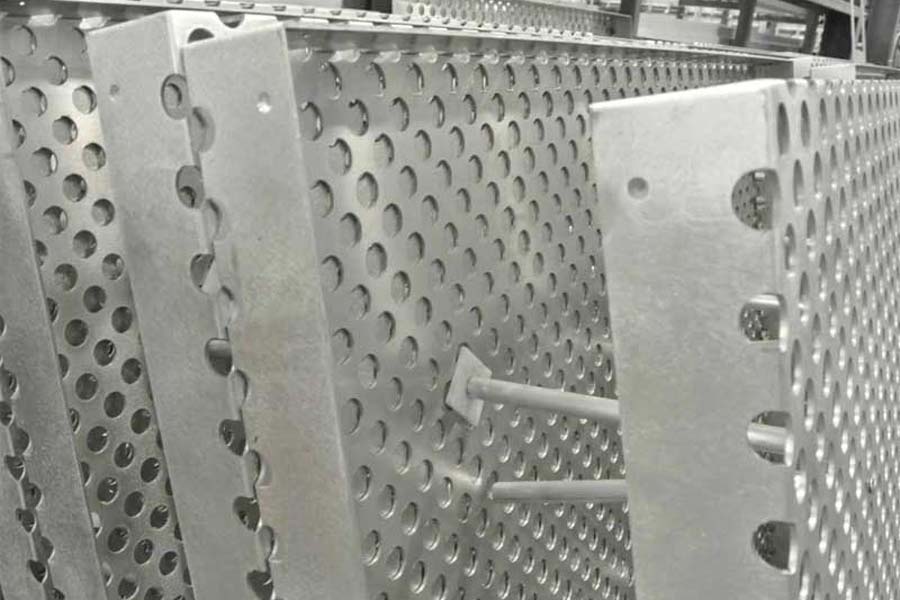

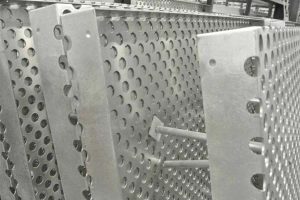

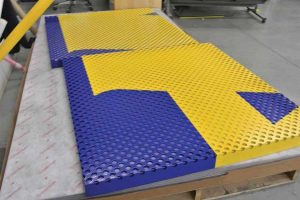

This is when the Montreal Neon Signs team came up with a creative plan by designing and fabricating perforated painted aluminum faces, each with an acrylic backing and applied 3M vinyl. This solution would honour all manufacturer warranties, benefit Ikea with a solid, durable sign and, most importantly, it would be resistant to high winds. The finished product has an appealing, clean look which is true to the Ikea brand. In fact, the client, engineers, and experts all agreed that using aluminum to manufacture the sign was the best choice to replace the flex face material for these particular installations.

Shipping and installing colossal signs

Transportation and installation are key stages in every sign installation project. If not planned and executed efficiently, there are risks of incurring high costs and delays. This is why the Ikea Winnipeg and Halifax tower sign projects required a knowledgeable team to co-ordinate these demanding jobs. Transporting and installing these signs was a challenge; however, the installation team was confident they would succeed.

The sign was designed and fabricated using perforated painted aluminum faces, each with an acrylic backing and applied 3M vinyl.

From the start, the crew from Montreal Neon Signs, who are accustomed to manufacturing and installing large scale projects such as these, were aware of the challenges that would come along with these colossal signs—not just designing and fabricating them, but also transporting each section, assembling them on site, and then erecting each sign.

When faced with projects like these, and to ensure they are completed successfully, Montreal Neon Signs focuses on planning and attention to detail. In fact, 3D video animations were developed and used to plan and test the step-by-step execution of each installation. This way the team could foresee and address all possible risks or even quickly adjust the plan, if necessary, during the installation. This meticulous preparation allowed crew members to execute both Ikea sign projects smoothly, with little to no divergence.