Assembling the Ikea Sign

by | 8 February 2019 3:12 pm

[1]

[1]To develop, fabricate, and install Ikea’s landmark signs, it required substantial engineering, research, and planning.

By Carlo Paolucci

In 2015, Ikea Canada went out for bid in search for a professional sign company that understood the importance of maintaining and standardizing their signage products. Montreal Neon Signs, Sign Media Canada’s 2018 Signmaker of the Year for the Quebec region, was invited to demonstrate its capabilities. Ikea was looking for more than a sign company; they wanted expertise in the areas of engineering, design, project management, and a company with extensive experience with light-emitting diode (LED) illumination. Essentially, the client was looking for a full-service sign company that understood the importance of brand specifications while offering reliable, durable, and cost-efficient products and services. Ultimately, they realized they not only required signage expertise, but also sign innovators, and Montreal Neon Signs, based in Laval, Que., was up for the challenge.

The navigation tower sign challenge

In unification with safe and reliable signage, Ikea’s requirements also entailed that all of their signs illuminated radiantly according to the company’s brand and colours. For this particular project, Montreal Neon Signs faced significant challenges in replacing a three-sided, flex-face navigation tower sign in Winnipeg and to manufacture and install a new navigation tower sign in Halifax.

[2]

[2]It was imperative for the sign to have a clean, minimalist appearance with a single-pole design.

To develop, fabricate, and install Ikea’s landmark signs, it required substantial engineering, research, and planning. This project was not simple by any means as Ikea wanted reassurance that the design of the navigation tower would meet all safety regulations, as well as be capable of withstanding high wind loads from all directions. In fact, calculations revealed wind speeds of 80 km/h (50 mph) and higher were frequent at the Ikea store locations; therefore, the signs had to include extended warranties. It was also imperative for the sign to have a clean, minimalist appearance with a single-pole design.

The navigation tower signs range from 27.4 to 42.6 m (90 to 140 ft) and higher. As a result, specialized equipment is required to perform any maintenance and/or repairs. That said, a maintenance and repair plan was developed that included the use of durable components and cost-effective servicing methods such as the design and placement of easily accessible power and LED units.

Another challenge the team confronted was conducting research to find the right substrates that not only offered extended durability, but would also meet Ikea’s specifications. The co-ordination and procurement of regulatory permits required professional negotiations and meticulous documentation, including an engineering seal of approval.

The transportation and installation of all necessary material, signs, and large equipment to the Ikea store required a separate dedicated team with years of logistics and installation experience. Further, the project carried a strict schedule and timeline had to be respected without any exceptions.

Sorry flex face, this project required the use of aluminum

[3]

[3]The navigation tower signs range from 27.4 to 42.6 m (90 to 140 ft) and higher.

The tower sign’s face is 5.5 m (18 ft) in height by 14.6 m (48 ft) in length, varying in size for each location, but generally considered huge for a sign. Typically, such a large surface would require a flex face (a tensioned flexible polyvinyl chloride [PVC] banner substrate that stretches across the face of the sign to create something that resembles the skin of a drum) with the Ikea logo printed on. This option was not feasible, however, due to the constant high winds that would reduce the sign’s longevity. Further, due to the sign’s size and height, the warranty of the flex face would not be honoured by the substrate’s manufacturer.

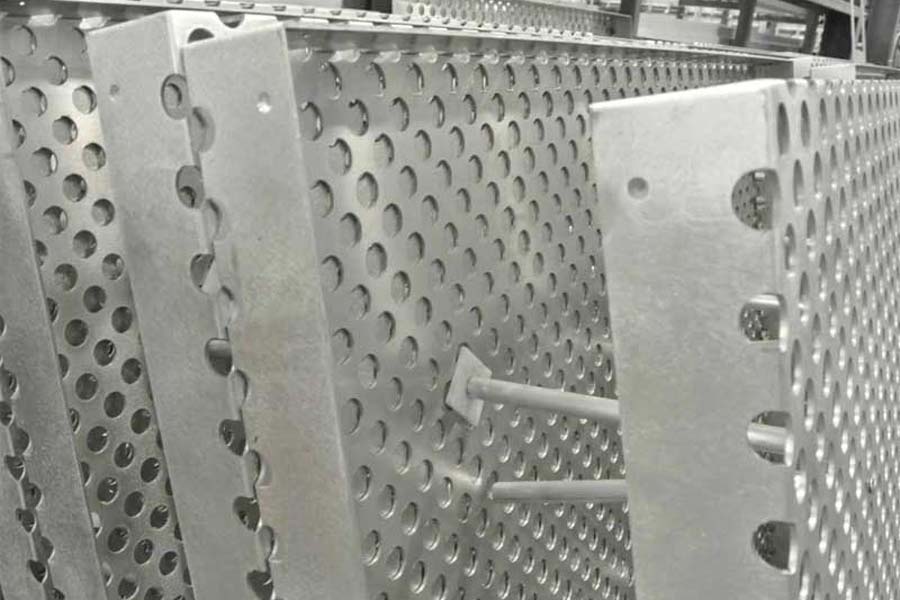

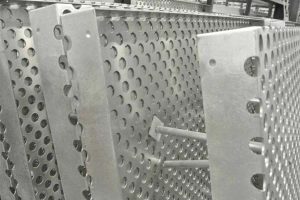

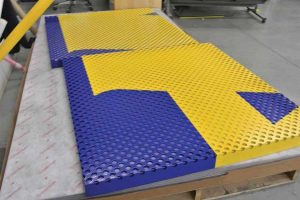

This is when the Montreal Neon Signs team came up with a creative plan by designing and fabricating perforated painted aluminum faces, each with an acrylic backing and applied 3M vinyl. This solution would honour all manufacturer warranties, benefit Ikea with a solid, durable sign and, most importantly, it would be resistant to high winds. The finished product has an appealing, clean look which is true to the Ikea brand. In fact, the client, engineers, and experts all agreed that using aluminum to manufacture the sign was the best choice to replace the flex face material for these particular installations.

Shipping and installing colossal signs

Transportation and installation are key stages in every sign installation project. If not planned and executed efficiently, there are risks of incurring high costs and delays. This is why the Ikea Winnipeg and Halifax tower sign projects required a knowledgeable team to co-ordinate these demanding jobs. Transporting and installing these signs was a challenge; however, the installation team was confident they would succeed.

[4]

[4]The sign was designed and fabricated using perforated painted aluminum faces, each with an acrylic backing and applied 3M vinyl.

From the start, the crew from Montreal Neon Signs, who are accustomed to manufacturing and installing large scale projects such as these, were aware of the challenges that would come along with these colossal signs—not just designing and fabricating them, but also transporting each section, assembling them on site, and then erecting each sign.

When faced with projects like these, and to ensure they are completed successfully, Montreal Neon Signs focuses on planning and attention to detail. In fact, 3D video animations were developed and used to plan and test the step-by-step execution of each installation. This way the team could foresee and address all possible risks or even quickly adjust the plan, if necessary, during the installation. This meticulous preparation allowed crew members to execute both Ikea sign projects smoothly, with little to no divergence.

[5]

[5]Montreal Neon Signs developed 3D video animations to plan and test the step-by-step execution of each installation.

Knowing that allocating more time during the planning phase will result in faster manufacturing and installation processes—with reduced risk of errors—Montreal Neon Signs invests heavily in researching and planning each project to the fullest. For example, to anticipate all possible obstacles and risk factors when unloading the Ikea signs, 3D video animations were used to demonstrate to the team how the delivery and unloading of the signs were to be performed. They also helped to visualize where the material, signs, and equipment should be located on site. In doing this, it eliminated any confusion during the delivery and increased productivity as everyone knew what to do and where to go.

The plans also reassured the client that all perimeters were well-established and adequately secured for its customers visiting the store. In this case, the video helped the team determine the space required on-site, and the manoeuvers needed to manipulate the crates and signs in the busy Ikea parking lots. After its route from Montreal to Halifax, the signs were unloaded and assembled on-site. Large cranes were

in place to assist with the assembly and installation of the signs. Depending on the number of signs being installed at each site, it took approximately one to two weeks to complete the project. On the Halifax project, for example, the team completed the installation in one week and everything went as planned.

An all-around success

The Montreal Neon Signs team completed the Halifax project on time and on budget. City officials and regulators were satisfied with the result, and most importantly, Ikea was pleased with the finished project.

In fact, the client was so impressed they decided to use this project as the standard specification for all its navigation tower signs. As a result, Montreal Neon Signs successfully completed the rebrand of all Ikea stores across Canada to ensure the same high-quality signage standard was followed at all of its locations.

Montreal Neon Signs team of project managers, led by Sonya Robert, were dedicated solely on the Ikea program to ensure the successful completion for each site. To date, the Ikea program is one of Montreal Neons’ most accomplished programs the signmaker has completed in such a short time frame. The company continues to manufacture and install Ikea signs across Canada.

Carlo Paolucci is president of Montreal Neon Signs. For more information, visit www.montrealneon.com[6].

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/02/DJI_0031-CLEAN.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/02/20170905_113837.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/02/DJI_0038.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/02/Ikea_MNeon_shop_04.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/02/20170919_060231.jpg

- www.montrealneon.com: http://www.montrealneon.com/

Source URL: https://www.signmedia.ca/assembling-the-ikea-sign/