Benefiting from trends in lamination

Specialty finishes

Another option is to branch out into non-traditional or ‘specialty’ overlamination films to create a unique signature look for custom graphics. Taking the time to understand each customer’s needs will help determine the most appropriate surface finish. Gone are the days of simply using whatever lamination films are sitting on the shelf.

Traditional finishes include gloss, lustre and matte. Non-traditional varieties range from dry-erase and anti-graffiti films to anti-slip and scratch-resistant pebble finishes. Specialty products include canvas, linen, leather, three-dimensional (3-D) holographic, food-contact-approved and biodegradable films.

By offering a wider variety of finishes, a sign shop can satisfy its customers with a wider variety of jobs, which will help create a longer-term income stream and higher profits.

UV-cured graphics

Ultraviolet-curing (UV-curing) inkjet printers have made their way into signs shops over the years. Their popularity is driven in part by the ease of direct-to-board printing.

There is nevertheless a need for special lamination films for UV-cured output, to provide greater protection against the elements and to enhance the printed graphics. Although better and better UV-cured inks continue to be developed, they still encounter difficulty with low-surface-energy substrates like styrene, so lamination is helpful as a scratch guard and to help seal the inks more permanently to the surface. Additionally, most UV-cured inks have a relatively dull appearance, so lamination is often needed to ensure a glossier look.

Signmakers will need to consult with their suppliers, as the special laminates that are compatible with UV-cured inks are not yet widely available.

Window graphics

Window films continue to represent a growth opportunity for signage, as well, fuelled in part by customers’ desire to find more real estate for their display graphics. This trend is especially noticeable in retail environments. While grocery stores have long used their glass windows as an effective area for visual marketing, today many other ‘genres’ of stores are also using their windows for advertising purposes.

With the growth of such demand, a wider variety of printable films and mounting adhesives have been specifically designed for application onto glass. To choose between these, it is important to consider the characteristics of the customer’s graphics and where they are to be applied.

Local regulations and codes, for example, may dictate whether the graphics are mounted to the inside or outside surface of the windows. The choice between wet- and dry-application films may rest on whether graphics professionals or local store employees will be installing them.

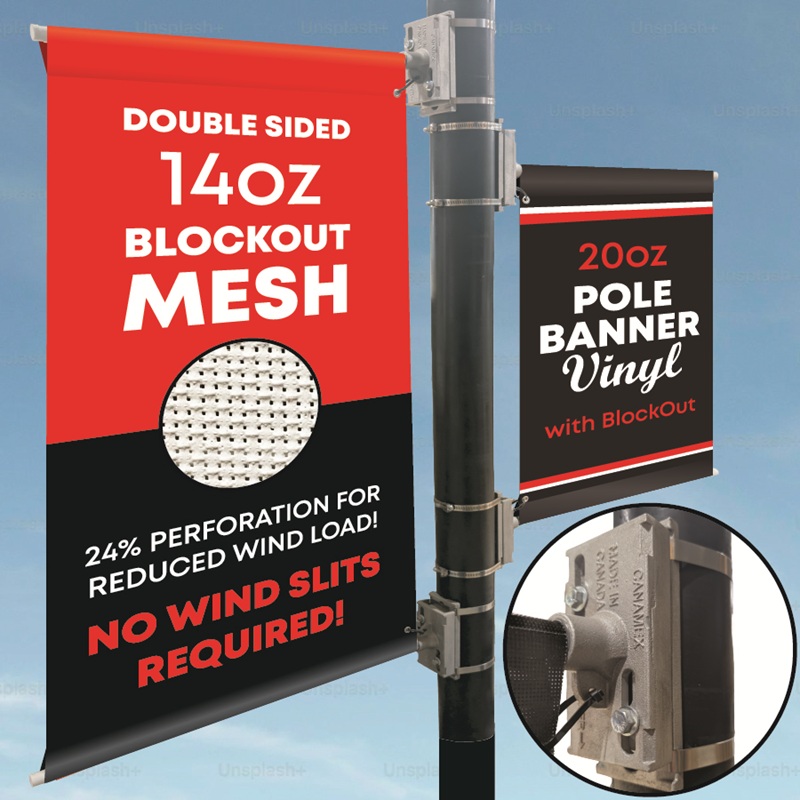

Further, the films may be clear or opaque, perforated or non-perforated, with single- or double-sided graphics, depending on whether or not the retailer wants customers and staff to be able to see through them from inside the store. And based how long the graphics need to last, the materials may be repositionable or ‘permanent.’

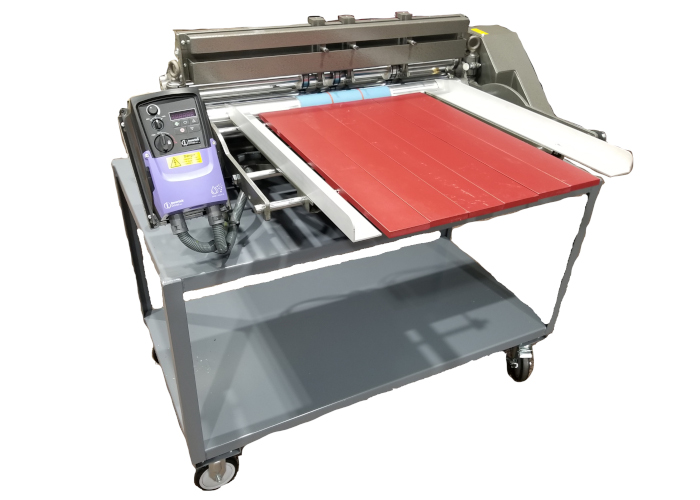

Beyond the media, another option to consider is a double-sided mounting adhesive formulated specifically for use on glass. For this type of job, the adhesive and the printable film are separate, so the customer can first choose his/her preferred substrate. Then, the printed graphics can be mounted to the ‘permanent’ side of the adhesive using a laminator. The resulting piece is taken to the job site and installed on its repositionable side. Many of these adhesives today include special air channels on this side to ensure bubble-free results when applied by hand onto dry glass.

Liquid lamination

Beyond film-based laminates and adhesives, liquid lamination is one of the latest trends to make waves in the sign industry. Most liquid laminates are available in gloss, lustre or matte finishes and are compatible with solvent-based inkjet-printed output, while newer UV-cured inks and durable aqueous ‘latex’ inks need special formulations.

There are also liquid laminates manufactured for specific types of graphic applications. Car wrap liquids, for example, are designed with maximum flexibility and UV resistance in mind, while wall décor liquids are formulated with moisture- and mildew-resistant additives. Liquid coatings for fine-art reproductions are produced with extra flexibility to help prevent edge cracking.