Illumination: Best practices for LED layout designs

The following is a summary of the workflow for a typical job in those early days of the LED-illuminated signage market:

- A retail business is about to open and needs channel letters for its storefront sign. The owner identifies a number of local electrical sign manufacturers and sends out a request for quotation (RFQ).

- Each of the local shops designs a sign with the requested copy in the specified letter sizes. Then, each shop sends its design—along with specifications for channel letter depth, face material and other factors—to its trusted sign products distributor to get a quote on LEDs, power supplies and any other materials required to fabricate the sign.

- Each sign products distributor provides an estimate for all of the materials needed to fulfil the job, except for the actual LED layout, associated module count and power supplies. For these details, the dealer forwards the design file to its own LED supplier or one specified by the sign shop.

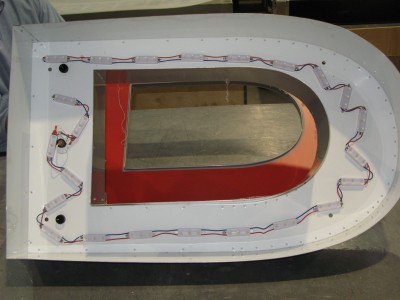

- The LED manufacturer/supplier designs the layout according to its own specifications for module density, based on sign can depth, stroke width and other considerations. This layout is combined with the bill of materials and sent back to the sign products distributor.

- The sign products distributor studies the layout and provides a full estimate for the sign shop.

- The sign shop puts all of the details together and presents the layout and estimate to the retail business owner.

- The retail business owner chooses from among the bids and orders the sign.

Given all of the steps in this process, it may well take several weeks, rather than just a few days, for the retail business owner to receive a few bids to evaluate.

Today’s market

As mentioned, more signmakers today are recognizing the benefits of creating their own LED layouts in-house. Further, the sign supply channel has in some cases effectively acted as a middleman between sign shops and LED manufacturers by also creating layouts for customers.

There are a number of compelling reasons for sign shops to handle LED layouts in-house:

Faster response time

Sign buyers have come to expect fast response times, but LED manufacturers and suppliers may be inundated with layout requests at any given moment, limiting their ability to get back to sign shops quickly. During the waiting period of at least several days, a competitor could be getting a head start, creating layouts in minutes instead. Indeed, by the time one sign shop’s estimate gets in front of its customer, it could well be third or fourth in line instead of first—or the job could already be lost to a competitor.

Control over entire job workflow

Another primary benefit of keeping the design and layout process in-house is to maintain control over the entire workflow for a given job. This is not to say signmakers need to be control freaks, but there are advantages for practical design, estimating and production reasons. Any part of a workflow that falls outside a shop’s control may be prone to changes and/or delays. If changes are required, it is obviously better to make those changes directly within the shop, rather than getting back in line for an LED supplier’s feedback.