Illumination: Best practices for LED layout designs

Better knowledge of each job

When a sign designer creates an LED layout in-house, he/she inherently has more detailed knowledge about that design and can address direct questions from the production floor and/or the client, such as about why certain decisions were made about the types of modules, the number of power supplies, the wiring method, the number of runs in each stroke, the linear density of modules on each run, etc.

It is never a good idea to be in front of the customer and not be able to answer such basic questions. And if the customer ends up asking for a simple change, it should not take days to complete.

More choice for customers

Further, when a sign shop handles LED layouts in-house, it becomes much easier to present a variety of options to the customer in a consistent format. These layout options might include the least expensive, the brightest and/or the simplest with the lowest number of modules and power supplies, all in a format that allows the customer to compare ‘apples to apples.’

If a sign shop were to send out a layout design job to three different LED manufacturers for three estimates, on the other hand, they are likely to present three different formats, with the risk of confusing customers instead of informing them.

Design software

In the early stages of the LED-based signage market, there was no specific software for laying out LED modules, but both sign design software and ‘generic’ design software were used to some degree, including Corel Draw, Adobe Illustrator and AutoCAD. These systems made sense because they were already being commonly used in electrical sign shops for other purposes, but they lacked specific capabilities for LED module layouts.

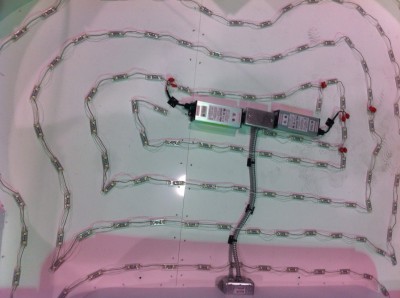

The most important aspect of such a layout is the positioning of each individual module. The more automated this process can become, the better for sign shops. With generic software, it is possible to (a) position the modules individually or along a simple inline or (b) set up a grid system and position modules at each of the grid’s intersecting points.

Another variation of the second approach is to determine the area of a channel letter and then identify the number of LED modules needed to cover that area, e.g. 100 modules per square metre. None of these approaches is very accurate, however, except in the very simplest cases.