Illumination: Best practices for LED layout designs

by all | 28 July 2013 8:30 am

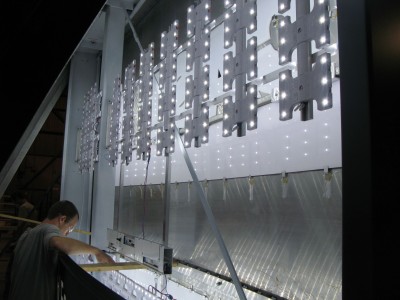

[1]

[1]Photos courtesy Teksign

By Jeff Fassett

While light-emitting diodes (LEDs) have taken over channel letter applications that were previously illuminated with neon, sign shops still face challenges in designing complete LED layouts inside the letters for optimized esthetics. After all, sign fabricators had decades to establish best practices for neon, while LEDs are still relatively new to the industry.

One of the ways LED suppliers helped usher the immature technology to industry acceptance was by designing layouts for their customers. That may have been necessary in the earliest days of LED-illuminated channel letters, but although this practice has endured, many signmakers are now realizing they can better control their projects and be ‘faster to market’ if they use design software to come up with their own layouts in-house.

Transition from neon to LEDs

When LEDs first arrived on the sign industry ‘scene’ for use in channel letters and sign cabinets, there was a significant backlash against the technology. Both neon and fluorescent lighting had been used successfully for many years, with well-established sign design techniques to achieve optimal brightness levels, as well as standardization across suppliers that made it easy for sign shops to switch brands and not have to start from scratch. There was an especially large group of professionals in the sign industry who were trained and highly experienced in the art of neon signage.

[2]

[2]As signmakers have tested different methods, ‘best practices’ have emerged for designing LED layouts.

When LED technology was new to the sign industry, suddenly everything was different. Each supplier made different claims about such attributes as brightness, power consumption, colour temperature, longevity, etc. As a result, each system of LEDs had to be laid out differently, in terms of the number and position of modules, to achieve a favourable result in comparison to neon or fluorescent illumination. And there were already many more suppliers of LEDs than of neon or fluorescent lamps.

Sign shop employees were eager to try the new technology, but did not yet have the right knowledge or tools to design optimal layouts, so the suppliers stepped in and offered to handle layouts for them at no cost.

While this tactic was certainly a practical way to encourage the adoption of LEDs, it did nothing to educate signmakers. Instead, it created a sort of ‘black box’ situation, where sign shops would send design files to the supplier and then get a result back, as though LEDs layouts were inherently complex and mysterious and could not be revealed to their users. Even minor changes had to be sent back through the process again, since signmakers did not themselves have any means to change layouts directly.

So, while this process was technically free for the sign shops, it did entail costs in terms of slower response times to customers, limited flexibility in making changes and, of course, a lack of knowledge about the particulars of each job.

The following is a summary of the workflow for a typical job in those early days of the LED-illuminated signage market:

- A retail business is about to open and needs channel letters for its storefront sign. The owner identifies a number of local electrical sign manufacturers and sends out a request for quotation (RFQ).

- Each of the local shops designs a sign with the requested copy in the specified letter sizes. Then, each shop sends its design—along with specifications for channel letter depth, face material and other factors—to its trusted sign products distributor to get a quote on LEDs, power supplies and any other materials required to fabricate the sign.

- Each sign products distributor provides an estimate for all of the materials needed to fulfil the job, except for the actual LED layout, associated module count and power supplies. For these details, the dealer forwards the design file to its own LED supplier or one specified by the sign shop.

- The LED manufacturer/supplier designs the layout according to its own specifications for module density, based on sign can depth, stroke width and other considerations. This layout is combined with the bill of materials and sent back to the sign products distributor.

- The sign products distributor studies the layout and provides a full estimate for the sign shop.

- The sign shop puts all of the details together and presents the layout and estimate to the retail business owner.

- The retail business owner chooses from among the bids and orders the sign.

Given all of the steps in this process, it may well take several weeks, rather than just a few days, for the retail business owner to receive a few bids to evaluate.

Today’s market

As mentioned, more signmakers today are recognizing the benefits of creating their own LED layouts in-house. Further, the sign supply channel has in some cases effectively acted as a middleman between sign shops and LED manufacturers by also creating layouts for customers.

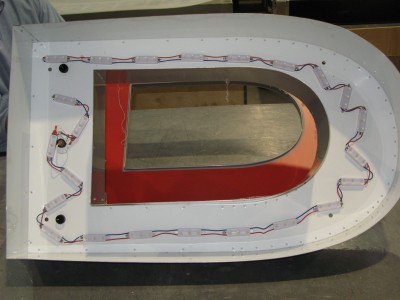

[3]

[3]In this letter, some of the modules have been rotated slightly, so as to fit more LEDs along the sides.

There are a number of compelling reasons for sign shops to handle LED layouts in-house:

Faster response time

Sign buyers have come to expect fast response times, but LED manufacturers and suppliers may be inundated with layout requests at any given moment, limiting their ability to get back to sign shops quickly. During the waiting period of at least several days, a competitor could be getting a head start, creating layouts in minutes instead. Indeed, by the time one sign shop’s estimate gets in front of its customer, it could well be third or fourth in line instead of first—or the job could already be lost to a competitor.

Control over entire job workflow

Another primary benefit of keeping the design and layout process in-house is to maintain control over the entire workflow for a given job. This is not to say signmakers need to be control freaks, but there are advantages for practical design, estimating and production reasons. Any part of a workflow that falls outside a shop’s control may be prone to changes and/or delays. If changes are required, it is obviously better to make those changes directly within the shop, rather than getting back in line for an LED supplier’s feedback.

Better knowledge of each job

When a sign designer creates an LED layout in-house, he/she inherently has more detailed knowledge about that design and can address direct questions from the production floor and/or the client, such as about why certain decisions were made about the types of modules, the number of power supplies, the wiring method, the number of runs in each stroke, the linear density of modules on each run, etc.

It is never a good idea to be in front of the customer and not be able to answer such basic questions. And if the customer ends up asking for a simple change, it should not take days to complete.

More choice for customers

Further, when a sign shop handles LED layouts in-house, it becomes much easier to present a variety of options to the customer in a consistent format. These layout options might include the least expensive, the brightest and/or the simplest with the lowest number of modules and power supplies, all in a format that allows the customer to compare ‘apples to apples.’

If a sign shop were to send out a layout design job to three different LED manufacturers for three estimates, on the other hand, they are likely to present three different formats, with the risk of confusing customers instead of informing them.

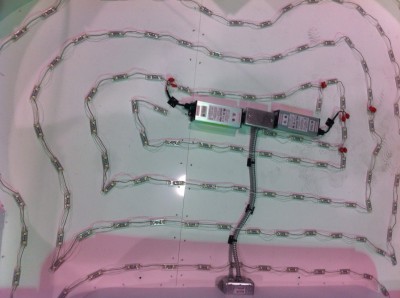

[4]

[4]One of the industry’s default options has been to lay out LEDs in concentric inlines, each with proper run-gap spacing. Photos courtesy Esco

Design software

In the early stages of the LED-based signage market, there was no specific software for laying out LED modules, but both sign design software and ‘generic’ design software were used to some degree, including Corel Draw, Adobe Illustrator and AutoCAD. These systems made sense because they were already being commonly used in electrical sign shops for other purposes, but they lacked specific capabilities for LED module layouts.

The most important aspect of such a layout is the positioning of each individual module. The more automated this process can become, the better for sign shops. With generic software, it is possible to (a) position the modules individually or along a simple inline or (b) set up a grid system and position modules at each of the grid’s intersecting points.

Another variation of the second approach is to determine the area of a channel letter and then identify the number of LED modules needed to cover that area, e.g. 100 modules per square metre. None of these approaches is very accurate, however, except in the very simplest cases.

Using generic software, when modules need to be repositioned to achieve optimal, uniform illumination—or added to or removed from the layout—it is a manual, individual task. Each module needs to be moved, added or removed before other modules are adjusted to maintain proper spacing. There is no way to select multiple modules at the same time.

Similarly, generic design software can be used to import a power supply as an ‘object’ and position it in the layout, with a rectangular or polygonal selection of modules connected to it. This involves manually counting all of the modules to include with that power supply, however, as well as adding the wattages of each module to ensure they do not exceed the supply’s capacity. This can be time-consuming and error-prone, especially when planning large channel letters and/or sign cabinets.

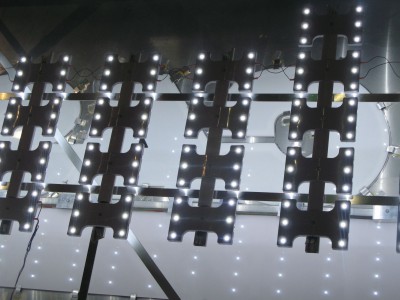

[5]

[5]For very large sign cabinets, another option has been to lay out straight parallel lines of LED modules in a vertical or horizontal orientation. Photo courtesy Teksign

For these and other reasons, generic design software is only a limited option for laying out LED designs. Sign-specific design and layout tools, on the other hand, are a logical choice. They can create vector paths for LEDs, each evenly populated with modules, with a priority placed on the corners.

As LED-based signage has become more popular, the industry has seen the emergence of LED-specific sign design software, with new tools that streamline the process for creating complete LED layouts, including modules and power supplies. Automatic layout routines and editing tools support a wide range of channel letter fonts and sizes.

Winning in the market

As more channel letters and sign cabinets are lit with LEDs, rather than with traditional neon or fluorescent technology, it is safe to say they have largely ‘won’ in the market. So, while the process of generating layouts of LEDs necessarily started out with their suppliers, it only makes sense that electrical sign companies have brought these tasks in-house over time, for reasons of control and quick turnaround.

Jeff Fassett is president of Aries Graphics International, which develops design software for the sign industry. For more information, visit www.aries-graphics.com[6].

To read the whole article, click here[7].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/IMG_1507.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/IMG_1500.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/IMG_1494.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/photo-1.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/IMG_1477.jpg

- www.aries-graphics.com: http://www.aries-graphics.com

- here: http://www.kenilworth.com/publications/smc/de/201307/files/58.html

Source URL: https://www.signmedia.ca/best-practices-for-led-layout-designs/