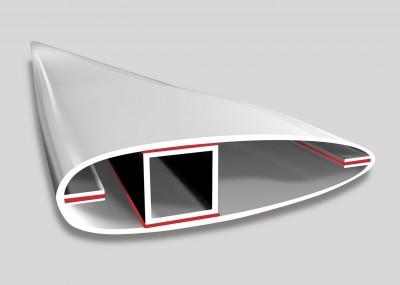

Joining two aluminum extrusions, adhesives provide an alternative to welding or drilling, with no weakening of the metal.

Configuring joints and lines

Given the realities of sign design and construction, joint configurations cannot usually be changed to accommodate a particular adhesive, so instead, the adhesive needs to be appropriate for the existing sign design.

Minimum bond line thicknesses will disqualify a number of types of adhesive products. Another important factor is the type of joint, whether it is tensile, shear or peel, and whether the substrates are flanged or configured as a butt joint, in which case adhesive strength becomes a key factor. For the most part, different adhesives perform very differently depending on the nature of the stresses placed on them.

Since there is no need with adhesives to make accommodations for fasteners, sign design lines can be kept smooth and clean. Hence, bonding helps free designers to more fully explore their imaginations.

Boosting durability

When specifying a sign for durability requirements, there is a temptation to begin by focusing on bond strength. In reality, structural adhesives are generally far stronger than they need to be, so strength may not be an issue at all, depending on the particular application.

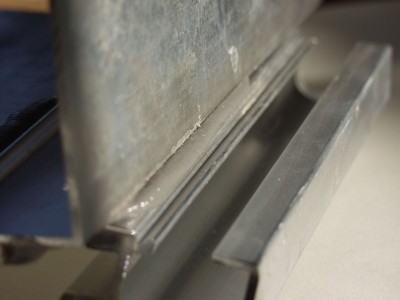

Another important advantage is the fundamental way chemical bonding reduces stress on the elements of a sign. Mechanical fixation can require the drilling of holes, the insertion of clips or the high heat levels associated with welding, all of which will weaken the underlying material and then concentrate stress at the newly created weak spot.

Signmakers are all too familiar with materials cracking or breaking at their fastening points. Bolts and screws tend to work themselves loose over time, while spot welds are prone to metal fatigue, discolouration and dimpling.

Exposed outdoor signs must endure the cumulative effects of relentless environmental elements, including thermal cycling, wind gusts, ultraviolet (UV) radiation, water and salt. These forces are a threat to a sign’s structural integrity and visual appearance.

Moisture leaks can cause serious problems for metal components and electrical sign installations, particularly through holes and block seams left when mechanical fasteners are used. The right adhesive, on the other hand, can achieve a complete seal without the need to punch holes through the sign materials in the first place.

The same property that provides the sealing action—i.e. the polymer adhesive bridging the substrate materials both chemically and mechanically—also helps to absorb and internalize the stresses caused by expansion, contraction and deflection. At the same time, the adhesive distributes the remaining forces more equally, meaning there is far less chance of breaking.

Mechanical fixations cannot do this. Instead, they produce stress points that do not take advantage of the entire system, disassociating a sign’s structural elements, such that each individual part functions more or less separately from the others. Only a limited degree of stress can be shared through mechanical fasteners by leverage or tension.

In fact, shifting from point loads to a full-perimeter bond can turn a substrate panel into a fully functioning stress member.

Ensuring integrity

Today’s engineered adhesive products can accomplish many objectives in signmaking. A single-step bonding system not only simplifies the manufacturing process, but also helps overcome design challenges and increases durability, resulting in a fully sealed sign with cleaner lines. So long as the right adhesives are chosen, they will become an integral part of a sign shop’s work procedures.

Montreal-based Krys Wesselink is the Canadian sales manager for ITW Plexus, which manufactures adhesives. For more information, visit www.itwplexus.com.