When using an aerial lift platform or crane above pedestrian walkways, an extra team member should be on hand to direct traffic and be a spotter for any hazards.

Jobsite risk evaluation

Every jobsite has its own set of challenges; therefore, it is important to identify them well in advance of arriving on site. Whether an aerial platform or crane is being used one must examine the worksite closely to detect any potential hazards, including:

Overhead wires or high tension powerlines

Installers must make sure they are within a safe distance from powerlines. If a job is too close to these wires it is imperative the local electrical service provider is contacted to perform a site visit, examine the situation, and come up with a plan to either isolate the power and ground the lines, or cover the lines with an insulated cover. The power company will need plenty of notice to make this happen and the customer will need to be notified for any extra costs they may incur.

High traffic areas in the work zone walkways for pedestrians

Using an aerial lift platform or crane in a high traffic area or above pedestrian walkways is a daily occurrence for many sign installers. In these cases, an extra team member should be on hand to direct traffic, answer questions from pedestrians, and be a spotter for any hazards that may incur. Further, temporary signs for pedestrians with clear instructions on which pathway they should use to safely pass around the jobsite should also be employed. Creating clear pathways can also be accomplished by using caution tape, pylons, and barriers.

Rigging and lifting hand signals

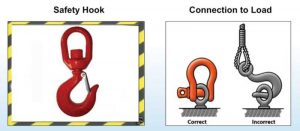

When it comes to lifting signs into place, the installation crew will need to know a few basic rules. Proper rigging is the first step to a safe sign installation when lifting with a crane or boom truck. First, one needs to examine the lift points. It does not matter if the project involves lifting a new build or an existing sign structure, an operator should never rely on another person’s word that the lift point is secure. Make sure that where you are attaching your lifting strap is safe and secure. Make sure your lifting straps are on a horizontal sling angle of at least 60 degrees, the less the degree the more inward crushing force there will be on your lifting points.

When lifting a load you almost always need a tag line to control your load as it is lifted into place. You will need to examine the load for a proper anchor point to attach your tag line, although your tag line anchor point won’t undergo nearly as much lifting force as your main lift point it still needs to be strong enough to control the weight of your load especially if wind is involved. Lastly make sure your crew is very familiar with crane hand signals, having a spotter and a person to direct the crane operator is extremely important.

Proper rigging is the first step to a safe sign installation when lifting with a crane or boom truck.

Crane loads, wind, and outriggers

There are many sizes of boom trucks sign professionals use and all of them have their own set of load limits, set-up requirements, safety sensors, and outriggers. Therefore, it is important one knows what their boom truck can handle and how to set it up properly to safely complete the task at hand. That said, there is a load and platform operating chart located in the boom truck’s manual. This information is also typically located near the controls (lower and upper). Sign installers should examine these closely before operating the boom.

Operators will find as the boom is extended and lowered the maximum allowed load will greatly decrease. Therefore, before one lifts any signage, it is important to go over the max distances for both height and radius to make sure they are operating within the safe zones of the load chart.