Boom Truck Operation: Best practices for using heavy equipment to install signs

by | 28 April 2020 2:46 pm

[1]

[1]It is a good idea for the installation team to discuss the project in length whereby answering the questions mentioned above and filling out the traffic plan before submitting it to the required municipality in which they will be working.

By Mark Wallis

When a sign professional is tasked with a project that has them working near or on a roadway it is imperative for them to explore all risks involved in completing the project. There are some extremely important questions sign installers must ask themselves before even arriving on-site. These include:

- Where to park?

- Where is the operating/lifting radius?

- Where is the work zone?

- How will traffic be directed away from the hazard zones?

- What signs will be needed to direct traffic?

- Are barriers, caution tape, and scaffolding needed?

- How long will they be on-site?

- Whose business/right of way will be affected by operating on-site and are they okay with the plan?

- What risks are involved?

[2]

[2]Installers must make sure they are within a safe distance from powerlines.

Laws of the road

In Ontario, for example, when working near or on a roadway, sign installers need to follow the Ontario Traffic Manual book 7. This book contains a multitude of temporary traffic plans for any type of lane/road closure one may need to perform to complete the task at hand.

That said, it is a good idea for the installation team to discuss the project in length whereby answering the questions mentioned above and filling out the traffic plan before submitting it to the required municipality in which they will be working. It is important to complete this work far in advance of the scheduled installation as this will allow any necessary changes to be completed in a timely manner.

Submitting these traffic plans is extremely important—not only for the safety of the sign installation team, but also for pedestrians. It provides the municipality the opportunity to notify emergency response personnel about any road and/or lane closures, too.

[3]

[3]When using an aerial lift platform or crane above pedestrian walkways, an extra team member should be on hand to direct traffic and be a spotter for any hazards.

Jobsite risk evaluation

Every jobsite has its own set of challenges; therefore, it is important to identify them well in advance of arriving on site. Whether an aerial platform or crane is being used one must examine the worksite closely to detect any potential hazards, including:

Overhead wires or high tension powerlines

Installers must make sure they are within a safe distance from powerlines. If a job is too close to these wires it is imperative the local electrical service provider is contacted to perform a site visit, examine the situation, and come up with a plan to either isolate the power and ground the lines, or cover the lines with an insulated cover. The power company will need plenty of notice to make this happen and the customer will need to be notified for any extra costs they may incur.

High traffic areas in the work zone walkways for pedestrians

Using an aerial lift platform or crane in a high traffic area or above pedestrian walkways is a daily occurrence for many sign installers. In these cases, an extra team member should be on hand to direct traffic, answer questions from pedestrians, and be a spotter for any hazards that may incur. Further, temporary signs for pedestrians with clear instructions on which pathway they should use to safely pass around the jobsite should also be employed. Creating clear pathways can also be accomplished by using caution tape, pylons, and barriers.

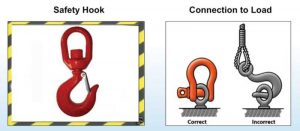

Rigging and lifting hand signals

When it comes to lifting signs into place, the installation crew will need to know a few basic rules. Proper rigging is the first step to a safe sign installation when lifting with a crane or boom truck. First, one needs to examine the lift points. It does not matter if the project involves lifting a new build or an existing sign structure, an operator should never rely on another person’s word that the lift point is secure. Make sure that where you are attaching your lifting strap is safe and secure. Make sure your lifting straps are on a horizontal sling angle of at least 60 degrees, the less the degree the more inward crushing force there will be on your lifting points.

When lifting a load you almost always need a tag line to control your load as it is lifted into place. You will need to examine the load for a proper anchor point to attach your tag line, although your tag line anchor point won’t undergo nearly as much lifting force as your main lift point it still needs to be strong enough to control the weight of your load especially if wind is involved. Lastly make sure your crew is very familiar with crane hand signals, having a spotter and a person to direct the crane operator is extremely important.

[4]

[4]Proper rigging is the first step to a safe sign installation when lifting with a crane or boom truck.

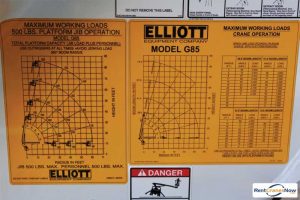

Crane loads, wind, and outriggers

There are many sizes of boom trucks sign professionals use and all of them have their own set of load limits, set-up requirements, safety sensors, and outriggers. Therefore, it is important one knows what their boom truck can handle and how to set it up properly to safely complete the task at hand. That said, there is a load and platform operating chart located in the boom truck’s manual. This information is also typically located near the controls (lower and upper). Sign installers should examine these closely before operating the boom.

Operators will find as the boom is extended and lowered the maximum allowed load will greatly decrease. Therefore, before one lifts any signage, it is important to go over the max distances for both height and radius to make sure they are operating within the safe zones of the load chart.

[5]

[5]Operators will find as the boom is extended and lowered, the maximum allowed load will greatly decrease. Before lifting any signage, it is important one goes over the max distances for both height and radius to make sure they are operating within the safe zones of the load chart.

Weather can also play a huge factor when lifting a load; one should never operate a boom truck during wind speeds greater than 11 m/s (36 fps). The load charts attached to the equipment are calculated without wind load. When taking wind speed into consideration, it can easily double the weight of the load. Another weather-related consideration is rain as it can not only make things slippery, but can also collect in certain areas of the load. In this regard, a sign installer will need to pay close attention to this as it can increase the weight of the load.

Cold weather installs are another factor in Canada, especially in the western regions where temperatures can drop below -40 C (-40 F). In these frigid temperatures, plastics and metals are very brittle, and hydraulic fluid becomes very thick. As a result, boom trucks are slower to operate and the motors need to work extra hard to pump the oil through the hydraulic systems. Further, cold weather puts a lot of pressure on fittings and hoses, so it is important for operators to make sure they are in good working order and not cracked or damaged. Adding heaters to the truck’s oil pan can help greatly in terms of the motor’s longevity as it will not have to work as hard to pump oil through the lines.

Lightening is another huge factor when it comes to operating a boom truck. In case, one must make sure they are always on top of the current weather conditions. If there is any chance for lightning to occur it is always a safe bet to reschedule the job. The crew’s safety is paramount. In some cases, it is unpredictable when this type of weather may occur; however, should an operator see lightening, they should have an emergency plan in place to vacate the vehicles and get to safe cover where the crew can wait the storm out.

Climate also plays a factor when the truck is going to be parked for the duration of the job—be it snow, rain, or heat. Therefore, a sign installer needs to know how to properly plan for the jobsite based on the forecasted conditions.

Ground safety

A lot of times one will be required to drive on grass, dirt, or soft ground to reach the area where the sign is being installed. In these cases, the operator should test the ground before driving on it. A good way a sign installer or truck operator can do this is by digging one’s heal into the ground to see if it is solid. Another failsafe is to ask the landlord or client if other vehicles have recently driven on the property.

[6]

[6]A lot of times one will be required to drive on grass, dirt, or soft ground to reach the area where the sign is being installed. In these cases, the operator should test the ground before driving on it.

If the ground is too soft, or if one is simply unsure, it is a good idea to have a few sheets of 19-mm (0.75-in.) plywood on hand to lie down to create a pathway for the truck to drive on. It is also good practice to park on the plywood when the truck will be idle for most of the day as a way to prevent it from sinking into the ground.

Concrete sidewalks or roadways are not always rated for boom trucks to drive on. If one has to drive on a concrete access point to reach a jobsite, it is important to know the rating of the concrete. If a concrete access point is mainly intended for foot traffic it is likely it was not designed to provide passage for boom trucks. Driving onto this type of concrete could potentially crack or damage the pathway. Should this occur, it will result in costly charges being billed back to the sign company. Therefore, asking the right questions beforehand will help alleviate any unnecessary stress.

Mark Wallis is one of the owners of Signature Sign & Image in Niagara Falls, Ont. He is also the director of safety and installations for the Young Professionals Network (YPN). Wallis can be contacted via email at mark@signaturesigns.ca[7]. For more information on the YPN, follow the group on Instagram @ypncanada.

- [Image]: https://www.signmedia.ca/wp-content/uploads/2020/04/Traffic-Control-King-St.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2020/04/Redeemer-Church-Crane.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2020/04/20190619_125059.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2020/04/rigging.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2020/04/Elliott-Load-Chart.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2020/04/20200122_165700.jpg

- mark@signaturesigns.ca: mailto:mark@signaturesigns.ca

Source URL: https://www.signmedia.ca/boom-truck-operation-best-practices-for-using-heavy-equipment-to-install-signs/