SMC: How large is the facility?

MP: We currently have 14 full-time employees in our 864 m2 (9300-sf) facility.

SMC: What type of signage does your shop primarily make?

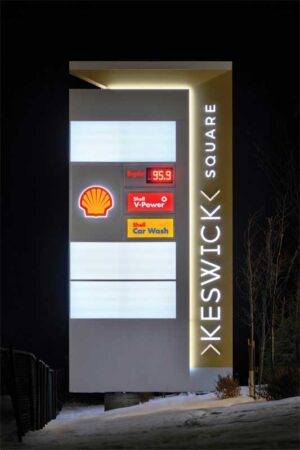

MP: City Image Signs specializes in working closely with storefront businesses, multi-location companies and franchises, general contractors, facility owners, and developers in the execution of permanent and illuminated signs. These can range from building-mounted fascia and projecting signs to large-scale projects involving freestanding structures, and comprehensive packages.

As we carry a cUL electrical certification, our illuminated signs meet and exceed electrical code in all Canadian provinces and throughout the U.S.

SMC: What type of projects have you been working on recently?

MP: The shop has been actively providing signage to several of our house account customers who are expanding their geographic reach into various parts of the country. As such, we are currently engaged in several storefront signage projects. The staff is also working on many pylon signs for regional developers.

We recently supplied and installed signage for one of our hospitality customers’ new locations at the Edmonton International Airport—an exciting first for our company.

The company is continuously looking for ways to build efficiencies within different regions of Canada.

SMC: How much of the signmaking process is handled in-house?

MP: The fabrication facility is where the majority of our signmaking process takes place. Though we sometimes leverage our vendor relationships for certain industry-specific signage requirements, our cUL certification ensures the completion of all electrical components and assembly in-house.

SMC: What tools/equipment do you currently use to complete your projects?

MP: Our custom-built signs are made using a variety of equipment, including a Summa vinyl plotter, a MultiCam computer numerical control (CNC) router, a CLN channel letter notcher, and welding machines. We also have a professional spray booth, which allows us to deliver products with a superior finish.

That said, our greatest asset is our incredible staff. Without their extensive knowledge and experience, these tools and equipment would not matter.

SMC: What does your planning and design process involve?

MP: The success of each project can be attributed to the emphasis we put on pre-construction planning. Using a detailed charting process, we are able to learn, acknowledge, and understand all aspects of the project, which enables us to establish a plan prior to the fabrication process. This strategy effectively streamlines fabrication, minimizes change orders, and shortens overall timelines, which ultimately benefits the project and the client.

We employ project managers and project co-ordinators to execute on each milestone in the signmaking process, including estimating, designing, permitting, co-ordinating installations, and collaborating with onsite vendors and landlords to keep the project on track. We work closely with the client to ensure the sign is within the allotted budget and reflects the overall brand and image of the business.