Custom is King: Meeting consumer expectations with a range of print options

by | 18 November 2019 3:58 pm

By Ginny Mumm

[1]

[1]In the eco-solvent market, the addition of specialty colours to the typical cyan, magenta, yellow, and black (CMYK) ink sets has been extremely beneficial to end-users who are looking for more colour control.

Today’s digital printing industry is stronger and broader than ever before. Several key trends are emerging as businesses incorporate more print types on different substrates—the largest of these being a growing inclination toward customization for clients.

In addition to print-service providers (PSPs) who are eager to provide tailored solutions to retain customers and expand market share, a variety of new businesses have also sprung up to satisfy consumer demand for specific offerings, such as printing on coffee mugs, electronics, furniture, and fabrics.

With both established PSPs and relative newcomers needing effective production solutions, manufacturers are aiming to provide easy-to-use, versatile printing equipment.

Also, the demand for superior print quality and faster delivery speed is continually increasing. Manufacturers are responding with equipment that delivers higher quality prints more efficiently, on a wider range of substrates, with brighter and more vibrant inks.

The author examines several types of wide-format digital printing—ultraviolet (UV), eco-solvent, and fabric printing—to explore what is trending, and what lies ahead for these categories as well as for the industry overall.

UV printers: Combining speed and precision

[2]

[2]Manufacturers are responding to requests for increased ultraviolet (UV) printer output and shorter turnaround times with innovative products.

In 2019, UV printer manufacturers remained focused on providing printers in a variety of sizes and formats to allow both new entrants and high-volume producers to access this market.

Roland DGA’s product manager for UV printers, Jay Roberts, notes that raising the height of print beds has become a trend in recent years, especially with the introduction of specialized printers that have a 152-mm (6-in.) clearance.

“The higher clearance allows for printing on a wide range of substrates, including 3D objects, which are a growing part of this market,” says Roberts.

With their ability to print on both pre-manufactured products, such as sheet stock, metals, wood, and plastics, or post-manufactured products, like cellphone covers, coffee mugs, and golf balls, the UV flatbed printer market has benefited enormously from the customization trend.

Manufacturers have responded with varied printer sizes, ranging from benchtop printers to full production models. With the integration of files across devices, migrating to a larger printer as production needs grow is much easier. In addition, hybrid UV printers offer combined flatbed and roll-to-roll capability, enabling users to handle a wider variety of jobs, while UV printers/cutters allow integrated contour cutting of items like labels and decals.

Inks are equally important. In fact, Robert says today’s designs frequently incorporate ‘pops’ of colour, and printers are using more gloss and white ink, along with orange, blue, and violet. Further, vibrant colours and special effects are being employed more often.

That said, manufacturers are working to address colour management challenges.

“When you talk about ‘colour management,’ the word, ‘management,’ is the hard part,” says Roberts. “Manufacturers are focusing on raster image processor (RIP) software improvements to increase repeatability and consistency across devices, which would further allow a shared visual appearance based on the colour profile and Delta E of each device.”

[3]

[3]In addition to the traditional signage and decals that make up the core business applications, many customers are looking to be able to match certain Pantone or other spot colours for higher-end applications like vehicle graphics.

Another trend to note is the increasing need for variable-data printing (VDP).

“Businesses launching large retail campaigns are customizing their point-of-purchase (POP) displays by taking the general concept of their message and tailoring it to accommodate the needs of the local market,” says Roberts. “Manufacturers are continuing to emphasize VDP in their latest offerings.”

One of the biggest trends Roberts has observed is an increasing demand for a single printer that will allow users to produce large volumes of boards at high speed as well as high-quality, detailed work at a slower speed.

“Sign shops are being asked to ‘do it all’ these days, and they need a printer that can manage both high volume and high-detail runs,” he notes.

Roberts expects the next wave for UV printing to include a transition toward new ink types.

“There’s a lot of discussion about conductive inks and other innovations that will broaden the range of applications,” says Roberts. “If there’s a substrate out there we need to print onto, the technologies and products will advance to meet that need.”

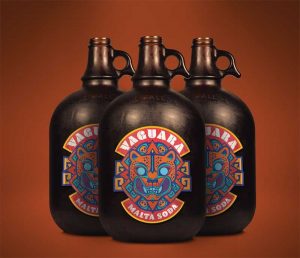

Eco-solvent printers/cutters: Wider ink gamut and greater productivity

[4]

[4]Traditional signage and decals make up the core business applications in the eco-solvent printing business.

In the eco-solvent market, continued evolution in printing equipment and inks has been driven by user feedback.

“End-users are asking for faster lamination, improved performance, and a wider colour gamut—and manufacturers are responding,” says Roland’s product manager of digital print, Daniel Valade.

“The ability to easily match logo and branding colours requires an expanded colour gamut compared to what we have seen in the eco-solvent market over the last five years. The addition of specialty colours to the typical cyan, magenta, yellow, and black (CMYK) ink sets has been extremely beneficial to end-users who are looking for more colour control.”

The trend toward versatility is also continuing in the eco-solvent printer market. Print shop owners are increasingly looking to provide a ‘one-stop’ solution to their clients.

“In addition to traditional signage and decals that make up the core business applications, many customers are looking

to be able to match certain Pantone or other spot colours for higher-end applications like vehicle graphics,” notes Valade.

Along with improved colour management, features like integrated printing and cutting offer streamlined workflows.

“Manufacturers are building on core features to create equipment that is reliable, easier to use, and more efficient,” says Valade.

Going forward, he predicts manufacturers will be focused on developing equipment that can print at the highest levels of quality, while also improving overall productivity.

“Ideally customers want superior quality with the fastest drying ink, plus technology that balances features to make the workflow as efficient and productive as possible—that’s what we’re aiming for,” says Valade.

Printing on fabric: More and better fabric options

[5]

[5]Specialized multi-function dye-sublimation printers simplify production for soft signage and textiles by direct-to-fabric printing, while also allowing users to print onto transfer paper for customizing rigid signs, merchandise, and other hard surfaces.

The market for digital fabric printing is expanding rapidly, the results of which can

be seen everywhere. Today, one can see digitally printed T-shirts, fabric signage, and interior decor in retail spaces, offices, and homes. PSPs are looking for ways to dip into these complementary products, and manufacturers are providing a range of equipment to allow them easier access to fabric printing solutions.

Roland’s product manager for textiles, e-commerce, and supplies, Lily Hunter, feels most PSPs are looking for a ‘one-size-fits-all’ or ‘one-size-fits-most’ fabric printer.

“What I hear all the time is ‘I know I need to get into fabric printing,’ because it will help them with short runs or expanding into other markets,” says Hunter. “Many shops are looking to replace their outsource spending with in-house production.”

Manufacturers are responding with versatile offerings, such as specialized multi-function dye-sublimation printers, which offer production onto soft or rigid substrates, as well as fluorescent and CMYK inks. These simplify production for soft signage and textiles by direct-to-fabric printing, while also allowing users to print onto transfer paper for customizing rigid signs, merchandise, and other hard surfaces.

“Dye-sublimation printers are a great solution for PSPs who are looking to broaden their product offerings and want the flexibility of both direct-to-fabric and dye-sub transfer printing,” says Hunter.

For those that are new to fabric printing, Hunter recommends considering a smaller direct-to-garment (DTG) printer.

“Smaller DTG printers are a great introduction to digital fabric printing. These printers are easy to use, have a low investment cost, and a small footprint,” says Hunter.

[6]

[6]Those new to fabric printing should consider a smaller direct-to-garment (DTG) printer. These printers are easy to use, have a low investment cost, and a small footprint.

Overall, printer manufacturers are working toward providing turnkey solutions for digital fabric printing.

“Fabric printing used to be more of a niche market, but with the broadening range of applications, it’s more important than ever to make equipment that’s reliable, robust, and user-friendly,” says Hunter. “Today, many manufacturers are turning to online support solutions and instructional videos for sharing best practices from setup to finishing.”

Some of the demand for fabric printing equipment is being fuelled by innovations in fabric manufacturing. Newer polyester fabrics that mimic linen, silk, or cotton can be dye-sublimated for a range of apparel and decor applications. Media manufacturers in Europe have even developed a gauzy, woven material that acts as a heat transfer fabric, which can then be adhered to non-polyester fabrics. Further, advancements in primers and other treatments for fabrics have led to black T-shirts that can be dye-sublimated.

Ink manufacturers are creating newer formulations that increase the colour gamut and extend outdoor durability as well as adhesion to a variety of textiles. In addition, the overall industry trend toward vibrant, eye-catching colour has influenced the development of fluorescent inks.

“Fluorescent colours are incredibly popular for everything from uniforms and tennis shoes to accent colours for interior decor,” says Hunter. “In fabric printing and the digital printing market overall, customizing is still the big thing, along with short runs. People want the ability to create unique and specialty personalized items.”

She predicts the next wave of innovation in fabric printing will involve an expanded range of substrates as well as increased options for fabric decoration.

“Manufacturers are working toward developing a suite of equipment to help their clients customize and decorate onto fabrics,” says Hunter. “Overall, we see people getting much more creative. We want to give businesses the tools they need to succeed.”

The future awaits

[7]

[7]In addition to foam core and other signage, ultraviolet (UV) flatbed printers are increasingly used to print customized decor such as tabletops, wall hangings, and decorative tiles.

With the many recent improvements in digital printing technology, Roland president and CEO, Andrew Oransky, expects the market for customized products will continue to grow.

“The good news is most printers already have equipment in-house capable of many types of custom applications,” he says. “Manufacturers are leaning into customization with printers that can do even more.”

Another area for progress lies in helping PSPs unlock more value from their software.

“The newest RIP software offers tools including updated registration systems for print/cut, basic image editing, variable data, new colour management choices, and even automatic generation of special colour plates for white, gloss, and other special effects,

all of which can help increase productivity, efficiency, and accuracy,” says Oransky. “Even experienced users are often surprised when

we show them additional features they can access—and the time they can save—by simply incorporating these software improvements.”

Today, manufacturers are focusing on refining usability and introducing products that can create new revenue streams for clients.

“Understanding how products are used, and how they fit into the overall workflow and businesses of users will allow us to develop products that address specific needs and create new opportunities for printed product sales,” says Oransky.

Ginny Mumm is a freelance consultant for digital inkjet printer/cutter provider Roland DGA. For more information, visit www.rolanddga.com.

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/11/Corporate-Lobby_Roland_TrueVIS_VG2_series_printer-cutters.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/11/Roland_IU-1000F_high-volume_UV_flatbed_printer.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/11/Vehicle-Wrap_Roland_TrueVIS_VG2_series_printer-cutters.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/11/Decal_Growler_Yaguara-Malta-Soda_Roland_TrueVIS_VG2_series_printer-cutters.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/11/FlagBanners_zoo_Roland_Texart_RT-640M_multifunction_dye-sub_printer.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/11/Roland_VersaSTUDIO_BT-12_direct-to-garment-printer.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/11/Small_sign_Roland_VersaUV_LEF2_series.jpg

Source URL: https://www.signmedia.ca/custom-is-king-meeting-consumer-expectations-with-a-range-of-print-options/