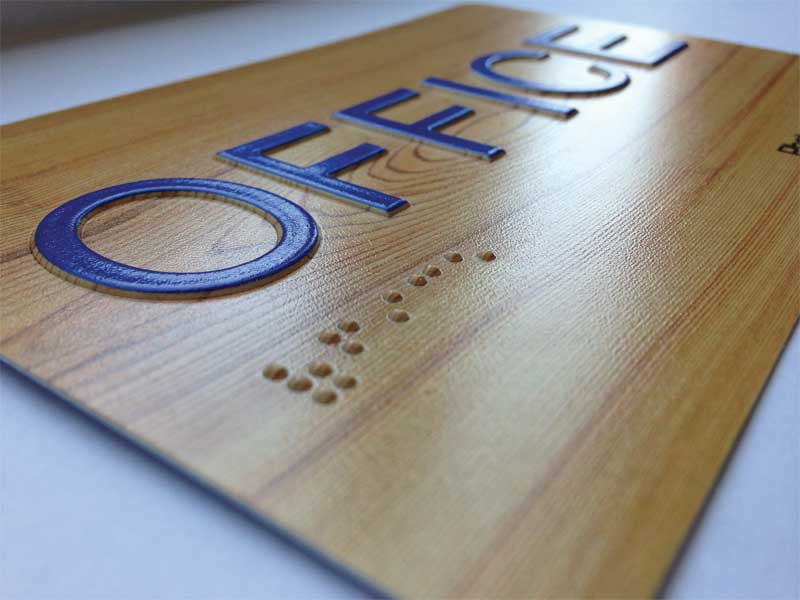

UV-LED printers can add texture to create raised elements, including braille dots on accessibility signage.

Photo courtesy Direct Color Systems

Ink improvements

Bulk ink systems, originally developed with high-production facilities in mind, have now also reached lower-production UV-LED printers. Unlike single-use ink cartridges, these systems are refillable and allow for 100 per cent use of the available ink. They are available as industrial-strength stainless steel tanks to help minimize the need for maintenance.

White ink circulation systems have also been added to complement the bulk ink tanks. These automatically stimulate the entire white ink vessel to help provide optimal opacity, so there is no need for users to manually shake it.

A layered approach

For accessibility signage, the first step is to create or import a braille design that is fully compliant with the applicable regulations. This file is sent to the RIP software, which in turn manages how it is printed onto a non-coated substrate.

All of the components of an accessibility sign can be printed this way, including not only the braille dots themselves, but also raised text and pictograms, at the click of a mouse. A colour-matched background can be printed, too.

Some UV-LED machines print multiple passes or offer a clear overprint, but for a true textured graphic with fully dimensional characteristics, the best approach is to layer in the ink in a precise pattern, based on the tonal qualities of the original artwork. Today’s advanced software can determine the peaks and valleys for the output.

By reducing the number of production steps, printing braille signs in this way can be anywhere from 30 to 115 per cent faster than well-established raster method (where a router drills holes in a substrate, into which a special tool inserts durable spheres) and photopolymer process (where resins are UV-cured and washed out to leave only the raised elements behind).

The same technology, of course, can also add value to practically any other short-run products, from awards to promotional items to other specialty signs.

With files from Direct Color Systems, which manufactures commercial and industrial UV-LED inkjet printers, and Fujfilm, which develops UV-curable inks. For more information, visit www.directcolorsystems.com and www.fujifilm.ca.