In traditional LED signs, cables run from the one or two transformers that reduce voltage, taking energy to each module and then each LED, in different parts of the sign. As lower-voltage electricity must travel relatively long distances to reach each LED, relatively large amounts of that electricity are wasted and heat is produced. For the sign to operate effectively, this heat needs to be dissipated, which is usually done by installing fans inside the sign that, in turn, consume more energy, require more cables and produce more heat.

A more useful design aims to reduce the length of the lower-voltage cables by placing transformers right on the LED boards they power. If higher-voltage cables take electricity from one LED panel to the next and each board contains its own transformer to lower the voltage right where the energy needs to be used, then the amount of heat generated diminishes tremendously. And as no fans are needed, energy consumption is lowered even more.

Further, if an LED display does not use its power supply at its maximum capacity, then the energy will be used much more efficiently, making the LED sign run cooler and less prone to failure. A transformer that is run at full capacity will overheat and give out quickly.

There are many areas where principles of good product design can be implemented. The back of an LED panel, for example, can use vertical fins to create a convection cooling effect. The temperature generated inside the board warms up the fins and the heat rises, forcing cooler air to surge to the bottom, creating a tunnel of cooling air that continues to pass through the LED panel.

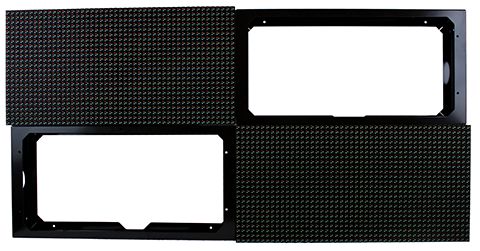

Lighter, thinner and enclosed modules

As electronic devices of all kinds become thinner, lighter and slicker, the same is being demanded of LED signs. A bulky cabinet no longer appears modern or sophisticated, no matter how bright its light may shine.

A tendency toward simpler, modular, enclosed LED signs is not merely an esthetic trend, however; by keeping LED modules sealed and clean, they are less prone to complications and failures and significantly easier to service.

In cabinet-style LED signs, each panel has a sealed face, with any exposed electronics on the backside covered by the cabinet to which they are bolted. Inside the cabinet, fans blow in air from outside to keep the electronics cooled. This outside air, however, is filled with contaminants and moisture, which are particularly deleterious to electronics.

Self-contained, sealed LED panels without fans and bundled cables not only produce less heat, but also protect their electronics much more effectively against damaging agents.

The Imperial Theatre in Sarnia, Ont., incorporated LED-based digital signage into its marquee in 2014. Since then, ticket sales have risen, as (a) more people notice the sign and (b) multiple events can be advertised at the same time.

Sealed LED panels also enable modular design, whereby they are assembled like a puzzle, by snapping one into the next. A modular LED sign is much easier to service, as all of the parts enclosed in one panel can easily be removed and replaced. Cabinet-style LED signs, on the other hand, require an expert on location to open them, study the nest of wires and try to detect where the problem may be—or send the whole sign back for repairs.

Further, modular LED panels can be kept in stock and shipped as needed, whereas cabinet-style signs often require months for assembly before shipping.