Digital Signage: The LED sign design revolution

by all | 9 September 2015 10:16 am

[1]

[1]Photos courtesy Cirrus LED

By Guadalupe Tofalo-Davtchev

Over the past few years, the light-emitting diode (LED) digital signage sector has seen vast change. Fundamental shifts

in LEDs, software and hardware have forced manufacturers to adapt quickly, particularly in the face of innovations in competitive technologies.

Hardware, in particular, is becoming lighter, smaller and faster, with microprocessors and microcontrollers becoming more powerful every day. As per ‘Moore’s law,’ the number of transistors that can be squeezed into an integrated circuit has doubled approximately every two years. Advances in software have kept pace, enabling rich applications in devices as small as smartphones.

Technology has also become more energy-efficient, not merely because customers are environmentally conscious, but also because they are protecting their wallets. No one wants to spend extra money on increased consumption of electricity.

Digital displays have become brighter, sturdier and less expensive. This trend involves deconstructing and rethinking every part of an LED advertising board to keep up to date with competitive technologies, lest they take over the market.

Hence, the following are some factors that need to be kept in mind when developing the next generation of LED panels.

[2]

[2]Many cabinet-style LED signs feature only one transformer, long, exposed cables and blowing fans, all of which reduce energy efficiency.

Energy efficiency

Rethinking the way electricity is used by an LED display sign has involved the reduction of wasted energy and, thus, the reduction of costs, but also an increase in reliability.

As the law of conservation of energy states in physics, energy cannot be created or destroyed, merely transformed. Any electricity that is ‘wasted’ in a device like an LED display is actually transformed into heat, through a process referred to as resistive heating. This poses a problem, as small, delicate electrical components risk overheating and failing.

Resistive heating is also the result of friction caused when an electric current flows through a given material. Some materials (like wood) offer a lot of resistance, while others (like copper) put up very little, but there is always some level of resistance, which produces heat. The friction is created by microscopic collisions between electrons.

Joule’s first law (Q= I2*R*T) states the amount of heat released (Q) is equal to the square of the electric current flowing through a conductor (I) multiplied by the resistance of the conductor (R) multiplied by the time during which this happens (T). So, to reduce the amount of heat lost or released—i.e. increase energy efficiency—it is necessary to diminish I, R and/or T:

- I: Electrical power can be transmitted at different voltages. As counterintuitive as it may sound, the higher the voltage, the lower the current, since the amount of electric power is equal to the product of voltage and current (P= E*I). So, at a higher voltage, a lower current is needed to obtain the same amount of power. That is why electricity is transmitted at higher voltages and then converted to lower voltages through transformers in most electrical devices. LED sign systems, for their part, include one or more transformers to lower the voltage of the electricity coming out of the outlet.

- R: To reduce the resistance of a conductor, most electronic devices—including all LED displays in the market—use copper, which is known for its properties of low resistance and high conductivity. Pretty much the only way to reduce resistance further would be to use gold cabling instead of copper, so it is more practical to work on reducing I and T instead.

- T: The longer it takes for electricity to travel, the more it is wasted as heat. For LED signs, this translates into longer cables causing panels to heat up more than shorter cables.

In traditional LED signs, cables run from the one or two transformers that reduce voltage, taking energy to each module and then each LED, in different parts of the sign. As lower-voltage electricity must travel relatively long distances to reach each LED, relatively large amounts of that electricity are wasted and heat is produced. For the sign to operate effectively, this heat needs to be dissipated, which is usually done by installing fans inside the sign that, in turn, consume more energy, require more cables and produce more heat.

A more useful design aims to reduce the length of the lower-voltage cables by placing transformers right on the LED boards they power. If higher-voltage cables take electricity from one LED panel to the next and each board contains its own transformer to lower the voltage right where the energy needs to be used, then the amount of heat generated diminishes tremendously. And as no fans are needed, energy consumption is lowered even more.

Further, if an LED display does not use its power supply at its maximum capacity, then the energy will be used much more efficiently, making the LED sign run cooler and less prone to failure. A transformer that is run at full capacity will overheat and give out quickly.

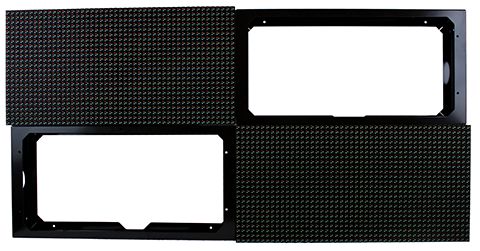

[3]

[3]Sealed, modular LED panels are assembled like a puzzle, by snapping one into the next.

There are many areas where principles of good product design can be implemented. The back of an LED panel, for example, can use vertical fins to create a convection cooling effect. The temperature generated inside the board warms up the fins and the heat rises, forcing cooler air to surge to the bottom, creating a tunnel of cooling air that continues to pass through the LED panel.

Lighter, thinner and enclosed modules

As electronic devices of all kinds become thinner, lighter and slicker, the same is being demanded of LED signs. A bulky cabinet no longer appears modern or sophisticated, no matter how bright its light may shine.

A tendency toward simpler, modular, enclosed LED signs is not merely an esthetic trend, however; by keeping LED modules sealed and clean, they are less prone to complications and failures and significantly easier to service.

In cabinet-style LED signs, each panel has a sealed face, with any exposed electronics on the backside covered by the cabinet to which they are bolted. Inside the cabinet, fans blow in air from outside to keep the electronics cooled. This outside air, however, is filled with contaminants and moisture, which are particularly deleterious to electronics.

Self-contained, sealed LED panels without fans and bundled cables not only produce less heat, but also protect their electronics much more effectively against damaging agents.

[4]

[4]The Imperial Theatre in Sarnia, Ont., incorporated LED-based digital signage into its marquee in 2014. Since then, ticket sales have risen, as (a) more people notice the sign and (b) multiple events can be advertised at the same time.

Sealed LED panels also enable modular design, whereby they are assembled like a puzzle, by snapping one into the next. A modular LED sign is much easier to service, as all of the parts enclosed in one panel can easily be removed and replaced. Cabinet-style LED signs, on the other hand, require an expert on location to open them, study the nest of wires and try to detect where the problem may be—or send the whole sign back for repairs.

Further, modular LED panels can be kept in stock and shipped as needed, whereas cabinet-style signs often require months for assembly before shipping.

Smarter hardware

Apple’s iPhone introduced the advantages of integrated multi-sensor technology to the masses, changing what they expect from—and how they interact with—technology forever. LED signs can keep up by incorporating similar sensors to help make operation easier and reduce the need for maintenance.

The following are several practical applications for sensors in LED signs:

Temperature sensors

By measuring the temperature of an LED board, sensors can help detect if it is getting dangerously close to overheating, send a notification via the cloud to the operator and shut the panel off before a failure occurs.

Current sensors

Similarly, by measuring currents and voltages, a sensor within an LED module can trigger an alarm in case of overload and automatically shut off the device.

Position sensors

From accelerometers to gyroscope sensors, this type of sensor detects the motion of a device and whether it is positioned vertically or horizontally. By using sensors to recognize each LED panel’s position within a sign and communicating that information to the central processing unit (CPU), this technology could become a game-changer for the industry, as the CPU can then identify where and in which panel each pixel should appear and map the panels automatically. This can save a lot of time and money in sign installation and, for that matter, allow customers to change the shapes of modular signs as desired.

Humidity sensors

This type of sensor measures changes in moisture and could thus send a message alerting the operator if water enters the sign.

[5]

[5]Edmonton-based Insight Medical uses LED screens to complement its standard signage with regular updates.

Light sensors

Already common among digital signs, this type of sensor detects ambient light levels, so the sign’s brightness level can be automatically adjusted for optimal visibility and energy efficiency at different times of day. This is particularly important in situations where sign brightness and dynamic content are subject to regulation by local bylaws.

Pressure and strain sensors

Potentially, sensors that measure changes in pressure and send alerts accordingly could be helpful for signs installed at high altitudes and/or subject to very high winds.

With these capabilities in mind, there should be constant communication between the CPU and the controllers in each LED panel, so it is clear right away if one of the panels stops transmitting data. In this sense, sign controllers can also become smarter, constantly monitoring the ‘health’ of the display, making adjustments as needed and sending messages to the owner, so problems are noted even when no one is looking at the sign at the moment.

Other ‘logic’ functions can also be programmed into the sign to make ongoing diagnostics and repairs easier, such as an indicator light that blinks, changes colours or turns itself off to signify whenever a tile is not receiving data, power, images or video feeds.

Richer software

One component that is often overlooked in discussions of LED displays is the software that controls them. Generally, LED signs are sold to sign shops with free, pre-installed software, without which the displays cannot operate; but not all software is created the same.

The more user-friendly the software is, the more likely the sign’s operator is to create eye-catching messages and update them frequently. In this sense, software can mean the difference between a successful advertising display and one that fails to attract new business.

At the very least, the software’s user interface should allow the sign’s owner to easily produce professional-quality images and videos, set up schedules and offline playlists and flexibly change messaging.

The need to adapt

The aforementioned are just a few of the ways technological advances can improve LED-based digital signs to better meet customers’ needs and expectations. Electronic message centres (EMCs) cannot afford to lag behind other digital signage formats; they will need to take full advantage of cost-saving innovations and more effective technologies to ensure their relevancy in the years to come.

Guadalupe Tofalo-Davtchev oversees digital marketing for Cirrus LED, which manufactures digital signs and develops cloud-based content management software. For more information, contact her via e-mail at marketing@cirrusled.com[6].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/09/IMG_5926.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/09/Cabinet-Display.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/09/IMG_1371.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/09/IMG_5912.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/09/Insight-Medical-OS-3.jpg

- marketing@cirrusled.com: mailto:marketing@cirrusled.com

Source URL: https://www.signmedia.ca/digital-signage-the-led-sign-design-revolution/