Dye Sublimation: The next generation of POP displays

by all | 28 October 2016 10:00 am

Photos courtesy Sawgrass Technologies

By Robin Kavanagh

Point-of-purchase (POP) signs and displays are essential to any business that welcomes customers into either a permanent bricks-and-mortar or a temporary ‘pop-up’ store. Not only do they have to showcase their products for sale, but they also have to capture customers’ attention and persuade them to make a purchase. POP signage has a great amount of communicative responsibility and power in the retail marketplace, so it only makes sense to ensure such displays are as effective and eye-catching as possible.

While many technologies offer the ability for signmakers to create full-colour POP graphics, none can truly compare to the visual impact of dye-sublimated signage. By delivering the high-resolution photo and graphic printing capabilities currently possible, as well as bright colours to make people stop and look, sublimation is particularly well-suited for interior signage applications. And with the addition of fluorescent inks and an expanded gamut, the colour matching capabilities of sublimation are greater than ever. As such, sublimation can help open new doors for sign shops that are looking for a bigger piece of the POP graphics market.

How it works

Dye sublimation is a decorating technology that has become easier today for any sign business to adopt. It can be applied to both hard and soft substrates, including polyester-based fabrics, metals, glass, ceramics, wood, plastics and more.

Sublimation ink is made up of solid dyes suspended within a carrier fluid. As such, the ink is viscous. A sign shop will need to use a printer specifically designed for sublimation, to ensure printheads are not damaged and the highest-quality prints possible are achieved.

As with other graphic production processes, it is important to start out by working with customers to design striking graphics that will send the right message to the target audience. This may involve drawing upon the skills and creativity of an in-house graphic designer or a trusted consultant.

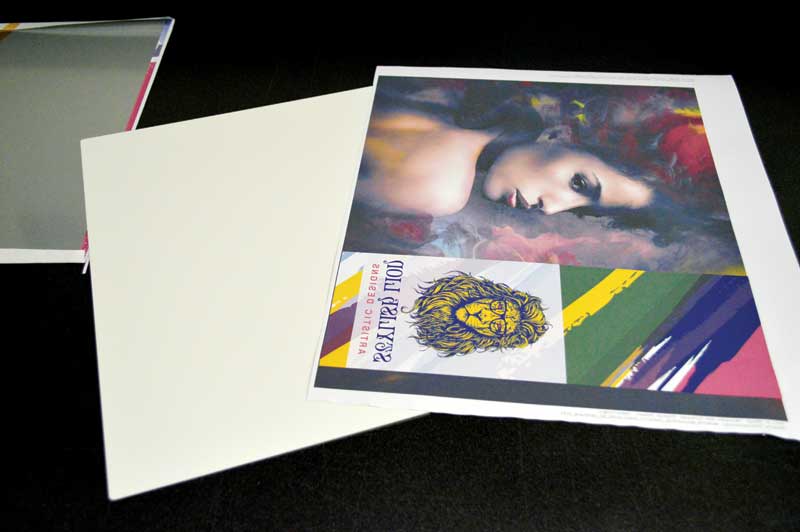

Colour matching capabilities have been expanded with the addition of fluorescent inks.

There may even be press-ready artwork provided by the customer, but if not, desktop graphics software—particularly sublimation-specific design programs—can marry the photos, images, text and colours that will work best for the task at hand, with the physical properties of the substrate in mind.

Once the artwork is finalized, it is printed onto sublimation transfer paper. The paper is then affixed to the substrate and both are placed in a heat press, which fully infuses the image(s) into the surface of the substrate. This is accomplished through both heat and pressure. First, the heat in the press turns the dye solids into gases and opens up the polymers in the substrate. Secondly, the pressure pushes the dye gases into the opened polymers.

Upon cooling, the polymers close up again and trap the gases, which also turn back into solids. Thus, the colouration is permanently embedded into the surface of the substrate and will be able to withstand a full breadth of environmental factors, such as extreme heat, chemical-based cleaning and touching.

POP applications for sublimation

POP displays come in all shapes and sizes. They are defined not so much by their physical properties as by their purpose. That is to say, any sign that communicates information a customer needs to consider when making a purchase in a retail environment is, by definition, a POP display. The displayed content can include special offers, menus, price lists, product information, attention-grabbing images, corporate policies and more.

While it may be best-known in shops that produce flags and banners, sublimation can be applied to both soft and rigid substrates, as mentioned, and has proven a highly versatile and economical method for printing all kinds of POP displays. Large-format sublimation printers can indeed output banners and flags, but also high-visibility fluorescent signs, table panels, wall murals and high-resolution floor graphics, among other applications. Further, sublimated graphics can be used to build entire display systems to promote a particular product line, draw attention to a special message or create a desired atmosphere for a retailer’s overall brand experience.

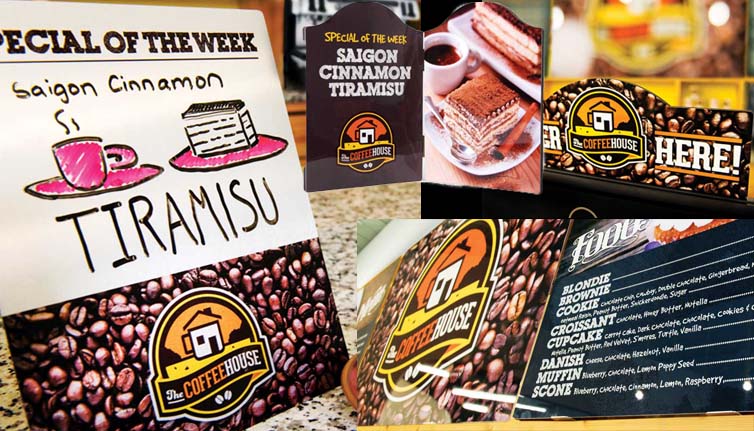

There are also midsize and desktop sublimation systems for creating smaller signs, such as those designed to showcase specials at the cash register counter. Small plastic, aluminum, glass, ceramic and even wooden signs can be placed on display throughout the store to share product information, pricing, discounts and directions. There are many possible options for the technology.

Why sublimation?

Looks are everything when it comes to the effective performance of signage. Sublimation delivers greater colour gamut and definition than vinyl lettering, etching, engraving and other signmaking methods. It delivers high-resolution prints by its very nature, with recent advances in technology providing the capability to print up to 1,440 x 1,440 dots-per-inch (dpi). By combining this technology with the growing number of substrates that can accept sublimation’s dye-based inks, a wider range of POP displays can benefit from a unique recipe for success.

And due to the superior graphic reproduction and durability of sublimated displays, they can command a higher price from clients, who can see how the value of sublimated signs is greater than their other standard options. A client will pay more for a sublimated menu featuring a design created specifically to complement his/her business’ interior décor, for example, than for

a simpler, more generically printed menu. A sign shop that can offer both options boosts its potential for profits.

With regard to durability, there is a diverse and growing range of commercially available substrates for creative POP displays. Rigid substrates like aluminum, fibreglass-reinforced plastics and hardboard have proven highly effective for sublimated signs of many types, including ‘floating’ or flush-to-the-wall panels, murals, architectural elements, sandwich boards, interior décor, functional signs (e.g. for wayfinding) and dry-erase boards, among others. Even ceiling tiles can be printed.

At the flexible end of the spectrum, textiles can become soft signage for a variety of applications, including table throws, floor mats and stretched-fabric exhibitry structures.

Sublimation opens the door to many additional revenue streams because one printer can produce images on hundreds of different substrates. This allows signmakers to operate a one-stop shop for many of their clients’ needs.

If a new hotel is opening, for example, a sublimation-equipped shop can produce not just its interior and promotional signage, but also artwork for the lobby walls, linens featuring the hotel’s logo and name tags and uniforms for the staff.

Sublimated display graphics offer superior graphic reproduction and durability compared to those produced with other methods.

How to get started

A comprehensive dye sublimation system combines a number of different components. As mentioned, for graphic design work on a computer, it is a good idea to access some form of sublimation-specific software. There are many options when choosing a printer designed for sublimation, along with inks, transfer paper and a heat press. It is important to consider these products methodically before making a purchasing decision.

Indeed, research is always the first and most important step when considering the addition of any printing technology to a sign business. The process should start by assessing the shop’s current markets, which other markets will be targeted and what specific products will be offered to them. This will help the signmaker get a better idea as to the size of system needed and, for that matter, the size of the budget that can be allotted for it.

With this in mind, sign shops are recommended to choose the smallest sublimation system that will accommodate the largest sizes of printed applications it expects to offer. The following are the three main categories for printer sizes:

- Desktop models: 356 to 483 mm (14 to

19 in.) wide. - Mid-level roller printers: 0.6 to 1 m (25 to

42 in.) wide. - Wide-format printers: 1.1 m (44 in.) or wider.

Similarly, the heat press needs to be large enough to accommodate the printer’s widest possible output. Note the heat press is usually the most expensive startup purchase for a sign shop adding sublimation to its capabilities. Sublimation-specific design software can also be pricey. As such, it is very important to take inventory of existing assets before determining what needs to be added. Some shops already have a heat press and can thus save a significant amount of money upfront.

Once it is clear what scale of system is the right fit for a sign shop’s needs, the next step is to find as much information as possible about the various options available in that category. Generally, “you get what you pay for,” in that shopping around for the least expensive system is no guarantee of finding the best or even a reliable system. Instead, it is a good idea to attend a few trade shows and see the systems in actual use.

In addition to asking for demonstrations from manufacturers and/or resellers who have lots of hands-on experience with sublimation equipment, signmakers should also network with their peers who have owned and operated the software, printers and heat presses for at least a few years. This is a valuable context for asking for recommendations, learning from past challenges and avoiding potential pitfalls.

Design, print and press

Getting into sublimated display work can be a profitable move for any sign business. Today’s relatively straightforward ‘design, print and press’ process makes POP display production quick and easy, enabling shops to turn jobs around quickly and command higher prices than for graphics produced with other technologies.

More importantly, sublimation enables a sign shop to diversify its offerings, so it can offer more to its clients than its competitors can. It’s a win-win move for signmakers and their customers and represents a new frontier for the industry as a whole.

Robin Kavanagh is public relations (PR) manager for Sawgrass Technologies, which develops dye sublimation and digital printing inks for customized products. For more information, visit www.sawgrassink.com[1].

- www.sawgrassink.com: http://www.sawgrassink.com

Source URL: https://www.signmedia.ca/dye-sublimation-the-next-generation-of-pop-displays/