SMC: How much of the sign installation process is handled in-house?

TD: None, we outsource our installations and that benefits our clients. All installers are not the same; each one has their own speciality. Some have specialized electrical experience, another might have a large crane, some will even provide services into towns we didn’t know existed. During sign installations, certain problems can arise from time to time that may not be accounted for. Our installers have seen it all, and with their own experiences know how to troubleshoot these issues and get the installation done right.

Also, the installers we work with have the proper training and hold certifications for installation. The crews are professional, knowledgeable, and very safety minded. They take no risks with our clients’ investment and no risks with personal safety.

SMC: What tools/equipment do you use to complete your projects?

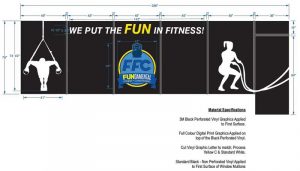

Creating final drafts before manufacturing and installation is a very critical step. At this point, colours need to be accurate, details need to be reviewed, and dimensions confirmed. This is also a good time to check if there may be any hiccups during installation.

TD: We use design software consisting of Photoshop, Illustrator, and Corel to produce designs, renders, and scaled drawings. Our sign partners are chosen based specifically on their expertise and state-of-the-art equipment (digital printers, plotters, environmentally friendly paints, metal bending, welders, etc.) in order to produce exactly what the client wants.

SMC: What does your planning process involve?

TD: Our planning process starts with a client’s idea. After that, we jump through hoops to get them what they want within their timeline and budget. Sometimes customers request something that isn’t plausible; permits won’t allow it or the materials they want to use will not work for the type of sign, or the cost to make it would be over the top. This is where we really shine! We will suggest more appropriate materials and design options and educate them as to why.

First meetings are always the most important time spent with the client. This is where they get excited about their ideas coming to life. Often customers are nervous about turning their vision into a reality. After all, it is an important decision which sends a message or makes a statement that everyone will see, and, despite what

the old saying suggests, “everyone does judge a book by its cover.”

From there, we may do a site walkthrough, take pictures and/or conduct a site survey. If we are not available, we would arrange for one of our installers to take this on, especially if measuring at height is required. Having the installer involved at this stage also allows us to see how they interact with the client and establish that relationship. It is important for us to identify if they can work together and establish a rapport should the sign need servicing in the future.

After an idea is agreed upon, we will start designs, choose colour schemes and select hardware and materials. These designs are then presented to the client and any changes are discussed.

Then, once a price is agreed upon, we turn our attention to picking the correct vendor who can provide the type of sign requested and within the customer’s timeframe. Permit application is also done at this time to ensure there are no issues prior to manufacturing the sign.

Final installation is capped off by attending the site to wrap up the project with completion photos. It is another equally important step as there will be times when a customer may not be on site when the installation happens. We can provide completed job photos for their records.

Finally, when the sign is near completion, we turn our attention to contracting the installer and confirming logistics. Once the sign is complete, the installation will commence. Our installer will test the signs prior to leaving site and take completion pictures.

SMC: How is technology changing your business?

TD: There are now ways to manufacture signs that are more environmentally friendly, reduce waste, and are made from sustainable products. Other examples include new vinyl materials and inks that last and hold their colours longer. New adhesive technologies also allow for reusable, repositionable, and re-sticking of vinyl. This means less waste during manufacturing with error forgiveness.

SMC: What is the key to staying successful in this industry?

TD: Our business is based on who we know and trust to get the job done at the best

price without compromising perfection. It is important to listen to your clients’ wants and needs and give it to them. Repeat business and recommendations are gold. That’s when you know you are successful in the industry.

SMC: How has COVID-19 affected the start-up of your new business?

TD: COVID-19 has been a blessing in disguise. Due to the initial fear caused by the pandemic, many businesses put their advertising, including signed contracts, on hold. For us, this resulted in layoffs due to a shortage of work. However, that provided us with enough uninterrupted time to put together a business plan that centred around the notion of “let’s do this, we’ve got nothing to lose.” This was the best time to take action knowing things will look up very soon and we can be there at the re-start.

Creating a proposal for the customer to review is a very important step in the process. Nothing is worse than having to guess exactly what it is you will be receiving. Drafting renderings allows us the ability to fully understand where the customer would like things placed, as well as identify sizes and colours.

SMC: What are the future plans for your business?

TD: Our future plans include entering the U.S. market and growing our sales force. We will continue to develop relationships with vendors and installers. Elevated Signs is on a mission to “rise above our competition.”