Rotary

Rotary engraving machines have also significantly increased productivity for the sign industry. A single router can automate the entire process of producing braille signs, for example, by routing the sign’s pictogram and text, drilling raster braille pockets and, finally, inserting the rasters into the sign.

Routers are well-suited for engraving metal, polyvinyl chloride (PVC), high-density urethane (HDU), medium-density fibreboard (MDF) and wood. Indeed, they are the best choice for processing the widest range of substrates. And with the use of a long plate, they can enhance workflow further by handling oversized materials.

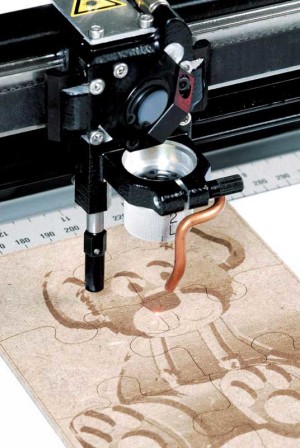

Laser engraving is the preferred process for cutting acrylic letters with a flame-polished edge and can process high-resolution raster images.

Besides engraving, of course, routers are commonly used to cut already-printed substrates. Sign shops have also found new revenue streams by using routers for personalization, promotional and other specialty engraving applications. They can engrave on uneven surfaces, ‘deep engrave’ metal for industrial plates and part marking or even engrave elegant and ornate jewellery and awards with faceted toolmarks.

Routing is the most efficient engraving process for large, filled text. There are ‘2.5-D’ and 3-D options for sign elements, moulds and dies. Another advantage is no exhausting or filtration is required.

Working together

In the final analysis, while laser and rotary engravers offer different strengths and capabilities, they also complement one another and can prove useful together in a high-volume production environment. They have both proven themselves beneficial, for example, in the design and production of creative point-of-purchase (POP) displays.

Similarly, productivity can be further increased with the addition of bevelling machines, metal or plastic shearing tables, cutter-grinders, saws, corner shapers and engraving enamel. All of these tools and consumables have helped modernize production processes in the sign industry and optimized profits, while still fostering artistic creativity.

Robert Hernandez is a territory sales manager, Anthony Harris is applications and contracting manager and Terri Bristow is marketing specialist for Gravotech, which designs, manufactures and distributes engraving and laser systems and consumables. For more information, visit www.gravotech.us.