Fabricating graphics and components

As Holman began to fabricate all of the exhibit’s fixtures, sample units were sent along to the ROM for testing.

“They reviewed how everything would work,” says Roach, “and we figured out with them where we wanted everything to go.”

Meanwhile, the ROM team’s initial sketches and renderings were developed into detailed designs for the exhibit’s wide-format graphics.

“They had to use our templates,” Roach explains. “They couldn’t finalize the graphics’ designs until we had built the pieces that would display them.”

“I would say graphics comprised 40 per cent of the project,” says Khawaja. “There were hundreds of pieces in total.”

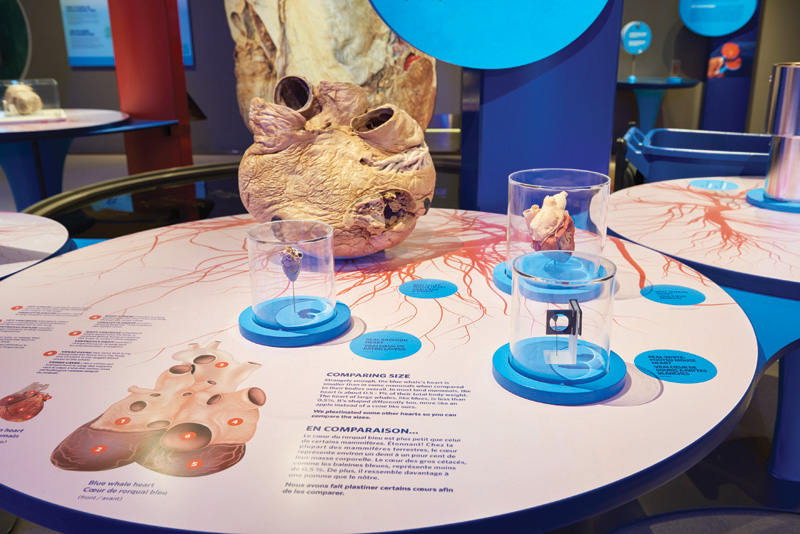

Among these were graphic pillars to identify each section of the exhibit, reader rails, heat- bent polyvinyl chloride (PVC) foam-board directional signs, ‘stations’ with printed information, infill wall panel graphics, pre-mounted table graphics and a 1.4-m (4.5-ft) tall ‘milk carton’ to illustrate how much milk a mother blue whale produces for its calf each day.

Holman has increased its in-house digital printing capabilities in recent years at its 3,716-m2 (40,000-sf) fabrication facility. The table panel graphics, for example, were direct-printed onto polystyrene (PS) using a flatbed press, mounted on painted plywood and coated with an acrylic layer to protect them. For rear-mounted graphics, on the other hand, the images were printed on optically clear PVC films with a roll-to-roll (RTR) press, then mounted onto acrylic.

There were also digital and interactive elements. Bluecadet’s offices in New York, N.Y., developed a video game called Licence to Krill, for which Holman printed the housing’s graphics. In another area, the ROM set up a system to digitally project ultra-high-definition (UHD) ‘4K’ video onto a large wall.

Installing on-site and on-time

The installations began in February and continued through March.

“We made a lot of modifications in accordance with the on-site conditions,” says Roach. “Some of our signs couldn’t fit where we had planned to hang them, for example, because of the sheer size of the whale!”

In addition to Holman’s staff applying graphics, another company was brought in to install wall murals. The exhibit opened on March 11, just in time for families with children off school for March Break.

“Thousands of people came through that week,” says Khawaja.

“The show definitely shattered some records,” says Roach.

The exhibit was not complete when it opened, however, as the ‘plastination’ of the whale’s heart in Germany had not yet been finalized. It arrived at the ROM in May, providing a significant update to the exhibit in time for the Victoria Day long weekend, accompanied by more of Holman’s interpretive graphics. There have also been other graphic changes as new information is added to the exhibit.

“We have an ongoing relationship with the ROM and are always tweaking parts of the exhibit,” says Khawaja.

The exhibit finishes its current run this month (September), but may travel to other museums in the near future, requiring further graphic updates.

“We hope to be involved in those, too,” says Roach.

With files from the ROM, Holman and Bluecadet. For more information, visit www.rom.on.ca, www.holmanexhibits.com and www.bluecadet.com.