Adding new dimensions

In a 2016 InfoTrends report titled ‘Beyond CMYK: The Digital Print Enhancement Opportunity,’ co-author Jim Hamilton reported, “30 per cent of the total colour pages printed in North America and Western Europe—nearly 1.8 trillion pages—currently receive some form of special effects, enhancements or embellishments.”

Such effects are now possible for wide-format graphics, too, thanks to advances in UV-curing printers, varnishes, primers and white inks. PSPs can produce unique, eye-catching output by printing multiple layers and textures and isolating inks and varnishes at various points throughout an image. These applications can be referred to as ‘dimensional printing.’

Varnish

The addition of a layer of gloss to certain elements of an image can enhance its visual impact beyond that of a flat matte graphic.

When creating an out-of-home (OOH) ad for soda or beer, for example, the addition of a gloss varnish to the droplets of condensation on the featured bottle can make it look like it is really ‘sweating,’ creating a much more realistic impression for the viewer, who is more likely to look twice and feel an emotional connection with the product.

In another example, varnish applied to an ad for a luxury wristwatch can make the crystal face appear to pop off the page and, for that matter, can allow the manufacturer’s logo to rise from the substrate. In such cases, the main full-colour image is first printed with standard cyan, magenta, yellow and key/black (CMYK) inks; then the gloss layers are printed separately, using a special varnish, to create a predetermined density or thickness.

Texture

The capabilities of UV-curing inkjet printers can also stretch the possibilities for wide-format graphics by achieving a textured finish.

For a sophisticated replica of an oil painting, by way of example, the original image file can be manipulated with design software to create artificial layers, as a cost-effective way to reproduce the tactility of brush strokes and crackling paint. Once these parts of the image have been isolated, they are assigned separate spot-colour ink channels. Each of these channels is printed in sequence, using white ink, to build up the right levels of texture. Finally, the full-colour image is printed on top of the white ink, creating the effect of a hand-painted canvas.

Another example of this type of effect can be created with a textural photo print depicting a brick wall. Following the same concept, the ‘height’ of brick is built up with one white ink channel and the texture of the mortar is created with another. Layering the ink in this way can mimic the porous nature of brick and coarse mortar. Finally, the full-colour inks are laid down over the white.

Lenticular animation

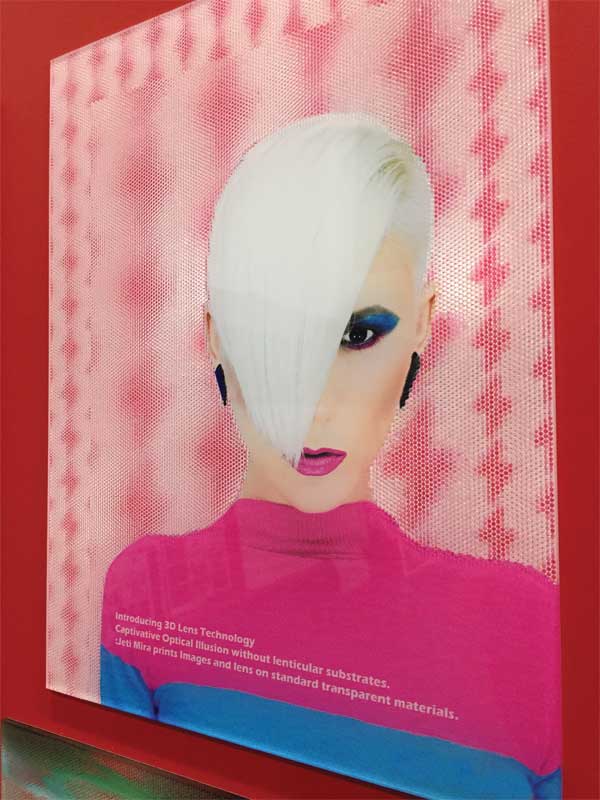

Another purpose for depositing UV-curable inks and varnishes onto a substrate in multiple layers is to create a three-dimensional (3D) ‘lens’ effect, without requiring a lenticular material.

Lenticular applications combine a series of images to create an illusion of motion, through simple animation, as the graphics are viewed from different angles. Traditional lenticular printing is a precise multi-step process that requires special substrates.

Now, however, a similar effect can be achieved with standard transparent media, such as a polycarbonate or acrylic. Depth is added to the substrate by layering varnish to build sufficient height for carefully tuned arrays of tiny lenses.

First, software is used to create the precise pattern. Next, the printer outputs the graphics in multiple layers, starting with a white background on the transparent substrate. After the sheet is flipped and registered, the lens pattern is printed using a clear varnish.

This process can be applied to posters, point-of-purchase (POP) displays, trade show graphics and decor, among other projects.

Unique possibilities

The above are just a few examples of dimensional printing’s creative applications. As such technology continues to be developed, others will also become possible, such as printing 3-D effects on recycled paper. There are certainly many unique possibilities for using inks and varnishes and for combining ‘static’ and ‘moving’ images with depth, so as to make

new graphics stand out in the marketplace.

Brent Holmes is an Agfa Graphics account manager for Western Canada. This article is based on a seminar he presented in April at the BC Sign & Graphics Show in Burnaby, B.C. For more information, visit www.agfagraphics.com and www.bcsignassociation.com.