By Bryan Ballreich

With the current crisis, many machines have been sitting idle for long periods of time. This simple variation in operating frequency can potentially cause mechanical issues, which can be avoided with the right routines.

Liquid-ink printing devices are designed to be in continuous production—that is what makes them the preferred technology

of sign and graphics professionals across the globe. With the current crisis, many machines have been sitting idle for long periods of time. This simple variation in operating frequency can potentially cause mechanical issues, which can be avoided with the right routines.

As businesses reopen, the following tips can help print service providers (PSPs) get their inkjet devices ready for production.

1. Empty the waste tank

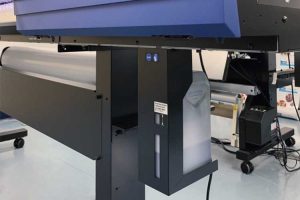

Image 1 shows the waste cartridge on the lower right side of an advanced large-format digital printer/cutter

Image 1 shows the waste cartridge on the lower right side of an advanced large-format digital printer/cutter, while Image 2 shows the waste cartridge inside the right cover of a benchtop ultraviolet (UV) printer. These devices will still continue to drain waste ink during the automated cleaning cycles, even during long periods of non-use. Waste ink that exceeds the capacity of the waste cartridge will eventually overflow and, in some cases, may cause mechanical damage. To avoid these issues, empty the waste tank before leaving the device dormant for any length of time, and again before starting to print.

2. Check and agitate the ink cartridges

Depending on the ink type and the manufacturer’s recommendation, it is important to gently remove the ink cartridges one by one and agitate them slightly. This will mix the liquid completely and counteract any possible settling.

This step is particularly important for white-ink cartridges as most white inks are thicker than other ink types, and the coloured components within them can settle and separate over time. Settling can also occur in the ink lines that run from the cartridge to the printhead, the reservoirs above the printhead, and even in the printhead cap and exit tubes. Therefore, it is recommended white-ink machines undergo a rigorous cleaning and printing exercise after long periods of inactivity.