Greening the sign industry

by Matthew | 18 April 2012 12:21 pm

[1]

[1]Photo by Peter Saunders

By Julie Sommerfreund

The wide-format printing sector, like many others, is making a major shift today to reduce its impact on the environment. As sign shops small and large alike implement sustainability measures in response to customer demand, to meet new regulatory requirements and to make a difference in their communities, ‘going green’ is quickly becoming a business necessity. They are realizing many environmental measures not only are good for people’s health and the planet, but also can be profitable.

Shops that have successfully shifted their business toward green benchmarks have reported such benefits as reduced operating costs, improved worker health and safety, enhanced community relations, reduced regulatory risk, increased employee retention and, in some cases, diversifying their product lines in the marketplace.

Like many other jurisdictions, by way of example, Toronto is combining regulatory requirements and program support to help businesses transition into the ‘green economy.’ A variety of municipal bylaws and programs have been developed to promote businesses’ sustainability.

The following three are particularly relevant to wide-format print providers operating in the city:

- The Chemicals in Toronto: Reduction and Awareness in our Community (ChemTRAC) program—Environmental Reporting and Disclosure Bylaw under Toronto’s Municipal Code, Chapter 423.

- The Sewer Use Bylaw under Toronto’s Municipal Code, Chapter 681.

- The Backflow Prevention Program—Water Supply Bylaw under Toronto’s Municipal Code, Chapter 851.

ChemTRAC

The objectives of the ChemTRAC program are to protect public health and to support business sustainability by reducing toxic chemicals in the municipal environment.

[2]

[2]Pollution prevention strategies for the wide-format printing industry are generally aimed at reducing the use of solvents in inks, cleaners and paint removers. File photos

The program includes the following three main elements:

- A bylaw that requires facilities in Toronto to track and report their use and release of 25 priority substances.

- Educational resources and services to support the ‘greening’ of local businesses through pollution prevention and innovation.

- Public access to information about chemicals used and released in Toronto, to empower the community and further motivate reductions.

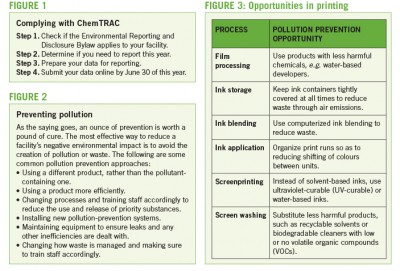

Toronto’s Environmental Reporting and Disclosure Bylaw took effect on January 1, 2010. For the printing and publishing sectors, annual reporting started in 2011, with an annual deadline set on June 30 (see Figure 1).

Businesses are subject to the bylaw if they are based within the city and reach the reporting thresholds for the 25 priority substances. These include common air contaminants like particulate matter and volatile organic compounds (VOCs), as well as toxic substances like benzene, dichloromethane and tetrachloroethylene.

Toronto Public Health (TPH) identified the priority substances in 2007 at levels in the city’s environment that posed health concerns. These common air contaminants have been linked to breathing difficulties, coughing, wheezing and the worsening of both heart and lung disease. These effects can result in an increase in visits to the doctor or hospital, the use of medication, hospital admissions and even early deaths.

[3]The effects not only last during times of high air-pollution levels, but can also cause long-term damage. And long-term exposure can lead to serious health problems, including reproductive defects and cancers.

[3]The effects not only last during times of high air-pollution levels, but can also cause long-term damage. And long-term exposure can lead to serious health problems, including reproductive defects and cancers.

The most effective way for any business to reduce its negative impact on the environment is to avoid the creation of pollution or waste in the first place, rather than try to clean it up or manage it after the fact (see Figure 2). Compliance with ChemTRAC and the bylaw will help Toronto-based businesses take their first steps toward pollution prevention. Tracking the use and release of the priority substances for bylaw-mandated reporting will in turn provide detailed data to help facility managers identify inefficiencies and opportunities for improvements. That which can be measured can be managed.

ChemTRAC has published a ‘Going Green Guide’ for the printing and publishing industry, offering information about a variety of pollution prevention strategies. In the wide-format printing sector, the most typical use and release of toxic substances have involved VOCs in solvent-based inks. Smaller releases of tetrachloroethylene and dichloromethane are also common, due to the presence of these substances in cleaning solvents and paint removers. Also, nitrogen oxide (NOx) and fine particle (PM2.5) releases can arise from fossil-fuel combustion in process heating.

[4]Hence, pollution prevention strategies for print providers are often aimed at reducing the use of VOCs in inks and other products (see Figure 3). Alternatives to solvent-based inks include bio-based, water-based or low-VOC inks. The emission of tetrachloroethylene can also be reduced by using alternative cleaning solvents and paint removers that do not contain it. Another strategy to reduce the releases of priority substances is to use emission control devices.

[4]Hence, pollution prevention strategies for print providers are often aimed at reducing the use of VOCs in inks and other products (see Figure 3). Alternatives to solvent-based inks include bio-based, water-based or low-VOC inks. The emission of tetrachloroethylene can also be reduced by using alternative cleaning solvents and paint removers that do not contain it. Another strategy to reduce the releases of priority substances is to use emission control devices.

Sewer Use Bylaw

Toronto’s Sewer Use Bylaw, under Chapter 681 of the Municipal Code, carries the following objectives:

- To protect water quality.

- To help facilities identify ways to reduce and/or eliminate pollutants at the source.

- To continuously improve the quality of biosolids.

- To help protect infrastructure and workers.

The bylaw sets more stringent limits on most of the 11 heavy metals listed in Ontario’s Guidelines for Utilization of Biosolids and Other Wastes on Agricultural Land and includes 27 toxic organics. It requires pollution prevention planning for Toronto businesses, including print providers, who release any of the subject pollutants into the city’s sanitary, combined and storm sewers.

Some print service providers in Toronto have adopted initiatives like product substitution, equipment modification, product reuse and liquid waste elimination. Many have won awards for their environmental initiatives.

[5]

[5]Alternatives to solvent-based inks include durable aqueous inks. Photo by Peter Saunders

Backflow Prevention Program

Toronto’s Water Supply Bylaw (Municipal Code, Chapter 851) came into effect on January 1, 2008. The objective of the Backflow Prevention Program is to ensure the safety of the city’s drinking water by preventing potential backflow of private water systems.

Normally, water flows from the public supplies into private water systems. Sometimes, however, the flow reverses, causing backflow.

Back-siphonage and back-pressure are common causes of this reversal. Backflow poses a concern for the public, because it can potentially result in the contamination of the public water supply with chemicals, toxic substances, communicable bacteria and pathogens or non-potable water.

So, the program focuses on isolating private water systems in certain premises from the general waterworks. More than 30,000 facilities throughout Toronto are directly involved under the program and are required to install a premise-isolation backflow device. The printing industry—other than ‘dry’ digital printing—is subject to the bylaw and, given its processes, is classified at a severe hazard level.

Julie Sommerfreund is a health promotion consultant for Toronto Public Health, providing environmental information and education with relation to health policies. For more information or to register for an upcoming pollution prevention webcast, e-mail chemtrac@toronto.ca[6] or visit www.toronto.ca/chemtrac[7] and www.toronto.ca/water[8].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/IMG_3893.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/picture_01.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/picture_031.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2012/04/SM_Apr_2012_HR-78.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/IMG_5132.jpg

- chemtrac@toronto.ca: mailto:%20chemtrac@toronto.ca

- www.toronto.ca/chemtrac: http://www.toronto.ca/chemtrac

- www.toronto.ca/water: http://www.toronto.ca/water

Source URL: https://www.signmedia.ca/greening-the-sign-industry/