Illumination: Fibre optic lighting in signs and displays

by all | 8 May 2017 3:26 pm

[1]

[1]Photo © Schott North America

By Stephen Montgomery

Fibre optics may be best-known to the public for their broad use in residential Internet and other telecommunications services, as they can transmit more data across longer distances than copper- or wire-based cabling. They are also increasingly being implemented for lighting applications, however, including sign and display illumination.

An optical fibre is a thin and flexible tube, made of either glass or plastic, that can carry light from one end to the other. It may be installed inside a cable jacket or externally from a cable (i.e. ‘individually’).

Fibre optic lighting has proven practical for a wide range of industrial, automotive, military, aerospace, medical and scientific uses, but has also found its way into store display cases, swimming pools and spas, landscaping, offices, casinos, holiday decorations, toys and consumer products. Indeed, research shows the overall value of the worldwide market for fibre optic lighting grew to US$312 million in 2016.

While the use of fibre optics in signage is still in its infancy, this could change quickly. The process of assembling, testing and manufacturing fibre optic lighting products already allows for mass production capabilities. Over the next few years, the average prices of these products will be driven lower by these production efficiencies, as well as by quality controls, higher yields, greater competition (in terms of both markets and technologies), improvements in sales, marketing and distribution and other factors. As such, the technology will move on from the ‘development’ and ‘introduction’ stages in the sign industry and into the ‘growth’ stage of its product life cycle (PLC).

Opening new applications

Optical fibres can illuminate a sign by emitting light from their sides, providing an effect similar to neon. They are not nearly as heavy as traditional sign lighting technologies, however, so the labour involved in constructing and installing a sign is reduced, as is the cost of transporting it.

Further savings are achieved over the long term. Optical fibres are durable and do not degrade under normal conditions. Also, since light—not heat—is being sent along the fibre, typically the only maintenance required is at the source of the light, e.g. changing the lamp.

Optical fibre-based signs can display single static or multiple digital messages in more than 256 colours and provide exceptional visual clarity. The main market driver behind their increased adoption, however, is the ability to create and install illuminated displays in entirely new forms and locations, thanks to the attributes of the technology’s unique mix of components:

- The optical fibres themselves, whether made of glass or of a ‘plastic optical fibre’ (POF) polymer.

- The illumination source, whether based on light-emitting diodes (LEDs), halogen or metal halide.

- The related hardware and fittings.

By way of example, optical fibre lighting can operate safely in wet installations, allowing signs to be integrated into swimming pools and fountains. Also, POFs can be woven into carpets and other textile-based surfaces, so as to create illuminated fabric graphics.

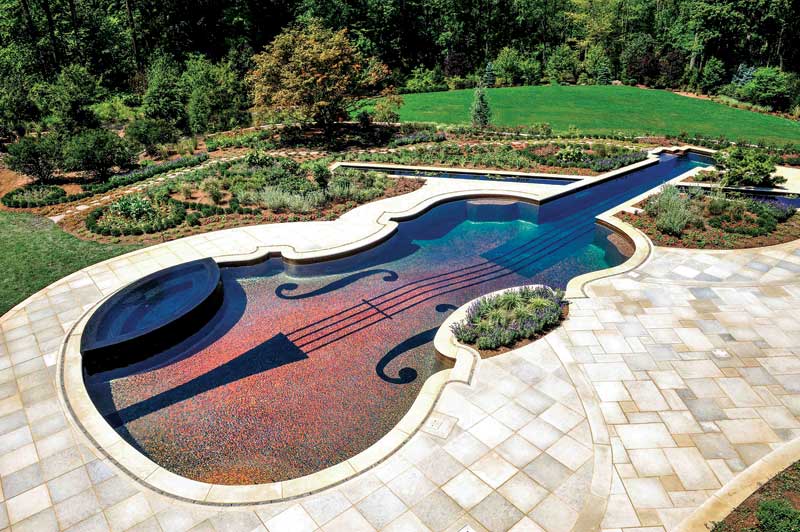

[2]

[2]In this violin-shaped pool, 5,760 fibre optic components interlinked with the tiles delineate the lap lanes by day and light up as the ‘strings’ at night. In addition, a 107-m (350-ft) long fibre optic rope lighting detail illuminates the entire boundary.

Photo courtesy Cipriano Landscape Design

Indeed, the use of optical fibres in signs opens up a whole new range of possibilities, limited only by designers’ and fabricators’ artistic creativity and imagination. Sign shops that are open to including fibre optics in their ‘tool box’ can establish a clear advantage over their competition.

Illuminators

According to Universal Fiber Optic (UFO) Lighting, which manufactures glass fibres, an illuminator—or ‘light engine’—can be thought of as the interface between the electrical supply and the optical fibres. It is a separate unit that contains the lamp or LEDs, ‘feeds’ light through the fibres and, as such, can be set up in a centralized location, a fair distance from the actual sign.

This is why fibre optics can, as mentioned, illuminate signs in wet applications. The illuminator is the only component of the system that houses electricity and can become warm to the touch, so it must be kept in a dry location, but then the optic fibres can stretch out into wet environments, even submerged underwater. The illuminator may also include additional control mechanisms for special lighting effects, such as colour changes, pulsing and twinkling.

Many illuminators for fibre optic systems use a Digital Multiplex (DMX) controller. Originally designed to control light dimmers, this now-standard technology has supported the rise of ‘intelligent lighting,’ such as Glasbau Hahn’s systems for museums, where the illumination of a particular area is reduced or turned off completely when it is not occupied by visitors or staff. Other non-lighting functions can also be handled by DMX systems, such as micro-area climate control for display cases.

[3]

[3]The ability to create and install illuminated displays in new forms and locations is due to the attributes of the components, including the optical fibres, the light source and the related hardware and fittings.

Photo © Schott North America

Light sources

There are, as mentioned, three main types of light sources for fibre optics: LEDs, metal halide and halogen.

The lifespan for halogen lighting ranges from about 1,500 hours for a 100-W lamp to approximately 3,000 hours for a 20- to 75-W lamp. Metal halide lamps, meanwhile, are rated to last 6,000 hours.

LEDs, on the other hand, offer a lifespan of up to 50,000 hours, drastically reducing maintenance costs by maximizing the duration of operation before any bulbs need to be changed. Further, they offer brightness levels equivalent to 100 halogen lamps, save energy, contain no toxic mercury and—thanks to low levels of heat—support the use of plastic fibres instead of glass.

For these reasons, LEDs are increasingly being adopted as light sources for optical fibre-based signage and display applications.

Fibre cables

With no heat or electricity running through them, optic fibre cables are very safe and virtually unbreakable. Thanks to these attributes, they can eliminate many typical restrictions when it comes to designing sign lighting systems.

Optical glass fibre for illumination applications is typically available in a variety of standard bore diameters, ranging from 0.75 to 14 mm (0.03 to 0.55 in.), with wider sizes available for more challenging applications. Multiple diameters can be combined within a single harness, as can varying lengths. The number of output points that can be generated from a single source will depend on the total combined bore diameters of all of the light guides within a system.

Unlike light sources (even LEDs), optical fibres do not lose their light intensity or burn out. So, while an illuminator can experience a reduction of intensity and even a burnout over time, the ability of each individual optic fibre to emit light through its ends or sides will keep on going.

The fibre optic system for a series of halo-lit channel letters at Dubai International Airport in the United Arab Emirates (UAE), for example, comprises a total of 6,000 m (19,685 ft) of end-emitting optic cabling and 130 illuminators with 150-W metal halide lamps. Each letter in the outdoor sign—which spells out ‘Emirates Engineering’—is 2.7 m (8.9 ft) tall.

[4]

[4]Fibre optics can carry light from a single source to multiple points, so as to illuminate a large area.

Photo courtesy Luxam

Side-emitting cabling provides a lower-maintenance, higher-durability alternative to neon or chain lighting. It is suitable for use in water, icy conditions and other extreme weather. It is available in an ultraviolet-stabilized (UV-stabilized) form and treated with algaecide and fungicide.

Non-glass options include polymethyl methacrylate (PMMA) solid optical fibres, such as the aerospace-grade products from Nouvir Lighting, which use the same material found in jet fighter’s canopies, reportedly will not yellow and have been measured to lose only 0.7 per cent of light for every 0.3 m (1 ft) of length. Unlike many glass-based fibre optics, acrylic can remain opaque to both infrared (IR) and ultraviolet (UV) radiation and cannot transfer heat to sensitive displays (such as the exhibit cases in museums).

With all of these options available, it has become much easier today to avoid the environmental effects that would typically harm copper cable. And as optical fibres do not conduct electricity, they can also prevent problems with ground loops and conduction of lightning.

Learning from other markets

Given how the use of fibre optics in signage is still relatively new and not yet widely offered in the sign industry, it is fortunate other well-established lighting applications can provide a helpful ‘test bed’ for how signs might be illuminated in the future.

One important factor, as mentioned, is weight. In the automotive and aviation industries, the lower weight of materials translates into better mileage. With aircraft, especially, weight is a critically important factor in performance.

With fibre optics, weight savings come not only from the fact the material itself is light, but also because the system as a whole can use less copper wiring and far fewer individual lamps, other than the illuminator(s).

In medical and surgical applications, fibre optics for minimally invasive procedures have brought light into places it was previously impossible. Similarly, the technology allows signs to be illuminated in what were previously difficult environments, such as in the middle of a rushing fountain.

Museums, meanwhile, have led the way in taking advantage of fibre optic lighting’s colour temperature. Light-based radiation can act as a catalyst for oxidation, which is particularly problematic when illuminating an exhibit of organic artifacts.

[5]

[5]An illuminator can support special lighting effects, such as colour changes, pulsing and twinkling.

Photos courtesy UFO Lighting

The high level of energy in UV radiation—as emitted by the sun and, to a lesser degree, by fluorescent tubes, metal halide lamps and mercury vapour lights—is especially damaging. UV light is not visible to the human eye, however, so it can be removed from museum exhibit illumination to help protect artifacts without causing any change in appearance.

At the other far end of the spectrum, IR radiation can also prove problematic by causing a rise in temperature when it is absorbed. Fortunately, it too is invisible to the human eye and, thus, can be removed. As mentioned earlier, acrylic fibre optic cabling is opaque to both of these types of radiation.

Even LEDs can cause colour temperature problems. The viewing of classic Impressionist paintings by Vincent Van Gogh and Pau Cézanne, for example, has been negatively affected by LED lamps in museums. Investigators explain these masters’ yellow paint work has instead appeared olive green and brown, due to the high quantity of blue light routinely emitted by the LEDs.

As a result, many museum curators and directors have been rethinking how they illuminate their exhibits. Luxam, a company that specializes in lighting for museums, has turned to fibre optics both to improve light intensity and to deliver a more favourable colour temperature compared to other systems.

The controllable nature of optical fibres via an illuminator is especially helpful for museum exhibits—not merely to turn the lights on or off, but also to showcase differences in colours in artifacts. Further, since fibre optic cables allow an entire object in a display case to be illuminated from a single light engine, the overall presentation allows for more accurate colour comparisons than are possible with individual lights that may not perform exactly the same as each other.

[6]

[6]Combining lenses and optical fibres has proven popular for museum displays.

In everyday lighting, all of this precision may not seem like a big deal, but frequent museum visitors appreciate being able to view relics and pieces of art worth millions of dollars under truly balanced lighting. And colour temperature is certainly important in the sign industry, with respect to ensuring accurate colour management for today’s highly brand-sensitive clients.

Experimenting with components

While fibre optic technology can offer many benefits, some experimentation may be needed. Even the Fiber Optic Association (FOA) itself admits the industry is lacking in standardization. With a broad variety of proprietary products available, it can be hard to generalize about how best to design systems.

That said, every design project will start with some questions in common:

- What is to be illuminated?

- What kind of light is desired (in terms of intensity, pattern, colour and variety)?

- Where and how will the light be output?

- Where will the light engine be placed?

And finally, there is the matter of lensing. By combining optical fibres with lenses, light can be carefully focused on extremely specific points. This capability has already proven popular for jewellery displays and museum exhibits, among other applications.

Stephen Montgomery is president of international business expansion for ElectroniCast Consultants, which forecasts technology trends in the

fibre optic, light-emitting diode (LED) and photonics markets. For more information, visit www.electronicast.com[7].

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/05/FO_Sidelight-with-hand.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/05/FO_violin1.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/05/FO_Lightsource-and-FO.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/05/FO_IMG_2452.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/05/FO_ufoclub.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/05/FO_ufomuseum.jpg

- www.electronicast.com: http://www.electronicast.com

Source URL: https://www.signmedia.ca/illumination-fibre-optic-lighting-in-signs-and-displays/