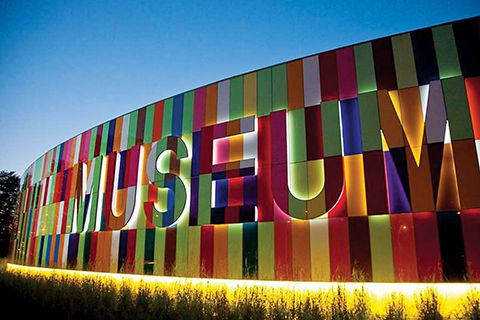

Channel letters, lightboxes and backlighting

There are still many ways to light a sign by day and night, including LEDs, neon, fluorescent and electroluminescent (EL) systems. There are also different techniques for illuminating them, as mentioned, including back, edge, front and halo lighting.

While fluorescent and neon lighting are still used in the sign industry today, LEDs have provided a strong alternative. Indeed, they may yet signal the demise of older technologies.

While fluorescent and neon lighting are still used in the sign industry today, LEDs have provided a strong alternative. Indeed, they may yet signal the demise of older technologies.

Traditional aluminum lightboxes have been effective for decades and remain very common today. Typically 203 mm (8 in.) thick, they have a series of fluorescent tubes mounted inside to illuminate graphics applied to acrylic faces on one or both sides. By today’s standards, however, this traditional method of lightbox fabrication leads to excessive consumption of power.

A typical large-format lightbox, for example, at 6 x 3 m (20 x 10 ft) in size, will require 45 58-W fluorescent tubes for effective illumination. Even if it is operated for only 12 hours a day, it will use approximately 12,000 kW of power per year, for an electricity bill in excess of $1,000 U.S. per year.

Maintenance is another problematic issue for this type of sign. With just one faulty fluorescent tube, the sign presents its graphics poorly; and with 45 or more tubes mounted within a single sign, the likelihood of a fault at any given time is rather high. Flickering and/or broken tubes quickly represent a significant ongoing cost in terms of maintenance.

As a result, it is common to see these signs showing dull patches or shadows across their surface. This flawed presentation will have a negative impact on consumers’ perception of the advertised brand. It simply does not look professional, nor is it bright enough to capture the same level of attention as envisioned at the sign’s inception.

In addition to the previously mentioned benefits of dramatic reductions in energy consumption costs and maintenance needs, LEDs can help save space with thinner lightboxes, provide more even illumination and meet regulatory requirements for sustainability.

LED-backlit LCDs

Much as LED-backlit LCDs have been adopted as consumer TVs, so too are commercial-grade models used exclusively for professional display and digital signage purposes. Software and external hardware are usually added to the system to provide video and sometimes audio content.

Large, industrial LED-backlit LCDs have become common at public facilities like airports and train stations—both indoors and outdoors—to quickly deliver up-to-date information to passengers and passersby. Generally, they operate 24-7 and are wired to a network of other displays.

LEDs can back- or front-light letters or halo-illuminate them for a subtler effect. Photo courtesy Pride Signs

LED screens

LED-based digital signage is primarily known as an outdoor medium, to be viewed from farther distances than LCDs, but it also has indoor applications. In particular, many indoor video walls are now large-scale LED arrays, rather than matrices of thin-bezel LCDs.

Many of these applications are driven by digital out-of-home (DOOH) advertising, which can bring in ongoing revenue to a shopping mall or other venue. At the touch of a button, display operators can switch between facility information, ads, social media, event listings and other content.

“Higher-resolution outdoor displays are in demand,” says Jeff Rushton, president and CEO of Media Resources International in Oakville, Ont., “but indoor ultra-high-definition (UHD) video walls are also a major trend. They are found in train stations, airports, shopping malls and even tunnels.”

Of course, large LED-based displays are well-established as scoreboards in sport venues. Today’s go beyond traditional scoreboard content with full video and sophisticated on-command programming software.