Inkjet Printing: Choosing the right films for window graphics

by all | 28 April 2014 8:30 am

[1]

[1]Photos courtesy Exopack Advanced Coatings

By Jennifer Chagnon

Point-of-purchase (POP) graphics and displays continue to provide a major revenue-generating opportunity for signmakers. According to the Specialty Graphic Imaging Association’s (SGIA’s) recently published 2013 Market Trends & Product Specialties Benchmarking Report, retail stores currently represent the largest market served by sign and graphics companies, while banners, indoor wall graphics and window displays are among the product categories that see the highest demand.

It is a particularly opportune time to take a fresh look at window graphics. While they are not a new application in themselves, the availability of new and improved inks, media, printing hardware and software has raised their achievable quality to a new level.

With today’s digital inkjet printing technologies, signmakers can easily produce one-of-a-kind display graphics to meet regional marketing requirements, as graphic alterations are significantly more cost-efficient than with traditional offset printing.

On the other hand, the emergence of the digital imaging marketplace and all of its new technologies has also made it more challenging for signmakers to select the right media for window graphics. With that in mind, the following are tips for specifying and creating eye-catching window graphics that can be easily mounted and displayed by clients.

Media options

Today’s digitally printable media offerings cover a wide range of materials, textures and adhesion options from many manufacturers, all of which can dramatically affect the look of window graphics. Applications can be produced using clear films, textiles, repositionable polypropylene (PP) and perforated films, among others. It is important to understand the differences before choosing the option that best fits the requirements of the intended job.

Textiles

Textiles can yield high image density, superb colour gamut and a soft appearance. These traits have made them a popular choice today for the printing of window graphics and displays, among other POP applications.

When choosing among textile offerings, signmakers should select media constructed of 100 per cent polyester-woven fabric. Polyester adds durability and dimensional stability.

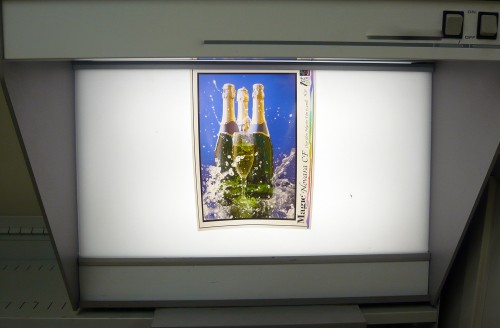

[2]

[2]When clear films are applied to windows, they require a two-sided, pressure-sensitive, optically clear adhesive.

Many printable substrate manufacturers now offer repositionable textiles with a low-tack, non-permanent, pressure-sensitive adhesive and a paper liner for easy mounting. For signmakers who choose this option, it is very important to look for materials that can print ‘full-bleed,’ will not shrink with the application of heat and are designed to prevent edge curling. By allowing the material to the reapplied and repositioned countless times, the low-tack adhesive makes it ideal for both window and wall decal applications.

Clear films

Clear films have become increasingly popular for a number of POP applications, including not only window graphics, but also backlit (‘lightbox’) graphics, colour overlays and screen positives, because they enable strong black printing densities. When applied to windows, they require a two-sided, pressure-sensitive, optically clear adhesive.

There are many clear films on the market today for solvent-based, eco-solvent, durable aqueous ‘latex’ and ultraviolet-curing (UV-curing) inkjet printing systems. Polyester films are the best option, as they deliver the smoothest base uniformity and highest resolution for printed graphics. With the environment in mind, an increasing number of recyclable polyester films have become available.

It is important to note, however, some inkjet printers cannot ‘see’ clear films with their optical sensing/detection mechanisms. For these cases, media manufacturers offer films with edge stripes or a paper interleaf, which add sufficient opacity for the film to be recognized as it is fed through the printer. The stripes are the best option for printers that use edge media sensing, while the interleaf is a good backup measure.

That said, for signmakers who do not wish to use edge stripes or interleaves with their printing systems, many substrate manufacturers also offer clear films with a slight degree of opacity.

Perforated films

Perforated window films are available today for both outside- and inside-surface-mounted graphics and are well-suited for solvent, eco-solvent and latex inkjet printing systems. They help prevent window graphic advertisements from completely blocking light and sightlines.

[3]

[3]A printed graphic’s level of light transmission can be tested in-house.

When selecting perforated window films, one of the keys is to look for the ideal ‘solid to hole’ ratio. For retail window graphics, in general, a 60-40 perforation ratio is ideal, as it will let people inside a store see through to what is happening outside, while people outside the building will only see a solid, vivid image.

Clear liquid laminates are compatible with perforated window films and will provide excellent surface protection. When applying them, the temperature of the film surface should be above 4 C (40 F).

With recent technological advances, some perforated films are now specifically designed to be printed on the adhesive side. To accomplish this, they combine an adhesive with an ink-receptive coating.

One advantage of this innovative design is it eliminates the need to laminate for protection, as window graphics can be mounted on the inner surface of a store window, where they are visible to the outdoors without risk of damage from the elements or vandalism.

Another advantage is graphics can easily be mounted on windows above ground level by someone inside the building, rather than needing a professional installer in a lift truck outside.

These materials require no additional adhesives or mounting tapes and, again, a 60-40 perforation ratio is ideal. To prevent any debris from settling on the printed side of these tacky window films, however, it is important to clean both the printer and the printing area prior to use, as well as place a clean silicone liner on the floor under the printer. Signmakers should unwind a few ‘wraps’ of the material to feed into the printer and then keep it draped on the unwinding roll, without the use of a take-up reel.

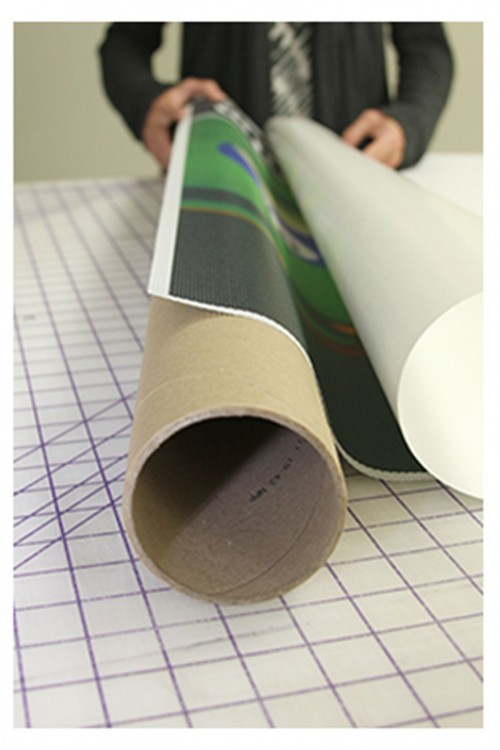

[4]

[4]A wide range of window graphic materials, textures and adhesions are available today.

As with other media options, these inside-surface-mounted window graphics should be applied to a clean, dry glass surface at a temperature of 4 C (40 F) or higher. As the graphic is held up toward the glass, only the top edge should be tacked down at first. Then the rest of the application surface can be touched as the film is gently tacked, working downward and outward, using a soft squeegee or roller or by hand.

When installing a perforated-film window graphic, the film should first be peeled and folded back from about 25 mm (1 in.) of the liner. Once the film is aligned properly along the window, the top edge should be tacked down. From there, the remaining liner can be gently peeled away and the graphic applied evenly by hand, roller or smooth squeegee. The graphic can also be repositioned later.

Repositionable polypropylene

Repositionable PP films with low-tack adhesion are already popular for custom posters, short-term residential graphics and some retail displays, but they are now being increasingly used for both short- and long-term promotional window graphics, as well. PP is sufficiently durable for multiple uses and, unlike vinyl, will neither shrink with heat nor suffer any edge curling.

PP is a well-priced option for maximizing the production of lower-cost indoor and outdoor signage. Many substrate manufacturers offer it with a universal coating, allowing it to be printed across all platforms. By enhancing production flexibility, this allows sign shops to reduce their inventories of multiple substrates.

Once a PP window graphic is unrolled, it should be allowed to flatten at a minimum air and surface temperature of 10 C (50 F), after which it can simply be peeled back from its liner and applied in the desired location. The graphic should be squeegeed with minimal pressure while the liner is removed, smoothing out any wrinkles and bubbles as the film is applied to the glass.

PP window graphics can be reapplied after removing them slowly, lifting at a 90-degree angle. They can also be applied to other smooth, flat, clean surfaces besides glass.

A new generation

As seen in these and other examples, recent advances in technology have opened the door to a new generation of printable media options for highly appealing window graphics. Today’s signmakers can more easily produce high-end images with a softer appearance, using more environmentally friendly materials than before.

Jennifer Chagnon is director of digital imaging for Expopack Advanced Coatings, which develops, manufactures and distributes coated papers, films and specialty substrates under the Magic brand for inkjet printing. For more information, visit www.magicinkjet.com[5].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/03/FIVE.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/03/ONE.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/03/Novara-CF_hi-res.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/03/NewVue_4.jpg

- www.magicinkjet.com: http://www.magicinkjet.com

Source URL: https://www.signmedia.ca/inkjet-printing-choosing-the-right-films-for-window-graphics/