LEDs: A need for illumination standards

By Craig M. Berger

In recent years, many incredible innovations have reshaped the sign industry, but some of these changes have produced new challenges that need to be addressed. Lighting, in particular, is among the key areas where technological developments have caused their own difficulties.

Lighting is the foundation of the modern sign industry. When the first major trade organization, the National Electric Sign Association (NESA), was established in 1944, it was built around a relatively small group of lighting suppliers that kept tight control over manufacturing standards.

Over time, as NESA expanded in scope and became the International Sign Association (ISA), there was a concurrent expansion in signmaking materials and technologies, which made it more difficult to maintain consistency. The replacement of neon lighting with LEDs posed the greatest challenge of all.

Freedom of choice, but not quality

With today’s availability of hundreds of different lighting products have come constant complaints from the signmaking community about inconsistency in terms of standards of quality. Bill Kovacevic, for instance, has witnessed a degradation of quality from up close over his 50 years working as a sign designer and consultant.

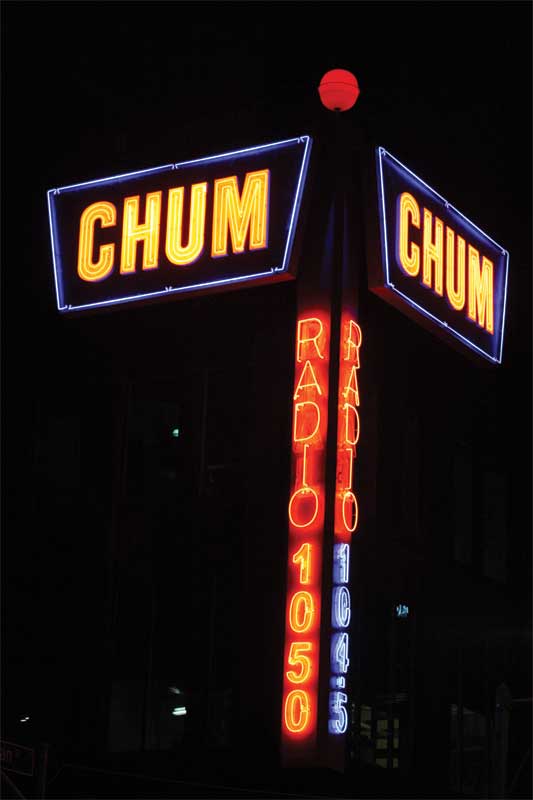

“I started as a designer during a golden age of signs, in 1964,” says Kovacevic, currently a consultant for Pattison Sign Group in Dorval, Que. “Designers had to know every technological aspect of a sign, including then-new developments in thermoplastics. The branding firms I worked with in those days, like Lippincott and Margulies on the General Motors (GM) sign program and Gottschalk and Ash (G+A) for the Royal Bank of Canada’s (RBC’s) illuminated logos, understood how every sign went together and followed standards that were tight and consistent.”

Today, he suggests, the optimal use of advanced LEDs with new materials like direct-to-print acrylic is not widely understood by designers. With this lack of knowledge, specifications have become looser, leading to many lower-quality signs.

The importance of consistency

By contrast, standards are a strong force within the commercial architectural lighting industry. The Illuminating Engineering Society of North America (IES) publishes standards for everything from colour temperature to light output to longevity for dozens of different applications. This allows a residential customer to buy consistent landscaping lights at Home Depot and, at the same time, a laboratory technician to specify the perfect lighting for testing chemicals.

Unfortunately, such standards do not exist to the same degree in the sign industry.

“The lack of clear standards has created a situation where signmakers have a difficult time specifying lighting without extensive prototyping,” says Fritz Meyne, Jr., vice-president (VP) of sales for the Bitro Group, which supplies LED modules for channel letters, sign cabinets and lightboxes.

This scenario poses tough challenges for both sign fabrication shops and original equipment manufacturers (OEMs).

“Without industry-wide standards, high-level lighting manufacturers have a hard time justifying investments in further research and development (R&D), which could yield greater longevity and more consistent output,” says Meyne. “Signmakers think they can get the same quality ordering overseas products online.”

So far, most of the heavy R&D spending has been applied to specific projects, like major brand rollouts, where the importance of lighting consistency is crucial across hundreds of signs. This only helps those sign programs, not smaller projects.