Looking for CNC routers: tips and tricks

by | 18 May 2019 2:16 pm

By Greg Jenkins

[1]

[1]For many smaller signmaking businesses, the performance of computer numerical control (CNC) routers continue to validate investing in this equipment, particularly the impact they have on business growth.

The decision to purchase a computer numerical control (CNC) router can be extremely difficult for some small to medium-sized businesses. On one end, this high-tech equipment offers a sign shop the ability to broaden its capabilities by reducing the time it takes to complete projects, and adapting to future production needs. On the other, companies have to weigh a number of factors when calculating the return on investment (ROI) to ensure it justifies the purchase.

No business has to be reminded about the importance of due diligence for every purchasing decision, including ROI projections. In this case, the analysis should go beyond the obvious. It not only needs to incorporate a thorough understanding of the product, but also an equally comprehensive scrutiny of the vendor as a business partner, including the role the vendor plays in ROI calculations.

For many smaller signmaking businesses, the performance of CNC routers continue to validate investing in this equipment, particularly the impact they have on business growth. Yet, the ROI and success of one company may not necessarily apply to another business with a similar operation. This is why a ROI analysis requires the full co-operation and involvement of the potential business partner whose interests are focused on the company’s growth now and into the future, and not just on making a sale.

The epitome of automation

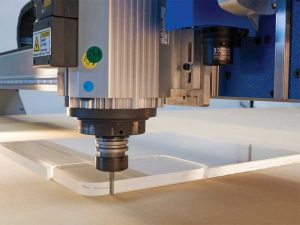

[2]

[2]There is a substantial growth in router usage in the sign and graphics industry, which relies on automation software for converting a wide range of rigid and semi-rigid sheets of plastics, woods, and metals.

For more than two decades, CNC routers have represented the epitome of automation by aiding large and small sign shops in expanding their offerings and capabilities while reducing the amount of time they take to complete a project.

That said, in the first decade of the router’s inception and rapid growth, purchasers faced a number of issues, none of which was related to the machine’s performance, but more so everything to do with the vendor. Unwittingly, buyers were making purchasing decisions in what has been described as the Wild West.

Dozens of small machine manufacturers saw a golden opportunity in producing routers and tried to take advantage of it, sometimes with disastrous results. Within a few years, most of them either folded or merged with other manufacturers. As a result, buyers faced a difficult, threefold dilemma: worthless warranties from vendors who were no longer in business; reliable technical support became problematic, even when companies merged; and distance from the vendor. Instead of nearby facilities that would substantially reduce time and maintenance costs, the purchaser was forced to deal with lengthy wait times for technical support and/or expensive teardowns and shipping.

For many smaller signmaking businesses, the performance of CNC routers continue to validate investing in this equipment, particularly the impact they have on business growth.

These unacceptable scenarios have changed as surviving router manufacturers have become more adept. They developed technological sophistication in ways that were unheard of in the 1990s. Potential purchasers are also more sophisticated in understanding router capabilities, how to use them and, more specifically, determining the ROI for this major purchase. This expertise has been influenced and aided by the number of Internet outlets such as Google and even YouTube where router demonstrations and related information are easily accessible.

Signmaking companies turn to CNC routers for two reasons: the ability of the machinery to automate manual processes and to reduce operational labour costs by using their employees for higher value processes.

The ability to expedite workflow—another ROI factor—explains why there is a substantial growth in router usage in so many industries and markets, including, but not limited to, the sign and graphics industry, which relies on automation software for converting a wide range of rigid and semi-rigid sheets of plastics, woods, and metals.

Changing role of vendors

A vendor who serves only as a supplier and conduit for third-party tech support and maintenance from, what may be, distant locations is no longer enough. Today, vendors have more of a global presence because router users demand it. This presence is expected to include nearby branches that are more than dealerships because maintenance-related delays are the bane of every sign shop.

Even more important for companies is for their vendors to be business partners with proven track records. Buyer support is more likely with secure partners who have proven to be viable and responsive over the years. Business relationships are not intangible when it comes to ROI. If the vendor fails to meet expectations, the ROI will be unacceptable because of inevitable increases in maintenance, lost time, and repair costs (regardless of warranties).

True partnerships should be judged on the vendor’s understanding of the company’s operations, needs, and goals. In addition, potential buyers want reassurance their partner has the expertise to present quantifiable ROI projections, which include the timeliness and reliability of tech support and hiring more skilled technicians to respond to calls immediately. Further, equipment users expect the individual who is answering their calls to be a technician with the knowledge and expertise to troubleshoot machines, software, and cutting processes. Signmakers can lose valuable time when they get an answering service or an automated message.

CNC routers respond promptly and accurately, produce precise tolerance and, in most cases, are capable of four times the output compared to manual processes.

Issues and pain points for CNC routers

While costs and ROI figures are at the top of the list for most sign shops looking to purchase a CNC router, there are other important considerations that play a significant factor. Perhaps the biggest of these are process and workflow.

The router has been proven to significantly improve production, provide quality, and reduce time to complete a project, but it has to be the right router for the business. The machine must be productive for more than five years after the purchase. Considering many routers have a 20-year lifespan, it is incumbent upon the vendor to align the machine’s capabilities with the sign shop’s long-range production plans.

Companies generally take a macro view of financing as they analyze costs, impact on profitability, and short and long-term ROI when making a major investment in equipment such as a CNC router. Before embarking on a month-to-month lease/purchase agreement, there are a number of variables that should be taken into account—particularly if a sign shop is considering having a third-party perform its router cutting and shaping needs, including:

- Reliance on a third-party can lead to other costs as opposed to the savings realized

from manufacturing in-house (e.g. do-overs if the fabricator does not perform the right cut and other freight costs for shipping

to the fabricator). Savings from in-house manufacturing can be as high as 25 per cent when compared to expenditures associated with third-parties. - In many cases, there are longer waiting periods for production completion when a third-party fabricator fills work orders from larger customers.

- There can be a negative impact on cash flow from shipping, labour problems, and other related expenditures.

- Other variables include calculating the costs associated with how often the machine runs, upgrades, and the opportunity for future growth. An idle machine incurs costs as well.

- Cost versus value decision. The former is short term while the latter is strategic. Despite cost concerns, businesses should focus on the long term as a router can function and be productive for nearly two decades.

Other ROI essentials for CNC routers

[3]

[3]Routers represent the epitome of automation by aiding large and small sign shops in expanding their offerings while reducing the amount of time it takes to complete a project.

In addition to all of the considerations mentioned above, a thorough ROI calculation should include the conversion of costs to opportunities. The latter is factored in multiple ways designed to grow the business in the short and long term, such as improving processes, increasing production and quality, and cost savings achieved through converting from manual cutting and shaping to automation.

A ROI calculation should begin by determining the number of labour hours and the associated costs with manually cutting and drilling parts, which could have been cut and shaped quickly using router automation. Another consideration should be what it takes to manually work with various materials in the signmaking process (e.g. plastic components, sign letters, and aluminum parts, etc.). Cutting and drilling require multiple tools and a considerable amount of time and labour. Contrast this with a CNC router in which material is loaded, a corresponding computer-aided design (CAD) file is selected, and the operator simply starts the machine.

CNC routers respond promptly and accurately, produce precise tolerances and, in most cases, are capable of four times the output compared to manual processes. For many sign shops, this typically results in far better use of workers and their time—both of which effectively lower operating costs.

[4]

[4]Potential buyers want reassurance their vendor has skilled technicians who can respond to calls immediately.

ROI also manifests itself with the router’s ability to significantly reduce material waste through nesting—the process of establishing patterns that can be cut closer together. A sign shop’s chief financial officer will notice material costs to be significantly less than they were with a manual process. Further, another positive

this equipment offers is the reduced need for “do-overs” which can occur at an unacceptable rate with manually produced parts.

By reducing the potential for error and the subsequent costs associated, these too an be easily calculated into the monthly savings. That said, the fundamental reason for investing in a CNC router is business growth. Automation opens up the possibility of offering and providing more complex products—a benefit designed to offer more advantages for current customers and attract new ones.

Lessons learned

[5]

[5]

A return on investment (ROI) calculation should begin by determining the number of labour hours and the associated costs with manually cutting and drilling parts, which could have been cut and shaped quickly using router automation.

Every sign shop, including smaller ones, needs to stay ahead of the investment curve if ROI is to meet and exceed expectations. For buyers who have decided to invest in a router, the following 10-item checklist can help one calculate costs and ROI.

- Take time to examine the impact of the machinery on project workflow and manufacturing space.

- Consider additional costs such as the possible need for a larger air compressor,

more electrical work to accommodate the

router, and training staff. - Determine implications for the business such as a possible disruption during installation and training.

- Determine if long-term use of the particular router under consideration will enable the company to achieve future goals, including business expansion, which is one of the most important ROI concerns.

- Demand a business partnership with a provider who can work with the company and help the business flourish without getting in the way.

- Research the quality of the vendor’s technical support and parts replacement.

- All machinery requires constant maintenance, service, and qualified staff to operate. Therefore, it is important to closely analyze how all three will be controlled.

- Be upfront about expectations, and require the same from the vendor.

- Examine the benefits of establishing a partnership with a fully integrated supplier to eliminate potential third-party issues. Having manufacturing support and engineering teams under the umbrella has proven to be better for the business.

- Buy a machine that has the right parts and pieces for long-term growth.

ROI is always based on costs and use. That said, the interconnection of machines means a wealth of data will be collected by today’s CNC routers on a daily basis. As a result, company owners get an up-to-date picture of the real-time ROI status, the machine’s use, and its successful operation.

A business partner who is more than a vendor is an absolute for achieving the maximum ROI. Technological changes and improvements are a given; therefore, it is important to thoroughly study and evaluate the vendor’s ability to provide upgrades integral to business growth.

More importantly, businesses are best served by vendors who are local and can promptly provide service, training, and support. Delays caused by the vendor’s distance can only increase the machine’s downtime and decrease ROI. Parts, advice, and training from the machine manufacturer, while very important, are part of the ROI equation.

The other component is investing in teaching staff to operate and maintain the router properly. Adherence to maintenance protocols should keep the machine operational for many years and substantially reduce the risk of a full stop due to failures from misuse.

Finally, the machinery to be purchased should align with the company’s current and future capacity. This is the best way to improve production workflow, reduce costs, and assure a ROI that justifies the purchase.

Greg Jenkins is vice-president, North American sales for AXYZ, a global manufacturer of computer numerical control (CNC) router machines and knife systems. For more information, visit www.axyz.com/us.

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/05/Trident-6000-front-on-cut.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/05/Trident-Cutting-Acrylic.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/05/Trident-Cutting-Xanita.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/05/AXYZ-Technicians.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/05/Trident-Cutting-ACM.jpg

Source URL: https://www.signmedia.ca/looking-for-a-cnc-routers/