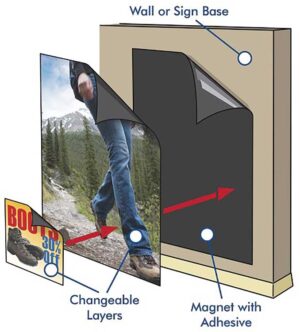

Magnetic graphics systems (printable magnetic and magnetic receptive sheeting) are ideal for displaying frequently changing information or graphics on flat or curved non-ferrous metal surfaces.

Printable magnetic sheeting

Printing onto magnetic sheeting allows companies to offer a variety of promotional items, such as vehicle signs, informational signs, menus, calendars, wayfinding signs, and more. The process has evolved from a two-step procedure of printing on vinyl or another substrate and then laminating the printed image onto the magnet, to the simpler and faster one-step process of printing directly on the magnet. The latter is a much more efficient process as it removes the extra time and costs associated with a two-step process, as well as the occasional extra costs associated with reprinting and reapplying the image when there is trouble with the install and allows to provide a wide range of useful informational and promotional materials to customers without any delaminating or bubbles to worry about.

Choosing the right printable topcoat for a printer is essential. Vinyl and coated surfaces can be printed directly with solvent, eco-solvent, ultraviolet (UV), and latex inks. Paper topcoats are available for aqueous inks, but they would need to be laminated for protection if used outdoors. If one is new to printing on magnets, they should be aware the metal platens commonly featured on roll-fed printers can be an obstacle. This can easily be overcome by covering the platen with styrene, cardboard, or anything thick enough to create an air gap between a ferrous metal platen and the magnetic sheeting so it feeds in and flows out smoothly. Adhering the styrene or cardboard to a precisely cut-out piece of magnetic sheeting can be more convenient than taping it in place on the platen.

Magnetic graphics systems (printable magnetic and magnetic receptive sheeting) are ideal for displaying frequently changing information or graphics on flat or curved non-ferrous metal surfaces.

When printing on magnetic sheeting, it is important to remember some general adjustments for heat, weight, and thickness. For instance, lowering the heat settings usually helps. Magnetic sheeting is heavier and thicker than most substrates, so it is important to take the weight into account, not just when feeding it in, but also when the sheet is coming out of the printer. The printed magnet needs to be supported so it does not hang and create a drag. The magnet needs to flow smoothly through the printer. The printhead height should be adjusted accordingly for the specific thickness of the magnet, so be sure to check the printer’s height limitations.

Magnetic vehicle signs require a minimum of 30 mil thickness for a regular strength flexible magnetic material, which is too thick for some printers.

In recent years, high-energy magnetic sheeting has become available. It can be half the thickness (15 mil) and weight, with the same magnetic strength required for vehicle signs. Be sure to check with the manufacturer for the specific width, thickness, and other requirements, as well as profiles for the printer.