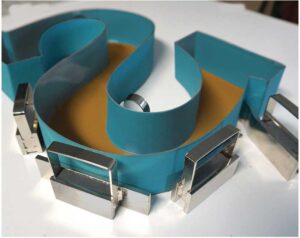

Using handle magnets that firmly anchor channel letter trim caps and returns can save time during assembly on metal tables.

Magnetic tools

Speed and efficiency determine the profitability of most production work, and magnetic tools can be an asset for getting things done around the shop quickly and conveniently.

Vehicle wrap magnets

During a vehicle wrap installation, using magnets instead of tape to hold graphics in place makes each job easier, faster, and more profitable. It is important to use magnets that have the features one needs to do the job right. Be sure to consider:

- Strength: The magnet should be strong enough to hold graphics in position without slipping while still allowing repositioning movement when pulling gently on the graphic.

- Non-scratch: Magnets for vehicle graphic installation should have a protective covering such as plastic, rubber, or felt to prevent scratching of the graphics or vehicle during installation. Be sure to always wipe the contact side of the magnet before each use so the collected debris does not cause scratches.

- Storage: It is helpful to have a good way to block the magnetism when storing so the magnet does not attract all the loose metal tools and parts in the toolbox. A cover, case, or shield that blocks the magnetism when not in use is important.

Magnetic heat gun holder

Another handy tool that makes wrap installation work faster and more convenient is a magnetic heat gun holder, which can hold the heat gun and move easily around the vehicle as needed to always keep the gun within reach. The strength of the magnet and a non-scratch surface are essential factors to consider for this tool. Magnetic heat gun holders are also great for holding a spray bottle or other tools, keeping them up off the ground, and easily in reach.

Channel letter trim cap holding magnets

Just like vehicle wraps, there are different steps to produce channel letters, and magnets can be helpful. Holding channel letters in position with nails is an old and slow process, and with an errant swing of the hammer, one could damage the letter that is being worked on. Magnets once again can add speed and efficiency to the production process. For instance, using handle magnets that firmly anchor channel letter trim caps and returns can save time during assembly on metal tables.

Most channel letter magnets feature solid steel construction, nickel plating, and welded handles for quick and easy repositioning.

A magnetic tool holder can be used to hold the heat gun and move it easily around the vehicle as needed to always keep the gun within reach.

Why magnets?

Magnets are simple, reusable, have permanent power, and come in multiple types, strengths, and forms to accomplish the job needed and are usually a cost-effective solution.

There are a multitude of magnet manufacturers in the industry, so how can one decide what brand to trust?

Since product quality, customer service, and product knowledge are required attributes, one should rely on a manufacturer that will spend the time to partner with one’s company on each project, identify the right magnet for the application, and guide the business through a wide variety of magnet types, sizes, strengths, and functions to meet the project’s requirements and budget.

As businesses continue to adapt and persevere, the versatility and efficiency of magnets can contribute to providing creative solutions and the industry’s continued growth and success.

Mike Gertz has more than 11 years of industry experience as the marketing manager for Master Magnetics Inc., in Castle Rock, Colo. Master Magnetics is an international manufacturer and distributor of all types of magnets and magnetic devices for commercial, consumer, and industrial use. Gertz can be reached at mgertz@magnetsource.com.