Magnets are versatile sign and graphics solutions

by all | 4 February 2021 3:19 pm

By Mike Gertz

[1]

[1]Magnetic sign holders are quickly and easily repositionable and the perfect option for environments that change often.

The COVID-19 pandemic has certainly impacted businesses in many ways. Those that have been fortunate enough to remain open have had to adapt to the changing and challenging circumstances in all areas of their operations.

In addition to the normal promotional marketing materials required for businesses, the need for COVID-19 related signage for safety and social distancing is in huge demand now and will continue to be in the foreseeable future. Retailers, restaurants, contractors, and other businesses have needed health- related signs since the beginning. Adding to the increased demand, there are many other organizations, institutions, and businesses that will now need an extraordinary amount of signage of all types and sizes.

These include healthcare facilities, local and provincial/state governments, public and private schools, religious organizations, recreation facilities, and more.

Printable magnetic and magnetic receptive sheeting, along with magnetic assemblies for holding signs and tools are ideal for all types of signs and graphics as they are simple to use and highly versatile. These options are especially valuable when signs need to be changed frequently to keep information up to date or in non-permanent environments, such as building entrances, store shelves, and displays.

Magnets are ideal for all types of signage, as they provide easily changeable, repositionable, and cost-efficient solutions. Today, there are many different types of magnetic products that can help sign businesses.

[2]

[2]Magnetic graphics systems (printable magnetic and magnetic receptive sheeting) are ideal for displaying frequently changing information or graphics on flat or curved non-ferrous metal surfaces.

Printable magnetic sheeting

Printing onto magnetic sheeting allows companies to offer a variety of promotional items, such as vehicle signs, informational signs, menus, calendars, wayfinding signs, and more. The process has evolved from a two-step procedure of printing on vinyl or another substrate and then laminating the printed image onto the magnet, to the simpler and faster one-step process of printing directly on the magnet. The latter is a much more efficient process as it removes the extra time and costs associated with a two-step process, as well as the occasional extra costs associated with reprinting and reapplying the image when there is trouble with the install and allows to provide a wide range of useful informational and promotional materials to customers without any delaminating or bubbles to worry about.

Choosing the right printable topcoat for a printer is essential. Vinyl and coated surfaces can be printed directly with solvent, eco-solvent, ultraviolet (UV), and latex inks. Paper topcoats are available for aqueous inks, but they would need to be laminated for protection if used outdoors. If one is new to printing on magnets, they should be aware the metal platens commonly featured on roll-fed printers can be an obstacle. This can easily be overcome by covering the platen with styrene, cardboard, or anything thick enough to create an air gap between a ferrous metal platen and the magnetic sheeting so it feeds in and flows out smoothly. Adhering the styrene or cardboard to a precisely cut-out piece of magnetic sheeting can be more convenient than taping it in place on the platen.

[3]

[3]Magnetic graphics systems (printable magnetic and magnetic receptive sheeting) are ideal for displaying frequently changing information or graphics on flat or curved non-ferrous metal surfaces.

When printing on magnetic sheeting, it is important to remember some general adjustments for heat, weight, and thickness. For instance, lowering the heat settings usually helps. Magnetic sheeting is heavier and thicker than most substrates, so it is important to take the weight into account, not just when feeding it in, but also when the sheet is coming out of the printer. The printed magnet needs to be supported so it does not hang and create a drag. The magnet needs to flow smoothly through the printer. The printhead height should be adjusted accordingly for the specific thickness of the magnet, so be sure to check the printer’s height limitations.

Magnetic vehicle signs require a minimum of 30 mil thickness for a regular strength flexible magnetic material, which is too thick for some printers.

In recent years, high-energy magnetic sheeting has become available. It can be half the thickness (15 mil) and weight, with the same magnetic strength required for vehicle signs. Be sure to check with the manufacturer for the specific width, thickness, and other requirements, as well as profiles for the printer.

[4]

[4]During a vehicle wrap installation, using magnets instead of tape to hold graphics in place makes each job easier, faster, and more profitable.

Magnetic strip

Magnetic strip is useful for holding non-magnetic printed materials. It is available with adhesive on the non-magnetic side, allowing the user to attach it to a sign. The sign can then be mounted to any ferrous metal wall or surface, or to any surface that one has applied a magnetic receptive material.

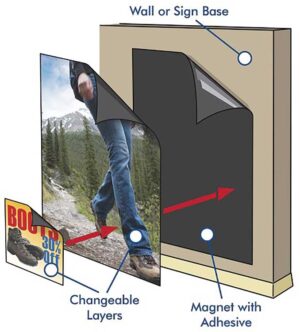

Magnetic graphics systems

Magnetic graphics systems (printable magnetic and magnetic receptive sheeting) are ideal for displaying frequently changing information or graphics on flat or curved non-ferrous metal surfaces. This system is good for frequently changing information as graphic elements can be layered and easily replaced without changing the entire sign or display. A magnetic graphics system can be a helpful solution in a variety of indoor and outdoor environments.

Specialty magnets

Specialty magnets such as magnetic chalkboards or dry-erase magnets can be used on their own or as a re-writable part of a magnetic graphics system. These magnets are a great option as unlike other chalkboards and dry-erase boards, they can be applied on curved surfaces, are easily repositionable, and can be quickly rolled up and transported.

Magnetic chalkboard

Flexible magnetic chalkboard provides a reusable surface for menu boards, point-of-purchase (POP) signage, schedules, and ad specialty items. One can write on or decorate these boards with chalk or chalk markers, then simply erase with a damp cloth to reuse. The durable surface accepts UV, latex, solvent, and eco-solvent ink for permanent printing and cuts easily with a standard plotter or hobby knife.

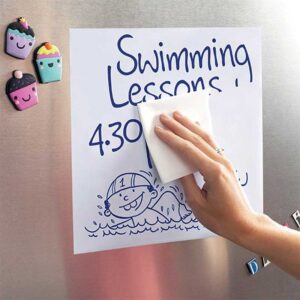

Magnetic dry-erase

This is a flexible magnet with a white vinyl topcoat and a dry-erase laminate, which works with dry-erase markers and pens.

[5]

[5]Magnets are ideal for all types of signage, as they provide easily changeable, repositionable, and cost-efficient solutions.

Magnetic sign holders

For non-magnetic graphics, there is a wide variety of sign holding magnets and hooks including magnetic carabiner hooks for easily mounting and repositioning large vinyl banners with grommets.

Magnetic sign holders have many advantages.These include:

- There is no need for drilling holes in large banners to use fasteners;

- Magnetic sign holders are quickly and easily repositionable and the perfect option for environments that change often; and

- They are a great choice for store shelves, office environments, medical facilities, and much more.

[6]

[6]Using handle magnets that firmly anchor channel letter trim caps and returns can save time during assembly on metal tables.

Magnetic tools

Speed and efficiency determine the profitability of most production work, and magnetic tools can be an asset for getting things done around the shop quickly and conveniently.

Vehicle wrap magnets

During a vehicle wrap installation, using magnets instead of tape to hold graphics in place makes each job easier, faster, and more profitable. It is important to use magnets that have the features one needs to do the job right. Be sure to consider:

- Strength: The magnet should be strong enough to hold graphics in position without slipping while still allowing repositioning movement when pulling gently on the graphic.

- Non-scratch: Magnets for vehicle graphic installation should have a protective covering such as plastic, rubber, or felt to prevent scratching of the graphics or vehicle during installation. Be sure to always wipe the contact side of the magnet before each use so the collected debris does not cause scratches.

- Storage: It is helpful to have a good way to block the magnetism when storing so the magnet does not attract all the loose metal tools and parts in the toolbox. A cover, case, or shield that blocks the magnetism when not in use is important.

Magnetic heat gun holder

Another handy tool that makes wrap installation work faster and more convenient is a magnetic heat gun holder, which can hold the heat gun and move easily around the vehicle as needed to always keep the gun within reach. The strength of the magnet and a non-scratch surface are essential factors to consider for this tool. Magnetic heat gun holders are also great for holding a spray bottle or other tools, keeping them up off the ground, and easily in reach.

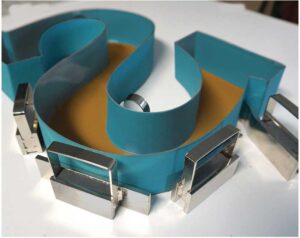

Channel letter trim cap holding magnets

Just like vehicle wraps, there are different steps to produce channel letters, and magnets can be helpful. Holding channel letters in position with nails is an old and slow process, and with an errant swing of the hammer, one could damage the letter that is being worked on. Magnets once again can add speed and efficiency to the production process. For instance, using handle magnets that firmly anchor channel letter trim caps and returns can save time during assembly on metal tables.

Most channel letter magnets feature solid steel construction, nickel plating, and welded handles for quick and easy repositioning.

[7]

[7]A magnetic tool holder can be used to hold the heat gun and move it easily around the vehicle as needed to always keep the gun within reach.

Why magnets?

Magnets are simple, reusable, have permanent power, and come in multiple types, strengths, and forms to accomplish the job needed and are usually a cost-effective solution.

There are a multitude of magnet manufacturers in the industry, so how can one decide what brand to trust?

Since product quality, customer service, and product knowledge are required attributes, one should rely on a manufacturer that will spend the time to partner with one’s company on each project, identify the right magnet for the application, and guide the business through a wide variety of magnet types, sizes, strengths, and functions to meet the project’s requirements and budget.

As businesses continue to adapt and persevere, the versatility and efficiency of magnets can contribute to providing creative solutions and the industry’s continued growth and success.

Mike Gertz has more than 11 years of industry experience as the marketing manager for Master Magnetics Inc., in Castle Rock, Colo. Master Magnetics is an international manufacturer and distributor of all types of magnets and magnetic devices for commercial, consumer, and industrial use. Gertz can be reached at mgertz@magnetsource.com[8].

- [Image]: https://www.signmedia.ca/wp-content/uploads/2021/02/11_magnet.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2021/02/7_magnet.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2021/02/9_magnet.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2021/02/12_magnet.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2021/02/5_magnet.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2021/02/16_magnet.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2021/02/14_magnet.jpg

- mgertz@magnetsource.com: mailto:mgertz@magnetsource.com

Source URL: https://www.signmedia.ca/magnets-are-versatile-sign-and-graphics-solutions/