Making a big impression

by Matthew | 1 May 2012 4:21 pm

[1]

[1]Photos courtesy Epson

By Reed Hecht

Wide-format printing technology continues to see significant changes driven by innovation, market demands and signmakers’ needs. Trends that are redefining the sign industry today include growing environmental requirements and the role of printing in a ‘digital age.’

Digital and print

Many professionals initially perceived the emergence and rapid growth of digital signage as a threat to the wide-format printing sector. Today, however, many companies have discovered how digital signage and printed graphics can remain individually successful, with each playing an important role in certain locations and contexts, and can even work together for the best of both worlds.

Digital signage is preferable in many situations where displayed information must change frequently. Printed signs, which continue to represent the leading market, are suitable for messages that can remain static for some time.

Though digital signage may now seem ubiquitous, it relies on a constant power source and must be installed at specific viewing angles for optimal visibility. It also requires proper ventilation and a protective environment to prevent vandalism and to resist environmental elements, such as rain and dirt.

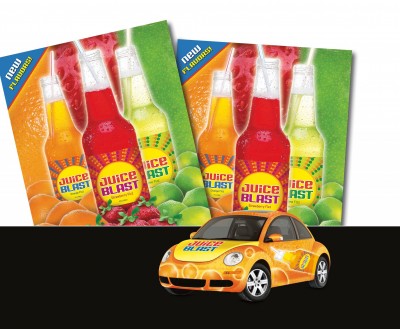

Wide-format prints, in contrast, are easier and more cost-effective to produce and offer greater versatility for many different types of signage applications, including posters, floor graphics, building wraps, vehicle graphics, murals, banners, backlit displays and production backdrops. And a well-executed placement of a wide-format print can achieve far greater overall visibility than a series of screens displaying video content.

With these factors in mind, there has been a recent trend of printed and digital displays coexisting successfully in shopping malls, transportation hubs and public areas, exploiting the respective benefits of each medium.

Reformulating solvent inks

Technological advances in wide-format printing will continue to change the way people think about signmaking by simplifying processes to produce high-quality jobs ahead of schedule, allowing sign shops to take on more projects and increasing their bottom line.

Indeed, wide-format printing has come to represent its own industry sector, which is adapting as new technologies emerge. Manufacturers are focusing on innovative printing configurations with relation to greater energy efficiency, cost-effectiveness and output appeal.

[2]

[2]Solvent ink manufacturers are improving formulations to make them less harmful for the environment and for people’s health.

One example of a stable, reliable, proven technology that is now seeing further improvements is solvent-based inkjet printing. While solvent inks are already cost-effective and highly flexible, enabling printing on a wide range of uncoated vinyl substrates for everything from billboards to vehicle wraps, signmakers are demanding still-better image quality, faster printing speeds, reduced total cost of ownership (TCO) and improved printhead designs with less need for maintenance.

Only by keeping these demands in mind can advances in solvent ink and printhead technologies deliver sufficient value, performance and quality to the sign, vehicle graphics and fine-art reproduction markets.

The wide-format industry will also see innovations to make solvent-based printing ‘greener,’ i.e. less harmful for the environment and for people’s health. Manufacturers are improving formulations by using different types of solvents, avoiding harmful nickel compounds and delivering virtually odour-free printing, with no need for external dryers, special ventilation or air-purification systems.

These improvements are noteworthy because, while ultraviolet-curable (UV-curable) and ‘latex’ durable aqueous inks have certain advantages for some applications, solvent-based inks still offer the best overall combination of image quality and outdoor durability, along with low running costs. Commercial printing operations can thus integrate improved ‘green’ ink technology without sacrificing output quality.

Water-based white

White inks play a vital role in printing on transparent films, such as those used for window graphics, as a layer of white has to be laid down first as a background before other colours are added. Water-based white inks can be conveniently and inexpensively used for printing proofs on these films. Proofs might be output from the same machine used for production printing or by using a dedicated proof printer.

[3]

[3]Today’s wide-format printers offer greater versatility for producing different signage applications, including posters, floor graphics, murals, banners and backlit displays.

Steps to improve sustainability

In the past few years, the wide-format printed graphics market has seen a lot of this type of improvement in terms of sustainability. Many sign shops have realized an environmentally responsible approach—with expanded product recycling programs, ‘green substrates’ and more energy-efficient machines—is simply a better way of doing business.

These transitions and sustainability initiatives, however, have sometimes been very challenging. With digital inkjet graphic production, for example, much of the output has tended to be printed or mounted on substrates that are costly to recycle, if they can be recycled at all.

Many sign shops want to support practices and technologies that have less impact on the environment, but are hesitant to pay higher costs to ‘go green.’ Fortunately, some improved inkjet printing systems—e.g. with lower power consumption—have been developed without having to charge signmakers a premium.

Overall, the wide-format printing industry still has a long way to go to achieve ideal sustainability, but each step forward is an essential investment in the future. ‘Business as usual’ will not help the industry reach its goals in terms of minimizing consumption of energy and resources, recycling materials, reducing the use of harmful substances and eliminating waste. The key is to implement environmental management systems (EMSs), with a continual focus on improving eco-performance at each stage of graphic production, transportation and use.

Reed Hecht is a professional imaging product manager for Epson, which manufactures wide-format printers. For more information, visit www.epson.ca[4].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/JUICEBLASTBEETLE_r7_shd_clip1.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/epsonstylusproinks-2.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/epsonsurecolorsuprema.jpg

- www.epson.ca: http://www.epson.ca

Source URL: https://www.signmedia.ca/making-a-big-impression/