Laser Cutting: Making a living on the edge

by all | 4 April 2013 8:30 am

[1]

[1]Photos courtesy Trotec

By Jon Colley

There are a variety of methods available to today’s signmaker for cutting rigid and flexible substrates, including computer numerical control (CNC) router tables, flatbed tangential blade cutting systems, vinyl cutters and more. Most of these systems deliver acceptable results, but when it comes to cutting acrylic, paper, cardstock, medium-density fibreboard (MDF), polystyrene and fabrics, a carbon dioxide (CO2) laser system is a strong alternative to traditional methods, with the potential for a lower overall total cost of ownership (TCO).

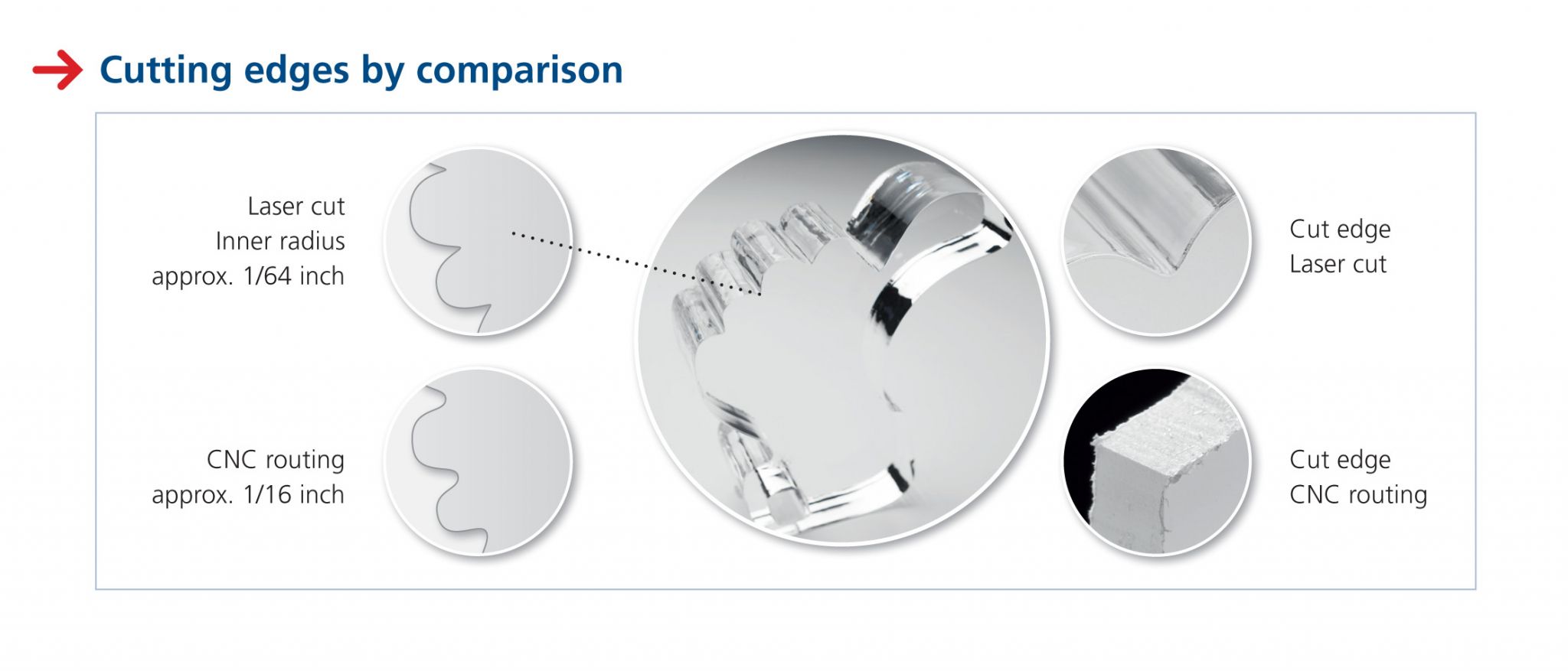

With signs and displays installed almost everywhere, the market push is on for more intricate designs to better grab the attention of the target audience. Cutting small and detailed shapes, however, can be difficult with non-laser technologies, as there are issues with tool size, holding the parts down and, in the case of acrylic, the quality of the resulting edge.

A laser does not run into these issues. The cutting beam is very narrow in diameter and does not move small parts the way a traditional router head does.

How it works

When cutting, the laser intensely focuses energy in a very small area to burn or melt the material. With plastics, a small amount of air is also used to eliminate any flames and to push the molten plastic through the width of the cut. With non-plastics, the material simply burns off as smoke.

In both cases, the smoke is removed from the cutting system using an exhaust fan. The smoke can also be removed from the surrounding air by using a filter system.

Cutting acrylic has proven to be the most profitable application for lasers in the sign industry, due in part to the aforementioned edge quality, but also because the work can be done all in one step. No edge polishing is required, because the laser both cuts and flame-polishes at the same time.

As mentioned, a laser enables the cutting of intricate shapes and designs that would not be possible with traditional router technology. A focused laser beam is, in essence, an approximately 0.4-mm (0.016-in.) diameter cutting tool that does not wear out. Small-diameter tools for CNC routers, by comparison, are more susceptible to wear, breaking and clogging when cutting acrylics. So, it is easy to see how laser systems yield long-term cost savings in terms of tooling.

[2]

[2]No edge polishing is required, because the laser both cuts and flame-polishes at the same time.

Since a laser cuts with heat, the process is very quiet compared to the typical noises associated with router spindles and tools cutting acrylic. Also, as the acrylic vapour is removed by the exhaust system, there is no need to spend time cleaning up the chips and debris that would be left behind by a router.

As a contact-free method of cutting, a laser does not push the material like a router head would, so there is no need to clamp or tape the substrate or pieces down or use a vacuum table to hold it in place. A lot of time is saved, especially on jobs with smaller parts.

Materials that can commonly be laser-cut include acrylic, wood, MDF, foamboards, polystyrene, films and textiles. When a synthetic textile is cut, the laser’s heat melts the edge, so it will not fray like a knife-cut edge would.

Contour cutting

Ultraviolet-curing (UV-curing) inkjet printers have become today’s top tool of choice for printing onto rigid substrates like polystyrene and acrylic, but the next question is how to contour-cut these substrates with acceptable quality and registration to the print.

The fastest and most accurate way to achieve perfect registration in a production environment is an optical vision recognition system. These are available on some laser cutting systems and can be added to others.

In this context, a vision recognition system uses a small camera mounted to the laser head to identify the printed registration marks on the material. Then, software automatically adjusts the cutting vectors to correct for any offset, skew, linear distortion or non-linear distortion.

This functionality allows the operator to quickly cut substrates with high precision, without having to spend time manually checking the registration for each piece. Productivity is improved, the quality of end products is more consistent and scrap is minimized.

Today’s cutting software supports most common file formats, including Adobe Illustrator (AI), Photoshop Document (PSD), PostScript (PS), Encapsulated PostScript (EPS), Portable Document Format (PDF), Drawing (DWG) and Drawing Exchange Format (DXF). Plug-ins are available to automate the creation of registration marks in popular graphic design software packages. And vision process can be integrated with popular raster image processor (RIP) packages, such as those from Caldera, ColorGate and Ergosoft.

Engraving

Laser systems have many benefits in terms of cutting, but they can also be used for engraving, allowing sign shops to expand their offerings.

Engraved plastic signs, for example, are highly durable. Cast acrylic can be engraved with finely detailed logos and images, then edge-lit with light-emitting diodes (LEDs) for locations that require illuminated signage.

[3]

[3]

Lasers can similarly be used to engrave metal and wood signs, but they can also open wholly new markets for a sign shop, such as cut-and-engraved wedding invitations or direct mail.

Answering the demand

As customers demand unique items and higher quality, the sign industry has been challenged to make production processes easier and faster. Laser cutting and engraving systems combined with optical registration can meet many of these challenges.

A standard laser interface and vision registration system can fit relatively seamlessly into a sign shop’s workflow, given their compatibility with existing RIP and design software. Setup is fast, tooling costs lower and scrap reduced. Meanwhile, higher-quality finished products will keep customers coming back for more.

Jon Colley is the Trotec division director for Trodat Marking Canada in Mississauga, Ont., which offers laser engraving, marking and cutting systems. For more information, visit www.troteclaser.com[4] and www.rayjetlaser.com[5].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/engraving_signs_030.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/flame-polished-cut-edges.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/Cutting-edges-by-comparison.jpg

- www.troteclaser.com: http://www.troteclaser.com

- www.rayjetlaser.com: http://www.rayjetlaser.com

Source URL: https://www.signmedia.ca/making-a-living-on-the-edge/