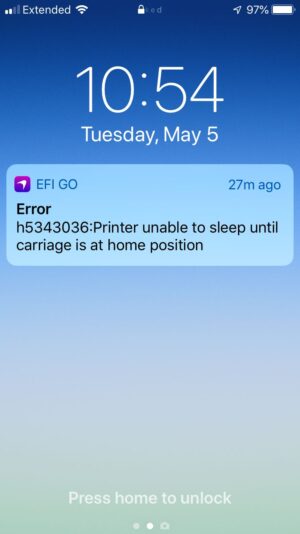

Managers can be confident there are no significant downtimes even when they are not on the floor or onsite with production stoppage alerts.

Conversely, an app with an alert can give essential personnel notifications quickly no matter where they are, so users can quickly resolve a situation without ongoing distractions. Managers can be confident there are no significant downtimes even when they are not on the floor or onsite with production stoppage alerts. The timing of these alerts is often programmable by role. For example, operators might want to be notified after a press is idle for 10 minutes, while managers might want theirs set for 30 minutes or an hour. This approach allows them to perform other tasks required to run their business while also managing their operational staff.

Job ink accounting is another valuable capability offered by cloud-based tools. Tracking the ink consumption of each colour for each job, for example, provides valuable data that can improve profitability. By combining this data with user-entered ink and media prices, one can take the guesswork out of costing jobs. Managers can accurately price future work based upon precise ink utilization data for each production device, helping ensure margins are profitable.

There are many ways production managers can use this data, such as keeping ink and substrate vendors honest by tracking actual supply utilization. The data also provides opportunities to detect slowdowns or productivity gaps between shifts. Managers can also use it to identify excessive ink purging and ink use differences between presses to possibly identify setup training issues. How the data is used depends upon the issues at hand. Additionally, these systems should not operate in a vacuum, and many connect with additional solutions for more accurate, automated accounting information.

Production analytics further drive smart business decisions. Businesses can perform better over time when they can monitor and compare printer performance in terms of jobs printed, cancelled, or errored out, the amount of ink consumed, and/or the square metres printed. Analytics also allow users to see the cumulative time a device has spent printing, idle, awaiting user input, or in an error state. This information can be viewed as tables or graphs to help identify opportunities and can be compared between groups of machines. Users can employ these capabilities to find out which of their printers produced more over the past year, for example, or to compare performance between downtown and suburban locations in the last week. From there, it is possible to drill down to understand why a particular printer is performing better or worse than others.

Additionally, managers can leverage historical printer data in many ways. One obvious use is to identify problem presses and how their performance varies over time. This might result in changes to preventative maintenance, updates to staff training, or even press replacement. However, historical trends can also be used to identify productivity differences between shifts or locations for implementing training or management changes. In addition to this, knowing how much each press can really produce assists in load balancing across presses.

Cloud-based analytics tools provide the information operators and floor managers need to get the most out of managers’ investment and make profitable pricing decisions. One particularly effective feature is certain tools’ ability to passively collect data through digital front-end (DFE) equipment. With passive data collection, operators do not waste time entering information, and managers can be confident the data is accurate and complete.

By employing cloud-based solutions, users can get more productivity out of their printer investments. These tools act as an extra set of eyes on a business’s printers, allowing managers to make informed business decisions and react to productivity issues quickly.

Gregory Cholmondeley is president of Cholmonco. and PRINTelligence Consulting. He has an engineering and marketing background, with nearly 40 years of experience in software and electronics design, strategic planning, marketing, research, and customer engagement. He has spent most of his career focusing on workflow automation, digital productivity, and other innovative print-related solutions. He can be reached at gregc@cholmonco.com.