The sign shop is currently working on several wayfinding projects for schools, large corporations, and government agencies.

SMC: What equipment do you currently use to complete your sign projects?

KS: At the moment, we have three printing machines—Agfa Titan, HP 360, and HP 1500—that we exclusively use to print all of our signage. Not only do our green printers produce good quality output, but also use low volatile organic compounds (VOC) and non-solvent inks, which help in reducing the amount of off-gassing.

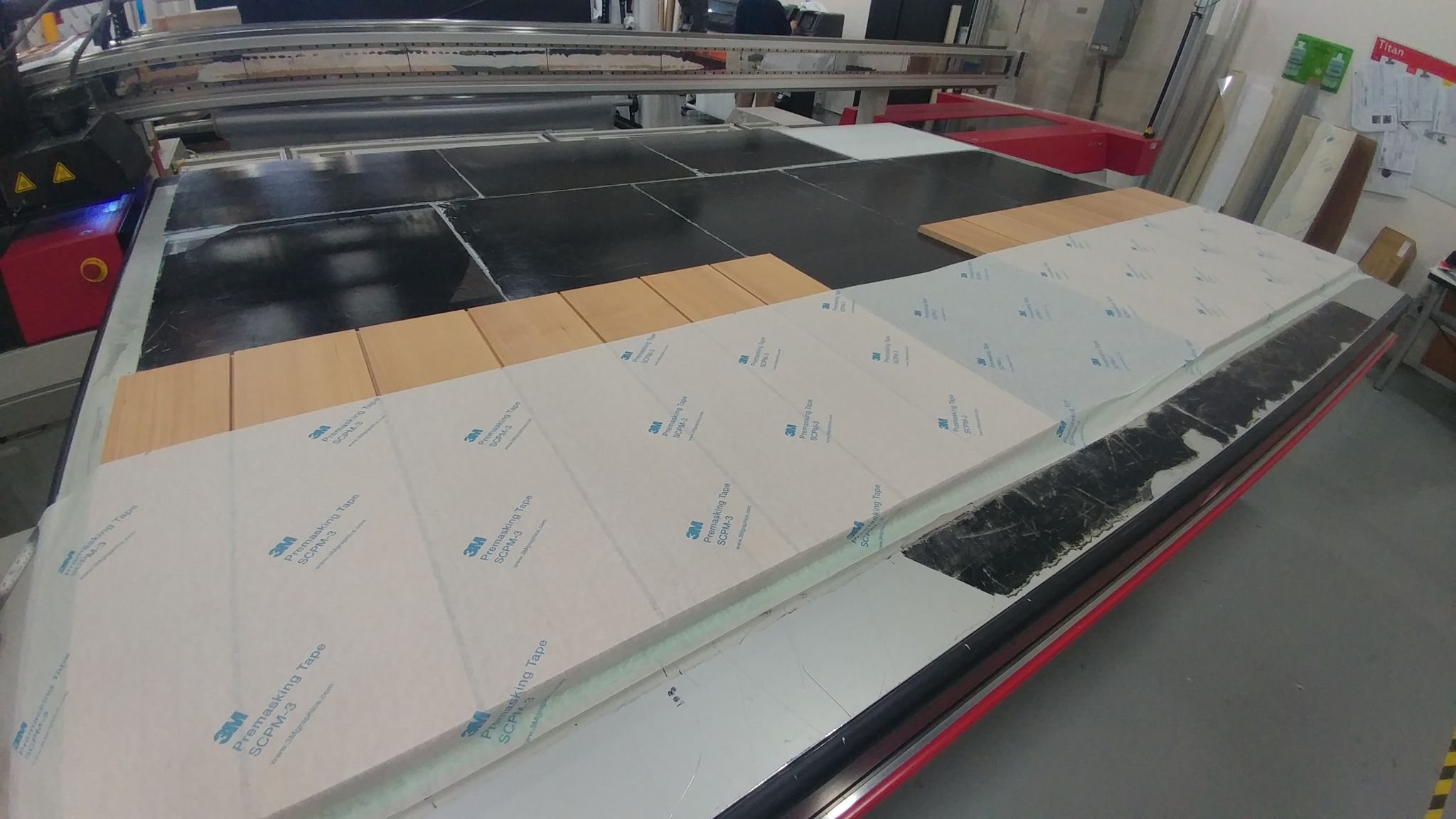

We also have a Graphtec Plotter and Zund Cutter for all our custom-cutting needs. The former is used for handling contour-cut lettering from coloured vinyls, while the latter gives us the freedom to cut rigid sheets and rolled media precisely. Apart from these devices, we have a couple of finishing stations where we sew, hem, and grommet banners.

SMC: What does your planning and design process involve?

KS: As with all orders, the process starts with a customer’s inquiry via e-mail, website, or phone. Each query is reviewed independently by a sales representative who determines the next step. The majority of print jobs follow a standard process—from sales to customer service representatives (CSRs), followed by prepress, production, shipping, and accounting.

Large-scale projects require additional co-ordination between stakeholders. In such cases, we sit with all the departments involved—during the pre-production stage—to go over job details, such as materials, schedules, and installation requirements. We also conduct a thorough site check, which involves confirming sizes, adhesion testing for surfaces, and equipment requirements for unusual spaces. Each process requires a detailed plan and timeline to ensure the order is delivered on time and within budget.

SMC: How is technology changing your business?

KS: Technology and printing go hand in hand. We keep tabs on market direction to stay up-to-date with the latest print trends. That said, the print industry can be a little slow to adopt new technology, as it takes time and effort to reorganize the print workflow and accommodate new processes. The job mandates a judicious balance of integrating new technology and anticipating client needs.

Today, there is a plethora of customer relationship management (CRM) and production management systems that are constantly improving the automation of workflow from start to finish. We try to benefit from these by having dedicated team members research, test, and trial run the software to further improve our work efficiency in meeting clients’ needs. We have also created a system to speed up workflow, such as estimating, quoting, creating job orders, and syncing everything with accounting.

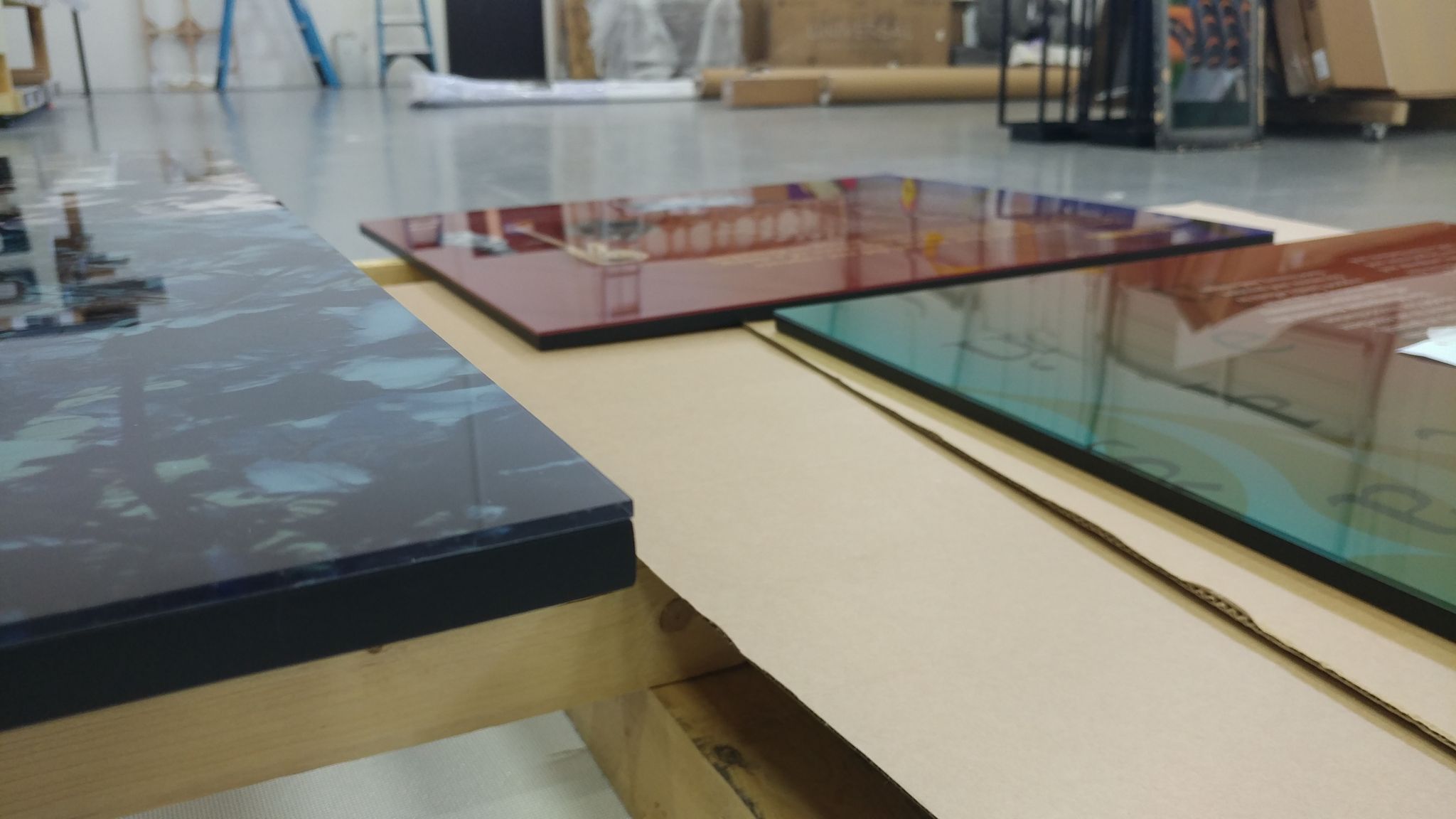

Recently, the company has implemented low VOC inks on printing machines. This switch allows us to take advantage of new non-PVC vinyls and offer clients another way to collect Leadership in Energy and Environmental Design (LEED) accreditation for being focused on air quality within the work environment.

The company won the 2010 Olympic Games self-adhesive vinyl printing contract where it was able to roll a year’s turnover in just under three months, dressing all the event venues with the massive Canadian flag, including the Rosewood Hotel Georgia in Vancouver.

SMC: What is the key to staying successful in the industry?

KS: People, people, people! Good employees are the key to staying competitive in the industry. They are the driving force behind a company’s creativity and success.

The second factor is innovation—whether it is the introduction of new printers, products, or services, it is vital to continue diversifying the shop’s product line.

One cannot afford to become stagnant in this rapidly evolving industry. Investing time and money in the business and taking care of one’s clients can help a company stay ahead in the game.

SMC: What are the future plans for your business?

KS: We are currently investing in new printers and cutters to help speed up production and meet tighter deadlines. We are also focused on introducing environmentally friendly and high-tech products into our workflow. Alongside, we are pushing the new 3M solar and security films that are really popular this summer, while also pursuing multiple wayfinding signage projects. The future definitely looks bright!