Multigraphics: A journey like no other

by | 23 August 2019 8:30 am

By Sonia Yooshing

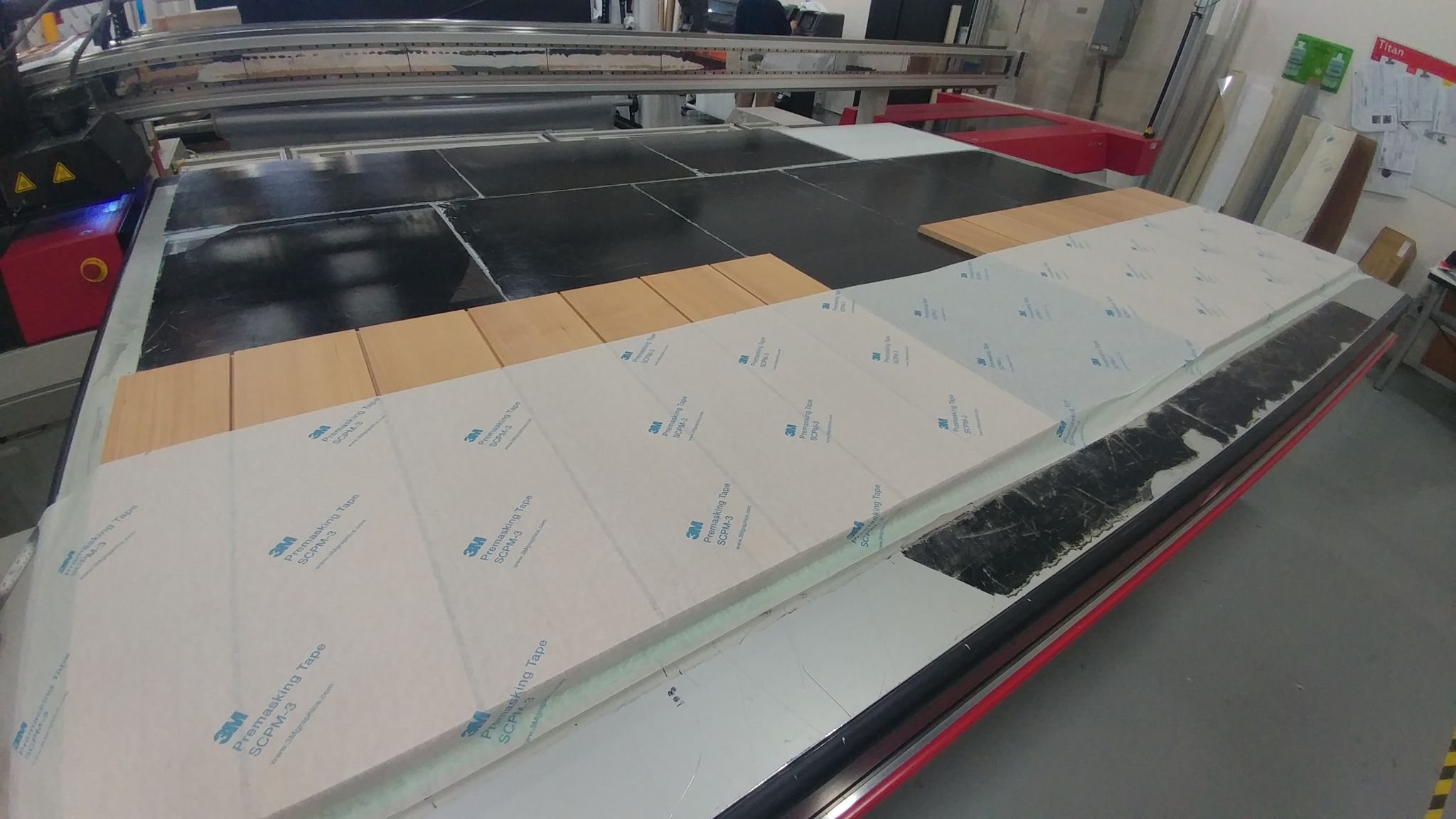

[1]

[1]Since its inception, the sign shop has relocated to three different facilities (each larger than the previous) to accommodate its steady growth and to establish itself as a versatile company.

Multigraphics was founded in the U.K. in 1979 as a packaging printing company by the Clark family. Within three years, the shop began to specialize in large-format screen printing, specifically banners, after purchasing the largest single colour screen printing machines in Europe, which helped them penetrate the grand-format market.

In 1999, the company purchased its first 3.7- x 1.6-m (12- x 5-ft) five colour in-line banner printing machine which, at the time, was the first of its kind outside of the U.S. This investment significantly improved print quality and delivery dates; thereby, transforming the company’s overall workflow. Soon after, the firm purchased two more colour machines and ran those 24-7, driving sales upwards of $18 million.

Multigraphics enjoyed a healthy run for another five years until 2004, when it was acquired by the investment firm 3i Group, which was later absorbed by DS Smith, a European corrugated packaging company.

In January 2005, Matthew Clark (current president) relocated to Vancouver, where he saw an opportunity to re-establish his business, but this time, using digital technology alone. The first sample prints were created on a Durst 600 flatbed printer, which could also print in white. The equipment worked in conjunction with a Zund cutting machine to create banners up to 3200 mm (126 in.) wide.

Despite its humble beginnings, the company quickly expanded, winning the 2010 Olympic Games self-adhesive vinyl printing contract where it was able to roll a year’s turnover in just under three months, dressing all the event venues with tha Canadian flag.

Since its inception, the sign shop has relocated to three different facilities (each larger than the previous) to accommodate its steady growth and to establish itself as a versatile company.

Sign Media Canada recently spoke with Khuram Shahzad, head of digital marketing at Multigraphics, to learn more about the company’s philosophy, its signmaking process, and what the future holds for the business.

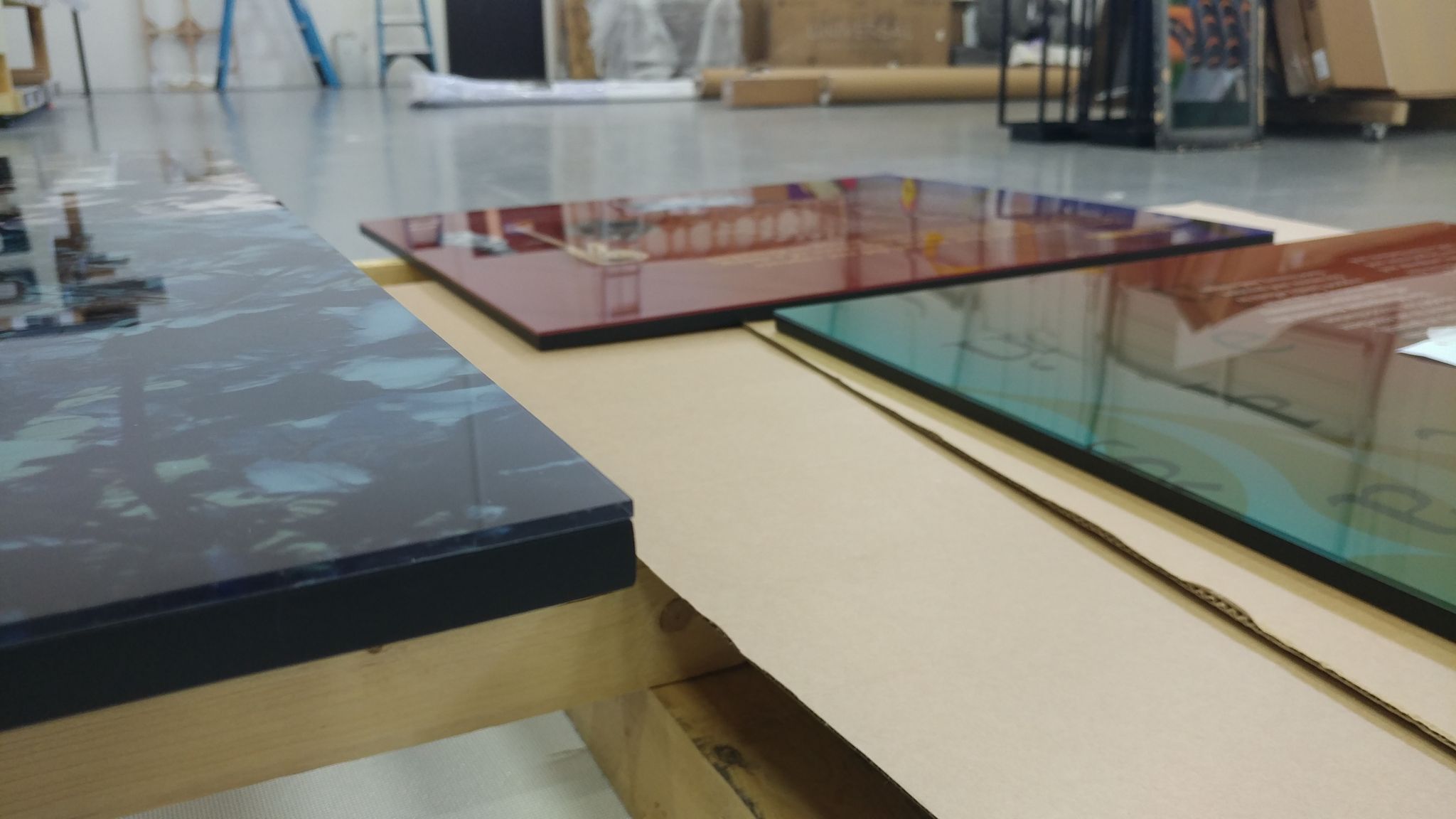

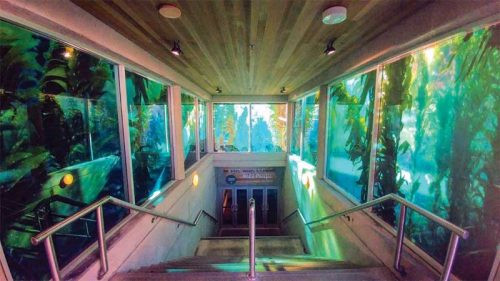

[2]

[2]Multigraphics supported the new expanded look of the Vancouver Aquarium by designing graphics to create a unique aquatic experience for visitors and inhabitants alike.

Sign Media Canada (SMC): How large is the facility?

Khuram Shahzad (KS): We recently moved from a 1022-m2 (11,000-sf) facility to one that is 1580 m2 (17,000 sf) to accommodate the continuous growth we have had in the last few years, both in terms of production and staff. Currently, we have 27 full-time employees—in different departments—who work diligently to ensure the quality of our brand remains true to its core.

SMC: What makes your company unique?

KS: Our uniqueness lies in our diversity—not only in terms of the variety of projects, but also our team members. For example, a few of our sales and production staff have been in the industry for more than 20 years. From old school printing to modern digital production—they have seen it all and know what works best for our clients. This wealth of knowledge and experience is a great asset when it comes to recommending solutions to customers, which often involve ways to reduce costs while retaining the essence of their design.

Whether it is retail signage, exhibition graphics, window films, wallpapers, wayfinding signs, architectural finishes, or site signage, Multigraphics covers the gamut. Our portfolio comprises an eclectic mix of projects, and our ability to produce custom (and very complex) signs makes our brand exclusive. Our client base ranges from architects to developers who are constantly seeking innovative designs that we ensure we can bring to life in the most effective and feasible manner possible.

Also, as a 3M Select Gold Partner, we use exclusive, highly engineered media such as Fasara films, Di-Noc architectural finishes, and solar and security films. Offering these products and warranties not only gives us an edge over our competitors, but also adds credibility to our quality of work.

SMC: What type of signage does your shop primarily make?

KS: It is hard to pick a single product as we create a range of signs on a daily basis. That said, our top three include banners, window graphics, and dimensional letters. Each of these can be further subdivided into specific items. For example, banners can include everything from construction hoardings to full building wraps, while window graphics are comprised of clear vinyl prints, frosted films, and 3M specialty finishes. Especially popular with city developers, 3D letters help create a bold and unique impact when promoting new construction sites or presentation centres.

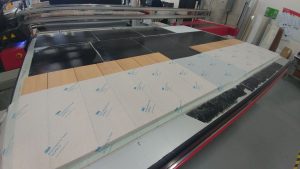

[3]

[3]The Unwritten exhibition was designed to showcase and highlight the eight pillars of The Living City, which would further provide a glimpse of the Oakridge Centre shopping mall’s redevelopment project.

SMC: What type of work have you been handling recently?

KS: Since the beginning of the year, Multigraphics has been busy with creating immersive environments for real-estate presentation centres. City developers, who also make up a large portion of our clientele, are constantly on the lookout for innovative solutions to create high-end presentation centres that drive sales. We have earned a reputation for executing these projects with accuracy and precision across the West Coast.

Some of our most recent projects include Vancouver House, Japan Unlayered, Butterfly, and The Living City at Oakridge Centre. We also created signage for the University of Fraser as well as Seaspan’s new 7800-m2 (83,959-sf) facility. This year, we designed graphics for the Association for Mineral Exploration (AME) Conference, TED Conference, Google Cloud Relay, and Vancouver International Auto Show. We have successfully completed a few tourism projects, too, such as Telus World of Science in Edmonton, Vancouver Aquarium, and FlyOver Canada. We are currently working on several wayfinding projects for schools, large corporations, and government agencies.

SMC: How much of the signmaking process is handled in-house?

KS: Most of our fabrication work is done in-house, and we are constantly looking for ways to upgrade our equipment that add to our capabilities. Our sign shop specializes in custom-designed products, which make every project exceptionally unique. We have fostered relationships with local vendors, fabricators, and installers so, in the event, we are unable to produce an item in-house, we have the resources to call upon.

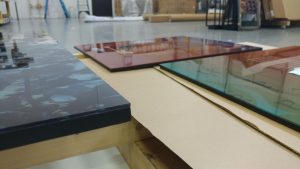

[4]

[4]The sign shop is currently working on several wayfinding projects for schools, large corporations, and government agencies.

SMC: What equipment do you currently use to complete your sign projects?

KS: At the moment, we have three printing machines—Agfa Titan, HP 360, and HP 1500—that we exclusively use to print all of our signage. Not only do our green printers produce good quality output, but also use low volatile organic compounds (VOC) and non-solvent inks, which help in reducing the amount of off-gassing.

We also have a Graphtec Plotter and Zund Cutter for all our custom-cutting needs. The former is used for handling contour-cut lettering from coloured vinyls, while the latter gives us the freedom to cut rigid sheets and rolled media precisely. Apart from these devices, we have a couple of finishing stations where we sew, hem, and grommet banners.

SMC: What does your planning and design process involve?

KS: As with all orders, the process starts with a customer’s inquiry via e-mail, website, or phone. Each query is reviewed independently by a sales representative who determines the next step. The majority of print jobs follow a standard process—from sales to customer service representatives (CSRs), followed by prepress, production, shipping, and accounting.

Large-scale projects require additional co-ordination between stakeholders. In such cases, we sit with all the departments involved—during the pre-production stage—to go over job details, such as materials, schedules, and installation requirements. We also conduct a thorough site check, which involves confirming sizes, adhesion testing for surfaces, and equipment requirements for unusual spaces. Each process requires a detailed plan and timeline to ensure the order is delivered on time and within budget.

SMC: How is technology changing your business?

KS: Technology and printing go hand in hand. We keep tabs on market direction to stay up-to-date with the latest print trends. That said, the print industry can be a little slow to adopt new technology, as it takes time and effort to reorganize the print workflow and accommodate new processes. The job mandates a judicious balance of integrating new technology and anticipating client needs.

Today, there is a plethora of customer relationship management (CRM) and production management systems that are constantly improving the automation of workflow from start to finish. We try to benefit from these by having dedicated team members research, test, and trial run the software to further improve our work efficiency in meeting clients’ needs. We have also created a system to speed up workflow, such as estimating, quoting, creating job orders, and syncing everything with accounting.

Recently, the company has implemented low VOC inks on printing machines. This switch allows us to take advantage of new non-PVC vinyls and offer clients another way to collect Leadership in Energy and Environmental Design (LEED) accreditation for being focused on air quality within the work environment.

[5]

[5]The company won the 2010 Olympic Games self-adhesive vinyl printing contract where it was able to roll a year’s turnover in just under three months, dressing all the event venues with the massive Canadian flag, including the Rosewood Hotel Georgia in Vancouver.

SMC: What is the key to staying successful in the industry?

KS: People, people, people! Good employees are the key to staying competitive in the industry. They are the driving force behind a company’s creativity and success.

The second factor is innovation—whether it is the introduction of new printers, products, or services, it is vital to continue diversifying the shop’s product line.

One cannot afford to become stagnant in this rapidly evolving industry. Investing time and money in the business and taking care of one’s clients can help a company stay ahead in the game.

SMC: What are the future plans for your business?

KS: We are currently investing in new printers and cutters to help speed up production and meet tighter deadlines. We are also focused on introducing environmentally friendly and high-tech products into our workflow. Alongside, we are pushing the new 3M solar and security films that are really popular this summer, while also pursuing multiple wayfinding signage projects. The future definitely looks bright!

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/08/Team-photo.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/08/Vancouver-Aquarium-Kelp-Forest.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/08/Oakridge-Exhibit-12.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/08/Wayfinding-signage-Seaspan-33.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/08/Hotel-Georgia-Building-Wrap-Olympics-2010.jpg

Source URL: https://www.signmedia.ca/multigraphics-a-journey-like-no-other/